- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

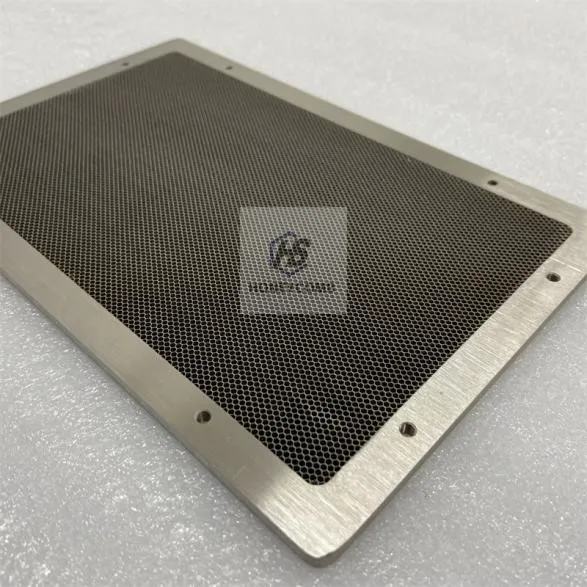

High-Performance Honeycomb Waveguide Air Vents for AI Cooling

Industry Overview & Trend of Honeycomb Waveguide Air Vents

Honeycomb waveguide air vents—as well as their subtypes like EMI honeycomb and honeycomb air vent panels—are vital for next-gen electronics enclosures requiring both optimized airflow and high-level electromagnetic shielding. According to a 2023 Electronic Design market survey, the global EMI shielding market is expected to reach $7.2 billion by 2028, with over 23% CAGR specifically in waveguide vent solutions for 5G, aerospace, and industrial automation.

- Recent Trend: Multi-layered honeycomb vents are favored for their enhanced broadband attenuation in ISO/IEC 61000-4-6 environments.

- Key Drivers: Miniaturization, higher data rates, and environmental compliance (RoHS, REACH).

- Top Growth Regions: North America, East Asia, and Western Europe.

| Parameter | Typical Range | Industry Standard/Test | Reference Product |

|---|---|---|---|

| Honeycomb Cell Size | 3.2–6.35 mm | IEC 61000-5-7 | Honeycomb Waveguide Window/Panel |

| Panel Thickness | 6–51 mm | ANSI C63.5 | Honeycomb Waveguide Panel |

| Material | • Aluminum (5052/6061) • Stainless Steel 304/316 • Brass/Copper |

ISO 9001, ASTM B209 | Honeycomb EMI Vents |

| EMI Attenuation | ≥ 60–120 dB @1-10 GHz | IEC 60068-2-6, MIL-STD-285 | EMI Honeycomb Air Vent |

| Airflow (Free Area) | ≥ 90% | ISO 5167 | Honeycomb Air Vent |

| Corrosion Resistance | Salt spray ≥ 500h | ASTM B117 | Honeycomb Waveguide Panel |

Technical Principle & Manufacturing Process of Honeycomb Waveguide Air Vents

What Makes Honeycomb Waveguide Air Vents So Effective?

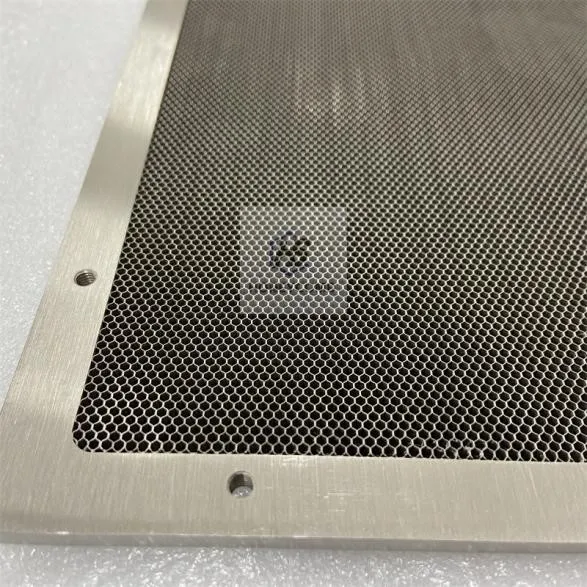

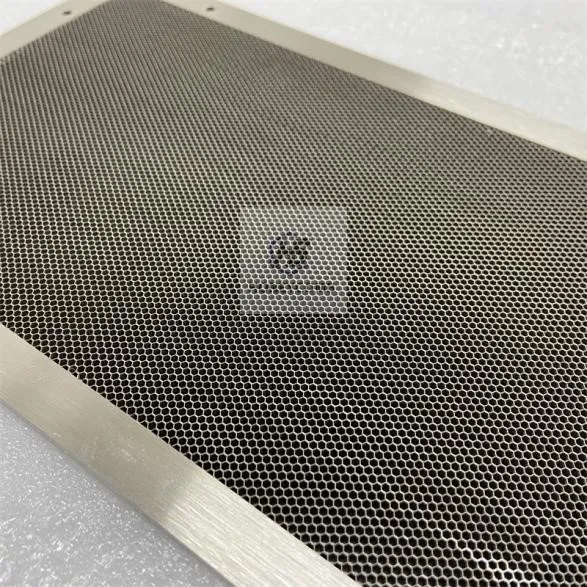

The core principle is utilizing a high-precision metallic honeycomb—whose depth and cell geometry act as a waveguide below cutoff—for maximum EMI attenuation, while the honeycomb passage enables high airflow for cooling or pressurization.

