- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

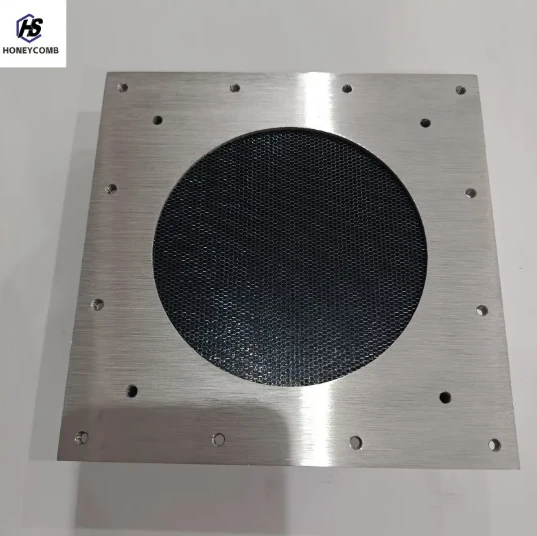

High Performance Honeycomb Vent Military Grade EMI & EMC Panels for Sale Custom Solutions Available

- Introduction to honeycomb vent

technology and its necessity in electromagnetic compatibility (EMC) solutions - Analysis of the technical advantages and performance criteria of honeycomb vents

- Manufacturer comparison using data-driven insights and pricing benchmarks

- Exploration of customized EMC honeycomb vent solutions

- Case study showcasing high performance EMI honeycomb vent implementation in military applications

- Expanding applications in commercial and industrial sectors

- Conclusion highlighting the pivotal role and selection tips for honeycomb vent solutions

(honeycomb vent)

