- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 11, 2025 11:37

Back to list

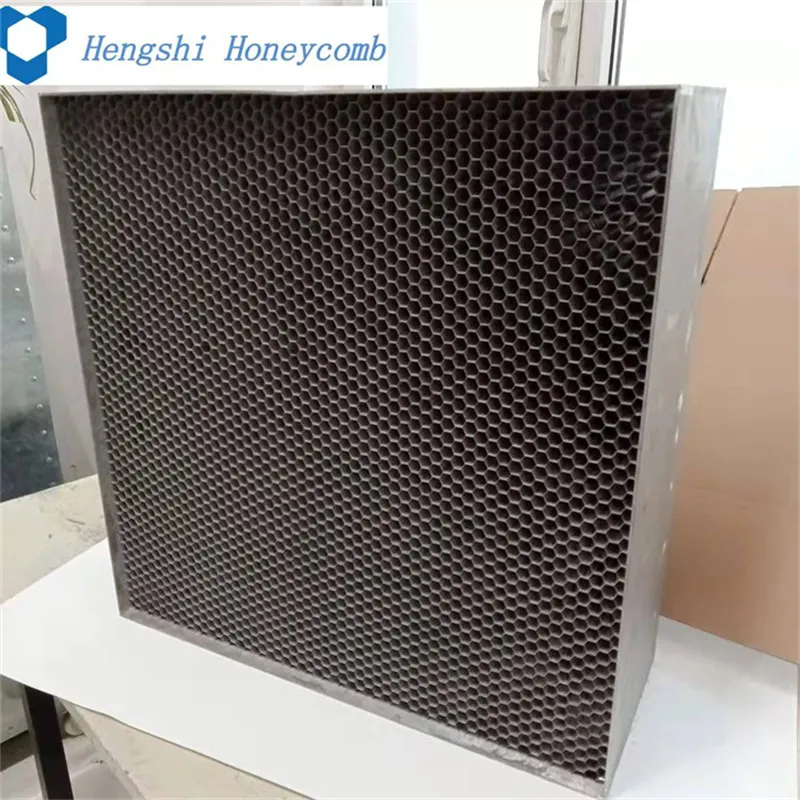

Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener

The carbon honeycomb core, a product that has captured the attention of industries ranging from aerospace to automotive, continues to demonstrate its versatility, durability, and strength. As an expert in material science and its application, the unique properties of the carbon honeycomb core make it a pivotal material in contemporary engineering, offering remarkable benefits that stand unmatched by traditional materials.

The marine industry further demonstrates the adaptability of carbon honeycomb cores. Boats and yachts benefit from the reduced weight, allowing for greater speed and efficiency over water. Moreover, this material’s natural resistance to corrosion and degradation in harsh conditions makes it ideal for prolonged exposure to marine environments. Regarding trustworthiness and safety, carbon honeycomb cores have been subject to extensive testing and certification, ensuring that they meet international safety and performance standards. Industry certifications validate the reliability of this material, offering peace of mind across its multiple applications. As we explore the future potential of carbon honeycomb cores, its impact on sustainability cannot be ignored. The production techniques for carbon composites are advancing rapidly, paving the way for more sustainable sourcing and recycling processes. The rise of environmentally-conscious manufacturing is increasingly integrating carbon honeycomb materials to reduce waste and energy consumption across various sectors. In conclusion, the carbon honeycomb core stands as an exemplar of modern material innovation. Its ability to combine strength, flexibility, and lightness makes it indispensable in cutting-edge applications, providing engineers and architects a reliable and advanced material choice. It's crucial for industries to continue investing in this technology, striving for innovations that not only improve performance but also enhance sustainability and environmental stewardship. As industries push forward, embracing the carbon honeycomb core will be vital in driving future advancements and efficiencies.

The marine industry further demonstrates the adaptability of carbon honeycomb cores. Boats and yachts benefit from the reduced weight, allowing for greater speed and efficiency over water. Moreover, this material’s natural resistance to corrosion and degradation in harsh conditions makes it ideal for prolonged exposure to marine environments. Regarding trustworthiness and safety, carbon honeycomb cores have been subject to extensive testing and certification, ensuring that they meet international safety and performance standards. Industry certifications validate the reliability of this material, offering peace of mind across its multiple applications. As we explore the future potential of carbon honeycomb cores, its impact on sustainability cannot be ignored. The production techniques for carbon composites are advancing rapidly, paving the way for more sustainable sourcing and recycling processes. The rise of environmentally-conscious manufacturing is increasingly integrating carbon honeycomb materials to reduce waste and energy consumption across various sectors. In conclusion, the carbon honeycomb core stands as an exemplar of modern material innovation. Its ability to combine strength, flexibility, and lightness makes it indispensable in cutting-edge applications, providing engineers and architects a reliable and advanced material choice. It's crucial for industries to continue investing in this technology, striving for innovations that not only improve performance but also enhance sustainability and environmental stewardship. As industries push forward, embracing the carbon honeycomb core will be vital in driving future advancements and efficiencies.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025