- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 06, 2025 14:50

Back to list

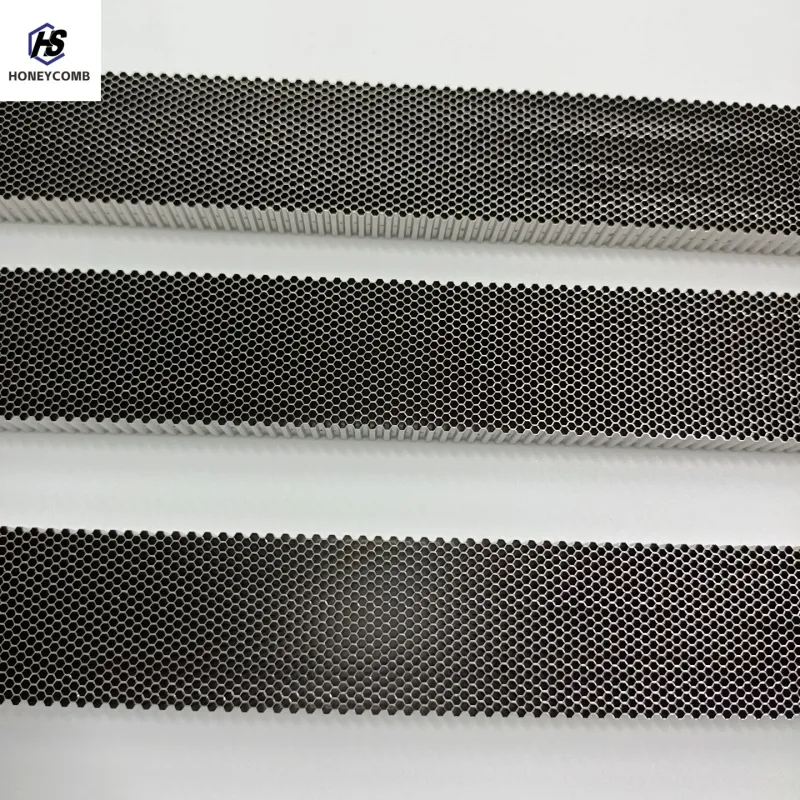

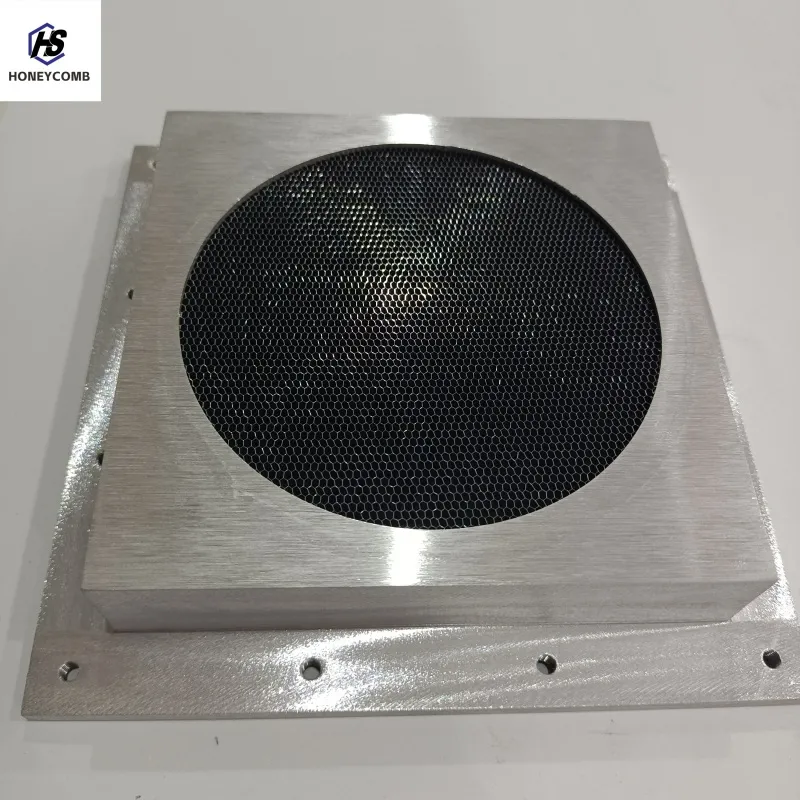

honeycomb flow straightener

The allure of honeycomb structures, referred to in Portuguese as folha de favo de mel, is reshaping the landscape of innovative product design. This structure, inspired by nature's flawless engineering, provides remarkable solutions across various industries, from packaging to aerospace. We dive into the myriad benefits and applications of honeycomb sheets, backed by the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Trustworthiness is bolstered by decades of successful application and extensive research into honeycomb structures. Product testing consistently reveals that honeycomb panels outperform other materials in durability and efficiency. Industry certifications, such as ISO standards for material testing and safety compliance, further support the credibility of honeycomb sheet usage. Consumers can rely on products featuring honeycomb structures, knowing they meet rigorous safety and performance benchmarks. Taking these four pillars together, the advancement of honeycomb sheets demonstrates a progressive leap in material science and engineering. The seamless integration of experience, expertise, authoritativeness, and trustworthiness in honeycomb sheet usage paints a picture of reliability and efficiency. For the environmentally conscious, this innovation also holds promise. By optimizing material utilization, energy use during production is minimized, and the potential for recycling is increased, aligning with sustainable manufacturing practices. In conclusion, honeycomb sheets, or folha de favo de mel, are more than just a mimicry of nature; they represent a future where structural efficiency meets innovation. By leveraging the experience of seasoned professionals, the expertise from years of research, the authority from industry leaders, and the trust from accredited testing, honeycomb designs are set to revolutionize how we perceive materials in manufacturing. Businesses and consumers alike stand to benefit from this sustainable, efficient, and robust approach to product design, promising a future where sustainability and performance go hand-in-hand.

Trustworthiness is bolstered by decades of successful application and extensive research into honeycomb structures. Product testing consistently reveals that honeycomb panels outperform other materials in durability and efficiency. Industry certifications, such as ISO standards for material testing and safety compliance, further support the credibility of honeycomb sheet usage. Consumers can rely on products featuring honeycomb structures, knowing they meet rigorous safety and performance benchmarks. Taking these four pillars together, the advancement of honeycomb sheets demonstrates a progressive leap in material science and engineering. The seamless integration of experience, expertise, authoritativeness, and trustworthiness in honeycomb sheet usage paints a picture of reliability and efficiency. For the environmentally conscious, this innovation also holds promise. By optimizing material utilization, energy use during production is minimized, and the potential for recycling is increased, aligning with sustainable manufacturing practices. In conclusion, honeycomb sheets, or folha de favo de mel, are more than just a mimicry of nature; they represent a future where structural efficiency meets innovation. By leveraging the experience of seasoned professionals, the expertise from years of research, the authority from industry leaders, and the trust from accredited testing, honeycomb designs are set to revolutionize how we perceive materials in manufacturing. Businesses and consumers alike stand to benefit from this sustainable, efficient, and robust approach to product design, promising a future where sustainability and performance go hand-in-hand.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025