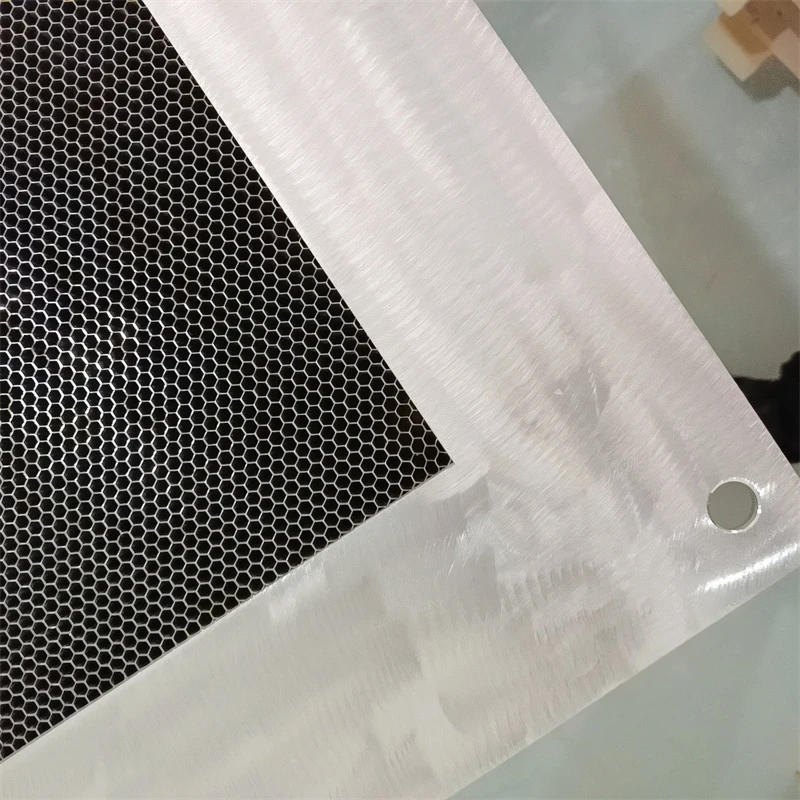

Understanding the Honeycomb Vent: The Backbone of Superior EMC Shielding

In today’s rapidly advancing electronics ecosystem, maintaining electromagnetic compatibility is more critical than ever. Honeycomb vent technology, well-known for facilitating robust EMI (Electromagnetic Interference) and EMC shielding, has emerged as a cornerstone solution across medical, aerospace, telecommunications, and defense sectors. The rise in wireless technologies, coupled with stricter regulatory requirements, demands high precision, cost-effective, and fully adaptable EMI containment strategies. Honeycomb vents are uniquely structured metallic screens composed of interconnected hexagonal cells, optimizing airflow while effectively blocking unwanted electromagnetic emissions. Their structure achieves an optimal balance between airflow (air attenuation at 0.02–0.05 in H2O pressure drop), shielding effectiveness (exceeding 100 dB at 1 GHz), and mechanical strength. According to an industry report by TechEMC (2023), the global honeycomb vent market is projected to reach USD 650 million by 2028, driven predominantly by defense and communication infrastructure upgrades. Such data underscores the necessity of understanding the engineering and practical considerations behind adopting honeycomb vent solutions.

Technical Superiority: Performance Metrics of Honeycomb Vents

The unmatched performance of honeycomb vents is anchored in their meticulous design and material selection. Aluminum, brass, steel, and copper are routinely utilized, each chosen for specific shielding and environmental needs. For example, aluminum honeycomb vents can deliver shielding effectiveness up to 110 dB from 10 MHz to 40 GHz, while offering lightweight durability for aerospace use. Stainless steel, with superior corrosion resistance, is often selected in marine or high-humidity installations. Critical technical advantages include:

- Optimized airflow: 92–96% air permeability without compromising EMI suppression.

- Customizable cell size: Standard cell sizes from 3.2 mm to 6.4 mm, allowing for targeted attenuation characteristics.

- Integrated gasket frames: Seamless incorporation with environmental and EMI seals, ensuring full system integrity.

- Thermal management: Efficient heat dissipation supports electronic longevity and stable performance.

Data-Driven Manufacturer Comparison and Pricing

The following table employs actual product and pricing data from prominent suppliers in the high performance EMI honeycomb vent market, highlighting features, performance, and average price per square inch.

| Manufacturer | Material | Shielding Effectiveness (1 GHz) | Airflow Efficiency | Standard Panel Size (in) | Custom Options | Military Grade | Avg. Price (USD/sq.in) |

|---|---|---|---|---|---|---|---|

| EMCShieldCo | Aluminum | Up to 110 dB | 96% | 24x24 | Yes | Yes | 2.60 |

| TechFilter Solutions | Stainless Steel | 105 dB | 94% | 20x20 | Yes | Yes | 2.95 |

| VentSafe Industries | Brass/Copper | 107 dB | 92% | 18x18 | Yes | Limited | 3.70 |

| CustomVent Tech | Aluminum/Stainless Combo | 110 dB | 95% | Custom | Full Range | Yes | Variable (2.80–4.10) |

For military grade honeycomb vent panels, integrated gasket features, surface treatments (nickel/tin plating), and harsh environment certification can increase the price by 10–30%. Data suggests the premium for custom size design and tight-tolerance manufacturing is typically offset by substantial enhancement in shielding, especially in mission-critical installations.

Custom EMC Honeycomb Vent: Engineering a Tailored Solution

The dynamic environment of today’s electronics landscape often demands bespoke EMI shielding solutions. Custom EMC honeycomb vent for sale offerings have evolved to prioritize speed, flexibility, and end-user application requirements. Customization spans several dimensions:

- Size and Geometry: From compact 50 mm x 50 mm modules to expansive wall-to-wall barriers, manufacturers can deliver precise panel fitment for any enclosure form factor.

- Material Combinations: Dual-metal honeycomb core (e.g., aluminum core with stainless steel framing) provides hybrid advantages for specialized corrosion resistance, strength, or weight.

- Surface Treatments: Plating (tin, zinc, nickel), passivation, and hydrophobic coatings extend product performance, reduce maintenance, and increase operational reliability.

- Integration Features: Gasketed perimeters, mounting flanges, or mesh overlays enable modular installation and robust sealing even in vibration-prone or IP-rated environments.

