- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 09:35

Back to list

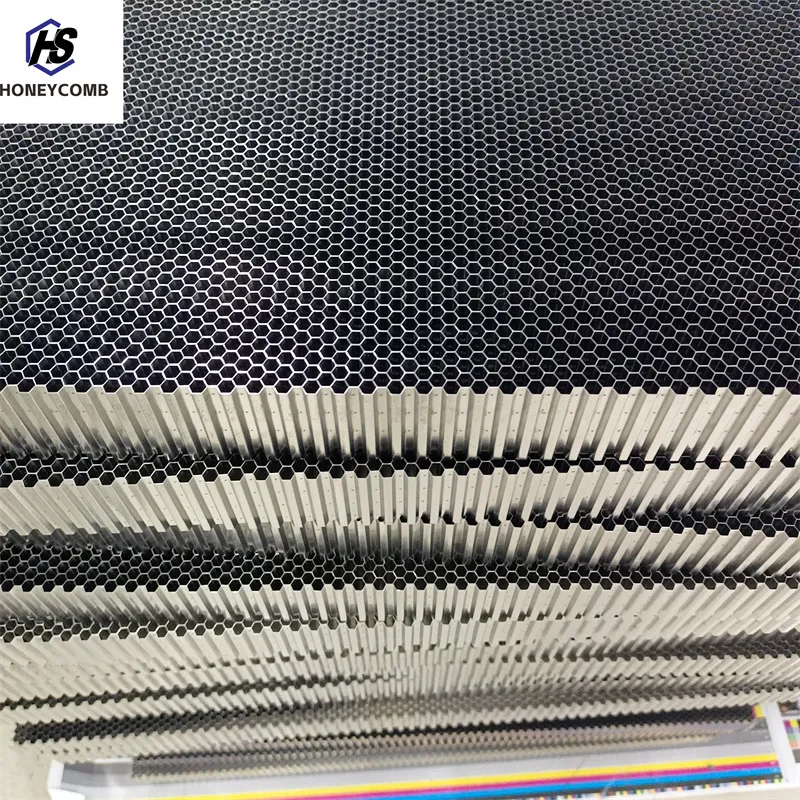

High Shielding Performance 2.0mm Cell Steel Honeycomb Vent For EMI/EMC/RF Shielded

Geperforeerde honingraat kern, known in English as perforated honeycomb core, is an innovative solution primarily used in industries requiring materials that are both lightweight and structurally sound. The unique design mimics a natural honeycomb, with additional perforations that enhance its properties. Here’s a comprehensive look into why this product is revolutionizing its application fields and carrying substantial benefits in numerous sectors.

From a professional standpoint, expertise in manufacturing geperforeerde honingraat kern is crucial. The precision required in crafting the tiny perforations within each cell demands advanced manufacturing technologies and materials science expertise. Such attention to detail ensures that each unit produced can withstand the harshest conditions without compromising its structural advantages. Manufacturers committed to upholding these high standards demonstrate exceptional authoritativeness in their specialization, fostering trust and reliability among clients and stakeholders. Authoritativeness also comes from continued innovation and adherence to stringent quality controls. Manufacturers who invest in state-of-the-art testing facilities not only reassure clients of their commitment to quality but also push the boundaries of what geperforeerde honingraat kern can achieve. By collaborating with research institutions and technology partners, these manufacturers stay ahead in delivering cutting-edge solutions that drive the industry forward. Finally, trustworthiness is paramount in a product meant to bear substantial loads. End-users need confidence that the material performs reliably under pressure and environmental conditions. Companies that openly share their testing methodologies, provide case studies, and engage in transparent customer service practices create a trustworthy bond with their clients. This transparency is a testament to their confidence in their product's capability and longevity. In conclusion, the geperforeerde honingraat kern is not just a product but a technological marvel that finds uses across various heavy-duty industries. It represents exemplary engineering combined with a keen understanding of modern-day industrial challenges. Its unique features not only make operations more efficient but also signify a giant leap towards more sustainable and reliable material technology. The strategic application of this revolutionary material undoubtedly heralds a new era in material sciences, paving the way for future innovations and industrial advancements.

From a professional standpoint, expertise in manufacturing geperforeerde honingraat kern is crucial. The precision required in crafting the tiny perforations within each cell demands advanced manufacturing technologies and materials science expertise. Such attention to detail ensures that each unit produced can withstand the harshest conditions without compromising its structural advantages. Manufacturers committed to upholding these high standards demonstrate exceptional authoritativeness in their specialization, fostering trust and reliability among clients and stakeholders. Authoritativeness also comes from continued innovation and adherence to stringent quality controls. Manufacturers who invest in state-of-the-art testing facilities not only reassure clients of their commitment to quality but also push the boundaries of what geperforeerde honingraat kern can achieve. By collaborating with research institutions and technology partners, these manufacturers stay ahead in delivering cutting-edge solutions that drive the industry forward. Finally, trustworthiness is paramount in a product meant to bear substantial loads. End-users need confidence that the material performs reliably under pressure and environmental conditions. Companies that openly share their testing methodologies, provide case studies, and engage in transparent customer service practices create a trustworthy bond with their clients. This transparency is a testament to their confidence in their product's capability and longevity. In conclusion, the geperforeerde honingraat kern is not just a product but a technological marvel that finds uses across various heavy-duty industries. It represents exemplary engineering combined with a keen understanding of modern-day industrial challenges. Its unique features not only make operations more efficient but also signify a giant leap towards more sustainable and reliable material technology. The strategic application of this revolutionary material undoubtedly heralds a new era in material sciences, paving the way for future innovations and industrial advancements.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025