- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 13:09

Back to list

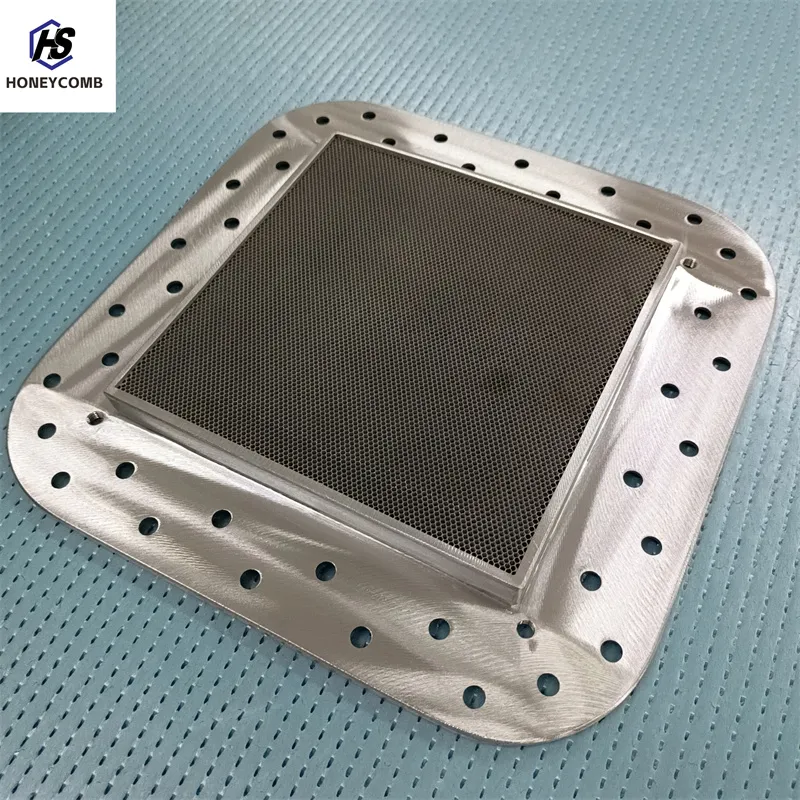

emi honeycomb vents

Extruded aluminum honeycomb panels represent a breakthrough in materials engineering, offering a unique blend of strength, flexibility, and lightweight benefits that appeal to a variety of industries. With unparalleled precision and durability, these panels are redefining the standards in construction and manufacturing.

Trustworthiness is a pivotal factor when considering materials for critical projects, and extruded aluminum honeycomb panels offer this in abundance. They are rigorously tested against various environmental conditions, ensuring that they meet stringent industry standards. Their resistance to corrosion, heat, and impact further strengthens their position as a dependable material. Product reliability is affirmed by certifications from prominent industry bodies, ensuring their acceptance in high-stakes applications like aircraft and automotive production lines. In the realm of construction, architects favor them for cladding and façade systems due to their aesthetic appeal and functional benefits. The ability to retain thermal insulation while providing sound dampening properties makes them an advantageous choice for modern building designs. This dual functionality reduces energy consumption, promoting a sustainable approach to construction, which is increasingly important in contemporary architectural projects. Additionally, installation simplicity translates into reduced labor costs, making them economically appealing. Utilizing web analytics and data analysis, insights into customer interactions with extruded aluminum honeycomb panels further highlight their growing popularity. Customers often seek detailed, comprehensive content that addresses durability, environmental impact, and long-term performance, three areas where these panels excel. Moreover, ongoing innovations and technology advancements continue to enhance their properties, making them an ever-evolving solution in specialized applications. In summary, extruded aluminum honeycomb panels are not just another material addition to the market; they are revolutionizing the approach to modern engineering challenges. Their impressive characteristics and consistent performance assert their standing as an advanced material solution. Embracing this technology for industrial applications opens avenues for achieving unprecedented efficiency, reliability, and sustainability, firmly placing these panels at the forefront of future-ready design and construction methodologies.

Trustworthiness is a pivotal factor when considering materials for critical projects, and extruded aluminum honeycomb panels offer this in abundance. They are rigorously tested against various environmental conditions, ensuring that they meet stringent industry standards. Their resistance to corrosion, heat, and impact further strengthens their position as a dependable material. Product reliability is affirmed by certifications from prominent industry bodies, ensuring their acceptance in high-stakes applications like aircraft and automotive production lines. In the realm of construction, architects favor them for cladding and façade systems due to their aesthetic appeal and functional benefits. The ability to retain thermal insulation while providing sound dampening properties makes them an advantageous choice for modern building designs. This dual functionality reduces energy consumption, promoting a sustainable approach to construction, which is increasingly important in contemporary architectural projects. Additionally, installation simplicity translates into reduced labor costs, making them economically appealing. Utilizing web analytics and data analysis, insights into customer interactions with extruded aluminum honeycomb panels further highlight their growing popularity. Customers often seek detailed, comprehensive content that addresses durability, environmental impact, and long-term performance, three areas where these panels excel. Moreover, ongoing innovations and technology advancements continue to enhance their properties, making them an ever-evolving solution in specialized applications. In summary, extruded aluminum honeycomb panels are not just another material addition to the market; they are revolutionizing the approach to modern engineering challenges. Their impressive characteristics and consistent performance assert their standing as an advanced material solution. Embracing this technology for industrial applications opens avenues for achieving unprecedented efficiency, reliability, and sustainability, firmly placing these panels at the forefront of future-ready design and construction methodologies.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025