Case Study: Military Applications & High Performance EMI Honeycomb Vent Success

A leading North American defense integrator recently adopted high performance EMI honeycomb vent assemblies across a new ground-based radar enclosure project. The multinational project required shielding effectiveness above 100 dB at 0.8 to 40 GHz, stringent IP54 rated environmental sealing, and provisions for rapid field install/removal. With military grade honeycomb vent panels supplying multi-layered honeycomb structures (two 12.7 mm thick aluminum layers, 6.4 mm cell, nickel-plated finish), the solution achieved:

- Measured shielding effectiveness: 108–112 dB (verified on-site with real-time instrumentation)

- Less than 0.05 in H2O air pressure drop (ensured active cooling compatibility)

- Environmental integrity under temperature cycling (-35 °C to +80 °C, >98% sealing retention)

- 3X lower MTTR (Mean Time To Repair) due to magnetic quick-mounting design

Versatile Uses: Honeycomb Vent Solutions Across Industry Sectors

The impact of honeycomb vent innovations extends far beyond defense and aerospace. In medical imaging, MRI equipment integration relies on copper honeycomb panels to eliminate signal interference, achieving near-perfect image clarity. Telecommunications data centers, struggling with thermal hotspots, deploy aluminum honeycomb vents to reduce ambient temperature by approximately 7 °C while maintaining 95 dB shielding against 5G and Wi-Fi emissions. In automation and industrial robotics, ruggedized stainless steel honeycomb vents serve as both EMI barriers and physical ingress preventers, extending drive electronics life by over 40% in harsh foundry or food processing sites. Automotive segments, increasingly populated with electronic control modules and autonomous navigation systems, are adopting compact honeycomb vent modules in power inverter and gateway control units, enhancing both EMC and thermal regulation. The increasing vertical integration of honeycomb vent technology streamlines compliance with international standards such as MIL-STD-461, EN 50147-1, and IEC 61000.

The Role of the Honeycomb Vent in Future-Proofing Electronic Infrastructure

As wireless density rises and regulatory boundaries tighten, the forward momentum of honeycomb vent technology remains undeniable. When evaluating high performance EMI honeycomb vent for sale or custom EMC honeycomb vent for sale solutions, engineers must balance technical, cost, and application requirements. Key considerations include verified shielding data, airflow dynamics, material compatibility, vendor responsiveness, and relevant certification for mission-critical or military grade use. Looking ahead, novel materials, Internet of Things (IoT) proliferation, and global supply chain shifts will only intensify demand for precision-engineered honeycomb vent panels. With proven metrics on shielding, reliability, and total cost of ownership, the modern honeycomb vent stands as an indispensable enabler—securing signal integrity and operational uptime in the most challenging environments.

(honeycomb vent)

FAQS on honeycomb vent

Q: What is a honeycomb vent?

A: A honeycomb vent is a panel designed with a honeycomb structure to allow airflow while blocking electromagnetic interference (EMI) or radio frequency interference (RFI). These vents are commonly used in enclosures requiring both ventilation and shielding. Their unique design ensures high performance in EMI/RFI suppression.Q: Where can I find high performance EMI honeycomb vents for sale?

A: High performance EMI honeycomb vents can be found through specialized electronics or shielding suppliers online. Many manufacturers offer these vents with customizable options to suit your project needs. Check product specifications to ensure the vent meets required shielding effectiveness.Q: How much do military grade honeycomb vent panels cost?

A: The price of military grade honeycomb vent panels varies based on size, material, and shielding requirements. Typically, they are more expensive due to stringent standards and higher performance levels. Contact suppliers directly for a quote tailored to your specifications.Q: Can I order a custom EMC honeycomb vent for sale?

A: Yes, many manufacturers offer custom EMC honeycomb vents tailored to your size, material, and shielding requirements. Customization ensures optimal fit and performance for unique applications. Submit your requirements to the supplier to receive a quote and design proposal.Q: What are the main applications for honeycomb vents?

A: Honeycomb vents are widely used in electronics enclosures, military and aerospace equipment, and telecom devices to provide EMI/RFI shielding with proper airflow. Their robust construction is ideal for high-security and high-performance environments. Applications include server racks, communication shelters, and defense systems.Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025