Detailed Manufacturing Flow

1. Material Selection

Choose aluminum (5052/6061), stainless steel, or brass per EMI & corrosion requirements2. Honeycomb Core Fabrication

Layers formed and expanded, precision-cut (CNC/laser); cell size & depth adjusted3. Frame Machining

CNC milled / die-cast to tolerance; anodized or plated for finish4. Assembly & Bonding

Honeycomb core inserted into frame, high-grade adhesive or spot-welded as per ISO 90015. Surface Finishing

Anodizing, chromate, or chemical conversion for enhanced life & corrosion protection6. Testing & Inspection

EMI, airflow & salt-spray (ASTM B117, IEC 60068); delivered with test report

Honeycomb Waveguide Window/Panel—Key Technical Indices & Performance Visualization

The Honeycomb Waveguide Window/Panel by HSHI is engineered for high EMI attenuation, superb airflow, and robust corrosion resistance—meeting or surpassing ISO, ANSI, and MIL standards.

Technical Advantages & Compliance Certifications

- Ultra-High EMI Attenuation: 60–120 dB attenuation per IEC 61000-4-3, far exceeding sheet-metal and mesh venting.

- Maximum Airflow: Free area ≥90% preserving cooling and air exchange compared to solid shielding*

- Excellent Corrosion Resistance: Salt spray ≥500h; all honeycomb waveguide air vents available with anodized, passivated, or chromate surface to ISO 9227 / ASTM B117

- Custom Fabrication: Wide range in cell depth, size, frame geometry, and gasket integration possible—tailored for OEM electronics, HVAC, military

- Certified Quality: ISO 9001:2015, RoHS, REACH, ANSI/AHAM, IEC 60068, plus customer-specific testing

Top Manufacturers of Honeycomb Waveguide Air Vents: Comparative Overview

| Manufacturer | Main Market | Material Choices | Compliance Certifications | Customization Level |

|---|---|---|---|---|

HSHI HSHI |

Global (OEM/Defense/Telecom) | Al, SS, Brass, CU | ISO 9001, RoHS, REACH | Full: cell, frame, surface, size |

| Leader Tech | North America | Al, SS | ISO 9001, MIL-STD-285 | Medium: grid, frame |

| Holland Shielding | Europe/Global | Al, Brass, SS | ISO 9001, RoHS, MIL | Medium |

| Parker Chomerics | Global (Aerospace) | Al, Cu | ISO, REACH, RoHS | High: seals, mounting |

Custom Honeycomb Waveguide Air Vent Solutions

HSHI offers true end-to-end customization for honeycomb waveguide window/panels:

- Cell Size/Depth: From 3.2mm (fine) to 6.35mm (high flow); panel depth up to 51mm for extreme EMI

- Material & Coating: Anodized/Alodine/Chromate as per corrosion or appearance needs

- Frame Geometry: Press-fit, baffle/knife, square, or flanged edge with or without EMI gasket

- CNC Precision: All panels and frames produced to sub-0.1mm flatness or per customer/military drwgs

- Mounting Type: Pre-drilled holes, captive fasteners, custom brackets

- EMI Gasket Integration: Monolithic or insertable EMI gasket for up to 130 dB shield

Typical Application Cases of Honeycomb Waveguide Air Vents

- Integrated 4.8mm honeycomb, 93% free area, chromate anodized; EMI shield tested ≥108dB @5GHz

- Operational in saline coastal regions (≥530h salt spray passed)

- Fully compliant with IEC 61000-4-3 & ASTM B117

- Custom E-type frame, aluminum 6061, 6.35mm thick core

- MIL-STD-285/ECE R10-certified EMI attenuation >100dB, mechanical shock tested

- Integrated knife-edge EMC gasket for full enclosure sealing

- Stainless steel honeycomb air vent, passivated, ≥500h salt spray

- 60dB+ EMI shield, tested to IEC 60068 environmental cycling

- Enabled significant energy savings on climate systems by allowing large area free flow while maintaining EMI integrity

Product Specifications: Honeycomb Waveguide Window/Panel

| Model | Cell Size | Panel Thickness | Material | EMI (dB)@3GHz | Surface Finish | Typical Use |

|---|---|---|---|---|---|---|

| HSHI-43A | 4.3mm | 10mm | 5052 AL | 100 | Anodized | Server racks, telecom |

| HSHI-36SS | 3.6mm | 12mm | SS304 | 110 | Passivated | Petrochemical, cleanroom |

| HSHI-63B | 6.3mm | 25mm | Brass | 112 | Chromate | Military, radar |

| HSHI-55CUG | 5.5mm | 16mm | Copper | 114 | Nickel plate | RF testing |

Honeycomb Waveguide Air Vents—Professional FAQ

Delivery Time, Warranty & Customer Support

- Standard panel production: 10–15 working days; custom projects: 3–4 weeks

- 24 months warranty covering material & process defects (excluding abnormal corrosion or mechanical damage)

- Technical consultation, CAD design assistance, and full logistics tracking provided for all international orders

- All shipments include ISO/MIL-compliant test reports and traceable lot/batch record

Quotation Guidelines for Honeycomb Waveguide Air Vents

- For RFQ, specify: cell size, panel (core) thickness, overall dimension, frame profile, surface finish, and quantity

- Optional: Application environment (indoor/outdoor/extreme), target EMI level, mounting type, gasket requirement

- 3D CAD, DXF, or sample part photos can greatly expedite custom solution quotation

- Large project, strategic OEM and ongoing partnership pricing available

Authoritative Resources & Further Reading

- Electronic Design: Market Trends for EMI Shielding Materials (2023)

- EMC Standards: Waveguide Below Cutoff for Shielding Vents [Forum]

- StackExchange: Technical Discussion of Honeycomb EMI Shielding

- IEEE Xplore: Design and Characterization of Honeycomb EMC Vents (Open Access)

With their modular customization and globally proven compliance, they enable reliable, energy-efficient, and safe operation for the next generation of electronic and electrical infrastructure.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025