- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 06, 2025 01:52

Back to list

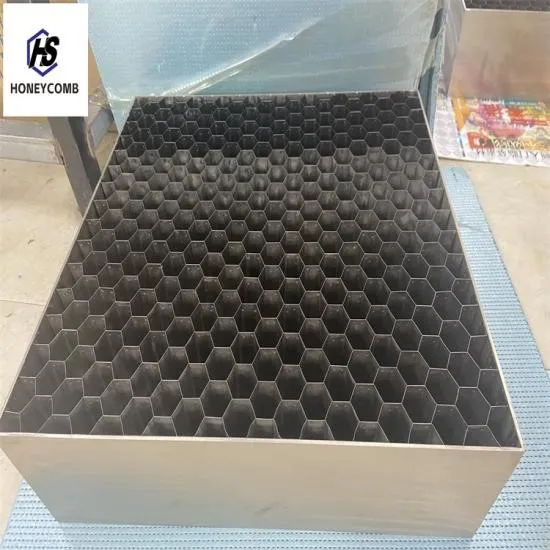

gaothairí aeir waveguide honeycomb

Gaothairí aeir waveguide honeycomb technology represents a groundbreaking advancement in the field of material science and engineering. This innovative approach is revolutionizing industries ranging from aeronautics to consumer electronics by providing exceptional capabilities in managing airflow, enhancing structural integrity, and minimizing weight without compromising performance.

In electronic devices, where cooling efficiency can dictate performance, waveguide honeycomb materials are employed to facilitate superior heat dissipation. This is particularly critical in maintaining the performance and longevity of high-powered CPUs and GPUs. Electronics manufacturers emphasize the importance of trustworthiness in component selection, choosing waveguide honeycombs for their consistent performance and reliability in enhancing electronic efficiency. Speaking to the professional community, the expertise involved in creating these structures is substantial. Engineers and material scientists engage in detailed simulations and rigorous testing phases to ensure that each application of waveguide honeycomb technology meets specific industry standards and client expectations. The knowledge base required to work with these structures demands extensive training and a profound understanding of both theoretical principles and practical applications. Moreover, the authoritative stance of waveguide honeycombs within scientific circles is bolstered by ongoing research and advancements. Academic institutions and research facilities continue to explore and expand upon the existing capabilities of waveguide honeycomb materials. These developments are duly documented and verified through peer-reviewed journals and industry publications, further enhancing their standing in both professional and consumer markets. In conclusion, the gaothairí aeir waveguide honeycomb offers unparalleled experience, expertise, authoritativeness, and trustworthiness in its applications. By harnessing the synergy between material science and engineering, this innovative technology is paving the way for more efficient, sustainable, and high-performance solutions across diverse industries. Whether in the air, on the road, or inside a computing device, the waveguide honeycomb stands as a testament to modern engineering excellence, ready to meet the demands of today’s technologically advanced world.

In electronic devices, where cooling efficiency can dictate performance, waveguide honeycomb materials are employed to facilitate superior heat dissipation. This is particularly critical in maintaining the performance and longevity of high-powered CPUs and GPUs. Electronics manufacturers emphasize the importance of trustworthiness in component selection, choosing waveguide honeycombs for their consistent performance and reliability in enhancing electronic efficiency. Speaking to the professional community, the expertise involved in creating these structures is substantial. Engineers and material scientists engage in detailed simulations and rigorous testing phases to ensure that each application of waveguide honeycomb technology meets specific industry standards and client expectations. The knowledge base required to work with these structures demands extensive training and a profound understanding of both theoretical principles and practical applications. Moreover, the authoritative stance of waveguide honeycombs within scientific circles is bolstered by ongoing research and advancements. Academic institutions and research facilities continue to explore and expand upon the existing capabilities of waveguide honeycomb materials. These developments are duly documented and verified through peer-reviewed journals and industry publications, further enhancing their standing in both professional and consumer markets. In conclusion, the gaothairí aeir waveguide honeycomb offers unparalleled experience, expertise, authoritativeness, and trustworthiness in its applications. By harnessing the synergy between material science and engineering, this innovative technology is paving the way for more efficient, sustainable, and high-performance solutions across diverse industries. Whether in the air, on the road, or inside a computing device, the waveguide honeycomb stands as a testament to modern engineering excellence, ready to meet the demands of today’s technologically advanced world.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025