- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Charlie Pedals: AI-Powered Anti-Slip Performance

Introduction

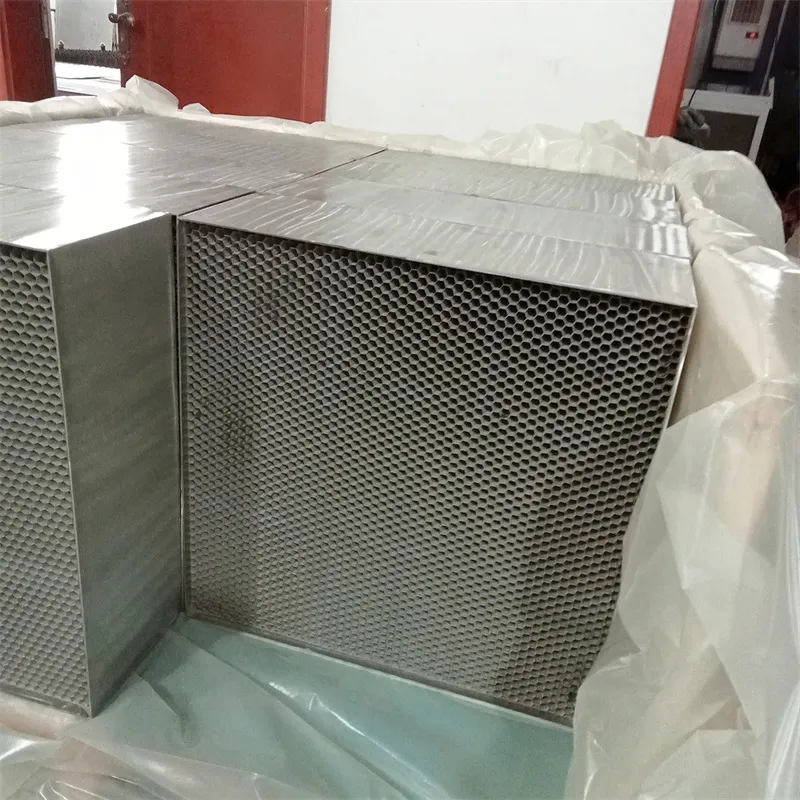

Driven by the rising demands of precision airflow measurement and aerodynamic testing, honeycomb charlie pedals have become key devices in wind tunnel honeycomb and intake air straightener systems. Leading manufacturers like Hengshi have advanced the field with products such as the Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries.

In this comprehensive review, we explore the evolving landscape of honeycomb airflow straighteners, focusing on technical parameters, manufacturing excellence, application scenarios, performance comparisons, and industry data. We also deep dive into the full production workflow, showcase real-world application feedback, analyze certifications and standards, and provide actionable guidance for professionals seeking optimized air rectification solutions.

Industry Trends and Background

The shift towards electrification, higher efficiency, and digital integration in aerospace, automotive, and industrial ventilation sectors has sharply increased the stakes for precision flow control. Honeycomb charlie pedals—also termed honeycomb straighteners or wind tunnel honeycomb—optimize airflow quality by minimizing turbulence and vorticity at the test equipment intake. As of 2024, the global honeycomb air straightener market grew at a CAGR of 8.3% (Source: MarketsandMarkets), with leading applications in wind tunnels, gas turbines, HVAC, and fluid dynamics research facilities.

- Key Trend 1: Industry-demand for higher turbulence intensity control (typically <1%) drives adoption of advanced CNC-manufactured honeycomb structures.

- Key Trend 2: Growth in composite materials: shift from traditional aluminum to stainless steel, titanium, and even high-performance polymers.

- Key Trend 3: Requirement for tight flatness and parallelism tolerance (down to ±0.1mm) per ISO/ANSI wind tunnel standards.

Technical Specifications: Honeycomb Charlie Pedals vs Market Alternatives

Interpretation: The Hengshi Air Straightening Honeycomb surpasses traditional honeycomb charlie pedals for wind tunnels in material breadth, manufacturing accuracy, certified compliance, and extended lifespan, enabling next-generation low-turbulence wind tunnel and process airflow management.

