- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 11, 2025 12:47

Back to list

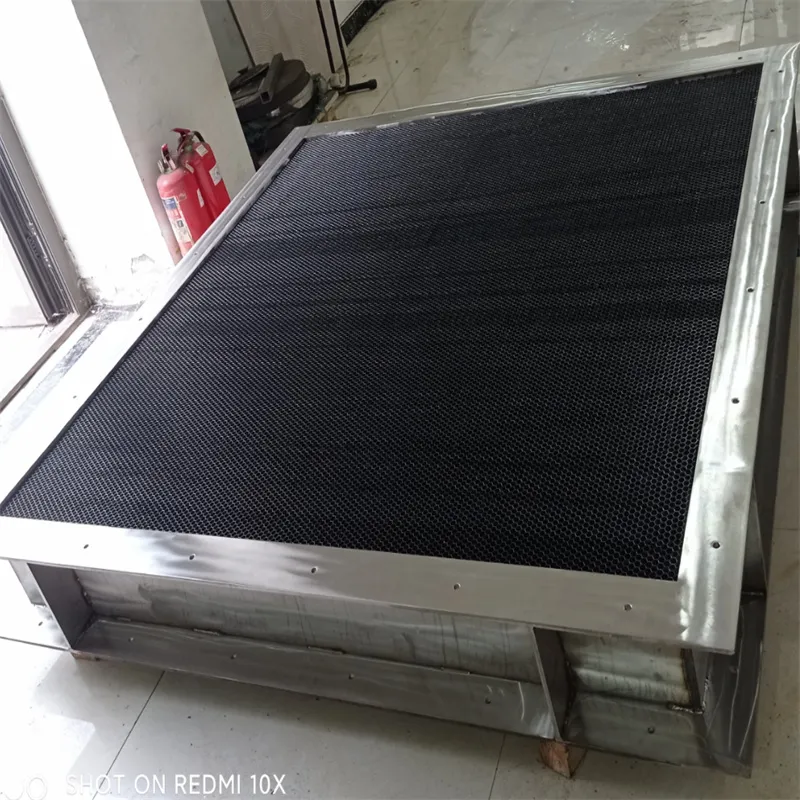

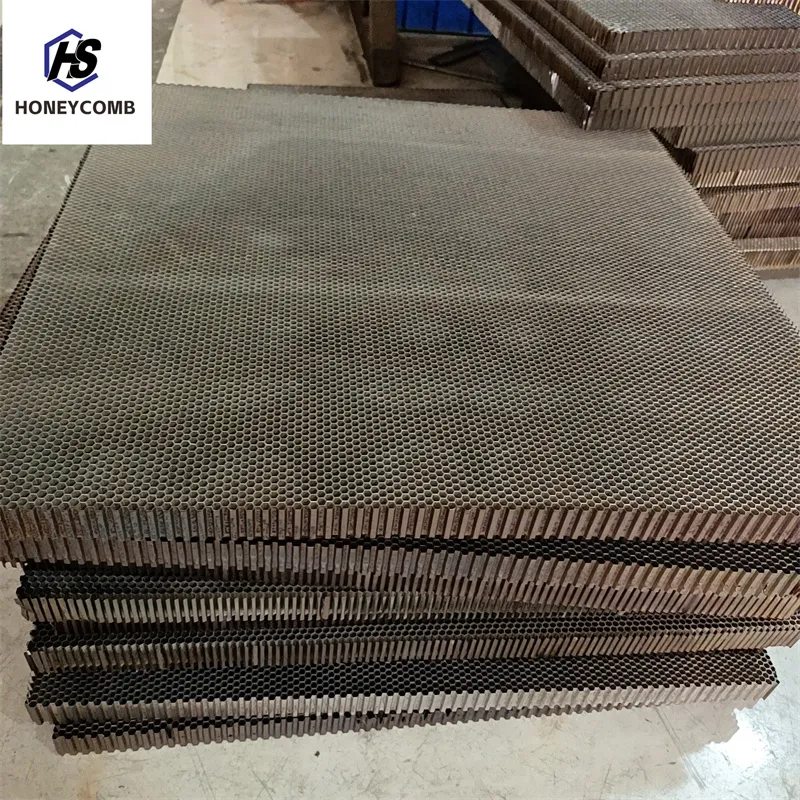

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

The fusion of plastic honeycomb structures with carbon cores represents a groundbreaking advancement in modern engineering and design. These innovative materials are increasingly recognized for their unique properties, offering unparalleled advantages in various sectors such as aerospace, automotive, and construction.

The production of plastic honeycombs with carbon cores is an area where expertise and precision play critical roles. Manufacturers must ensure exact standards to maintain the integrity and performance of these materials. Advanced machinery and cutting-edge technology are pivotal in achieving the intricacy of these structures. Additionally, sustainability remains at the forefront, as manufacturers increasingly explore eco-friendly production methods to minimize environmental impact. As the use of these composite materials becomes more widespread, their authoritative presence in the market grows. Leading companies in various industries are endorsing these materials, not only for their performance but also for their contribution to sustainability. This growing trust is strengthened by continuous research and development, pushing the boundaries of what's possible with engineering materials. Trustworthiness, a vital component for product acceptance, is built through rigorous testing and certification. As these materials become more mainstream, they undergo extensive testing to meet international safety and performance standards. This ensures that any product utilizing plastic honeycombs with carbon cores is not only innovative but also reliable and safe for use. In conclusion, the integration of plastic honeycombs with carbon cores signifies a leap forward in material science and engineering. Their ability to merge lightness with strength, along with their versatility across industries, positions them as a pivotal material for the future. As they gain recognition for their substantial benefits and contributions to eco-friendly practices, their role in shaping the future of design and construction becomes indisputable.

The production of plastic honeycombs with carbon cores is an area where expertise and precision play critical roles. Manufacturers must ensure exact standards to maintain the integrity and performance of these materials. Advanced machinery and cutting-edge technology are pivotal in achieving the intricacy of these structures. Additionally, sustainability remains at the forefront, as manufacturers increasingly explore eco-friendly production methods to minimize environmental impact. As the use of these composite materials becomes more widespread, their authoritative presence in the market grows. Leading companies in various industries are endorsing these materials, not only for their performance but also for their contribution to sustainability. This growing trust is strengthened by continuous research and development, pushing the boundaries of what's possible with engineering materials. Trustworthiness, a vital component for product acceptance, is built through rigorous testing and certification. As these materials become more mainstream, they undergo extensive testing to meet international safety and performance standards. This ensures that any product utilizing plastic honeycombs with carbon cores is not only innovative but also reliable and safe for use. In conclusion, the integration of plastic honeycombs with carbon cores signifies a leap forward in material science and engineering. Their ability to merge lightness with strength, along with their versatility across industries, positions them as a pivotal material for the future. As they gain recognition for their substantial benefits and contributions to eco-friendly practices, their role in shaping the future of design and construction becomes indisputable.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025