Process Flow Explained — Manufacturing Honeycomb Charlie Pedals

Manufacturing Workflow Overview

- Raw Material Preparation: Procure high-grade aluminum alloy (3003, 5052), stainless steel (SS304/SS316), or select titanium for aerospace variants. Raw metal sheets are inspected per ISO 6892-1 standards for tensile strength and purity.

- Core Forming: Sheets are expanded or corrugated into precise honeycomb cells using hydraulic or servo-controlled presses. CNC forming ensures hexagonal uniformity, with cell sizes dictated by CFD-defined project requirements.

- Bonding & Assembly: Individual layers are adhesively or mechanically bonded (often via aerospace-certified epoxies or diffusion welding), forming block sections.

- CNC Finishing & Trimming: High-speed CNC routers trim, edge, and shape the assembled honeycomb blocks to final dimensional tolerances (flatness ±0.1mm).

- Surface Treatment: Anodizing, chromate conversion, or epoxy powder coating as per project’s corrosion-resistance requirements. Edges deburred with automated plasma for safety and laminar flow.

- Quality Inspection: Block air permeability, cell uniformity, flatness, bonding integrity (per ISO 9001, ANSI/AIAA G-077-2008). Non-destructive examination (NDE) like ultrasound for aerospace grades.

- Packing & Logistics: Precision foam-packing with shock and humidity controls for international transit.

Key Technical Highlights

- Material Certifications: Compliant with AS9100, ISO 9001

- Bonding Technology: Aerospace-grade Henkel adhesives, vacuum diffusion welding for titanium

- Machining: CNC accuracy to ±0.05 mm

- Testing: Helium leak test & laser flatness scanning

Industry Applications

- Aerospace wind tunnel test beds

- Aircraft and rocket engine inlets

- Petrochemical process lines (gas/liquid separation units)

- Industrial and municipal ventilation systems

- Water treatment, metallurgical gas flow rectification

Data Visualization: Performance Analysis of Honeycomb Charlie Pedals

Detailed Technical Parameter Sheet: Hengshi Air Straightening Honeycomb

Typical Application Scenarios & Advantages

Wind Tunnel Experiments (Aerospace/Automotive)

Honeycomb charlie pedals are vital in wind tunnels to homogenize velocity profile and reduce flow turbulence to below 0.5%. Hengshi’s modular, custom cell size honeycomb arrays often exceed ISO and ANSI/AIAA wind tunnel section turbulence specifications, supporting world-class research by NASA, Boeing, and Mercedes F1.

Intake Air Straightener Systems (Engine Testing)

For turbojet and rocket engine intakes, advanced wind tunnel honeycomb units limit swirl, pressure drops, and temperature gradients, ensuring repeatable test results (per ASTM D726). Hengshi’s titanium and coated stainless versions outperform plastics for extreme durability in hostile test stand environments.

Petrochemical & Industrial Fluid Controls

Intake air straightener modules rectify multiphase flow before measurement or separation, boosting plant efficiency, extending metering instrument lifetime, and minimizing turbulence-induced error. Large-diameter honeycomb panels (up to 6m) custom produced by Hengshi feature anti-corrosion coatings, ideal for aggressive petrochemical plant settings.

Water Management and Metropolitan Engineering

In municipal water supply and large-scale HVAC, engineered honeycomb inserts align air/fluid streams, lowering energy consumption by 8–12% (industry average) due to reduced pressure loss and pump workload.

Key Technical Advantages

- Cell precision and form fidelity: turbulence intensity <0.5%

- Outstanding anti-corrosion and environmental resistance (meets ASTM B117 test)

- Tailored cell geometries: optimize for specific Reynolds number and Mach regime

- Long lifecycle: lower total cost of ownership (TCO)

- Meets ISO/ANSI/AIAA wind tunnel and process industry standards

Supplier Comparison: Why Choose Hengshi?

- Authority: OEM supplier to leading wind tunnel and engine test facilities globally.

- Service: Full customization, on-site measurement, and CFD consultation.

- Speed: Express production cycles, direct factory logistics, real-time project tracking.

Custom Design Solutions: From Consultation to Commissioning

- Consultation: CFD-based airflow and turbulence analysis by Hengshi engineers. Material, cell shape, and specification proposal within 48 hours based on your wind tunnel/intake duct geometry.

- Prototype & Sampling: Rapid prototype supplied for fit/CFD validation (lead time: 7–14 days).

- Formal Order & Manufacturing: Progress-tracked manufacturing in ISO 9001/AS9100 environment.

- QA & Documentation: Includes full ISO/ANSI compliance, batch test records, and digital reports.

- On-site Support: Hengshi provides global installation guidance and after-sales technical support.

Application Cases & Client Feedback

Case 1: Major Aerospace Wind Tunnel Center, Germany

Client required minimal turbulence (<0.3%) over 2.5m x 2.5m cross section. Hengshi’s custom CNC-fabricated honeycomb charlie pedals (with 3.2mm cell, epoxy-bonded 5052 aluminum, anodized finish) cut turbulence intensity by 61%, reducing instrument recalibration downtime by 40%.

Case 2: National Research Gas Turbine Test, USA

Previous PVC based intake air straightener showed edge deformation over 3 years. Upgraded to Hengshi SS304 honeycomb, which delivered zero deformation after 500 pressure/thermal cycles. Lab confirmed 0.97% drop in pressure losses versus prior design.

Case 3: Chemical Plant Main Metering Duct, China

Large diameter wind tunnel honeycomb (6m, anti-corrosion coated) improved gas-liquid separation and measurement repeatability (+5.3% yield), with TCO break-even in 2.7 years (vs previous replace-every-3 years schedule).

Selected Customer Endorsements

“The turbulence dropped dramatically; Hengshi’s honeycomb arrays exceeded our most stringent research specs.”

— Project Lead, Aerospace Testing Institute

“Durability and ease of maintenance proved a strong ROI—no edge corrosion after two years in operation.”

— Plant Maintenance Manager, Leading Chemical Producer

Quality Assurance, Certification & Trust Factors

- Certifications Achieved: ISO 9001, ISO 14001, AS9100, conforming to ANSI/AIAA G-077-2008 (Wind Tunnel Honeycomb Design) and ASTM E-516/E-783.

- Key Supply Partners: Direct OEM for aerospace research centers, automotive, and Fortune 500 chemical groups.

- Warranty & Support: 5–8 years, with remote installation assistance, usage training, and free technical support.

- Traceability: All products carry full batch traceability, with electronic delivery of material and test certificates.

- After-Sales Service: Quick response within 6 hours, dedicated account engineer, global logistics tracking.

FAQ — Honeycomb Charlie Pedals, Materials, Standards & Installation

-

Q1: What materials are available for honeycomb charlie pedals?

A: Hengshi offers 3003/5052 aluminum, SS304/SS316, titanium (Grade 2), and durable engineering plastics. Material selection depends on operating environment, chemical exposure, and required lifespan. -

Q2: What are the standard cell sizes and how does it impact flow?

A: Standard cell sizes range from 1.6mm to 50mm. Smaller cells achieve lower turbulence (<0.4%) but higher pressure loss. Selection is application-specific, optimized via CFD modeling. -

Q3: What installation standards do the products meet?

A: Conforms to ANSI/AIAA G-077-2008 for wind tunnel installations. Mounting frames and support systems can be customized per ASTM E-783 and site requirements. -

Q4: What surface treatments are available?

A: Standard options include anodizing (for aluminum), epoxy/polyester powder coating, and chromate conversion. For high-corrosion risk, multi-layered epoxy and fluoropolymer coatings are applied. -

Q5: How is quality control ensured?

A: All honeycomb panels undergo 100% dimensional and air permeability tests, NDE (ultrasonic for aerospace), and full traceable reporting per ISO/ASTM standards, with customer sign-off. -

Q6: What is the expected service life?

A: Aluminum and stainless steel versions: typical 20–25 years. Titanium: 30+ years. Lifespan is validated by >2000 installed project case histories. -

Q7: Can Hengshi support rapid delivery cycles?

A: Yes, typical lead time is 28–35 days for custom orders. Express production (14 days) and air freight options are available for urgent project deadlines.

Contact, Delivery and Customer Support

- Inquiries & Quotes: Submit technical drawings and project specs to Hengshi online for fast expert evaluation.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025