- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 03:33

Back to list

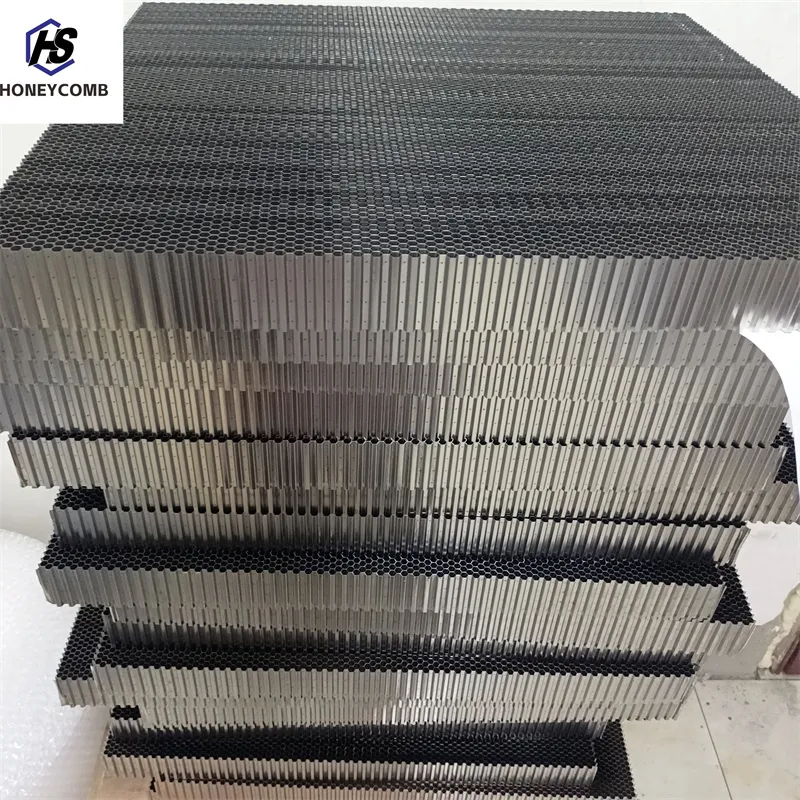

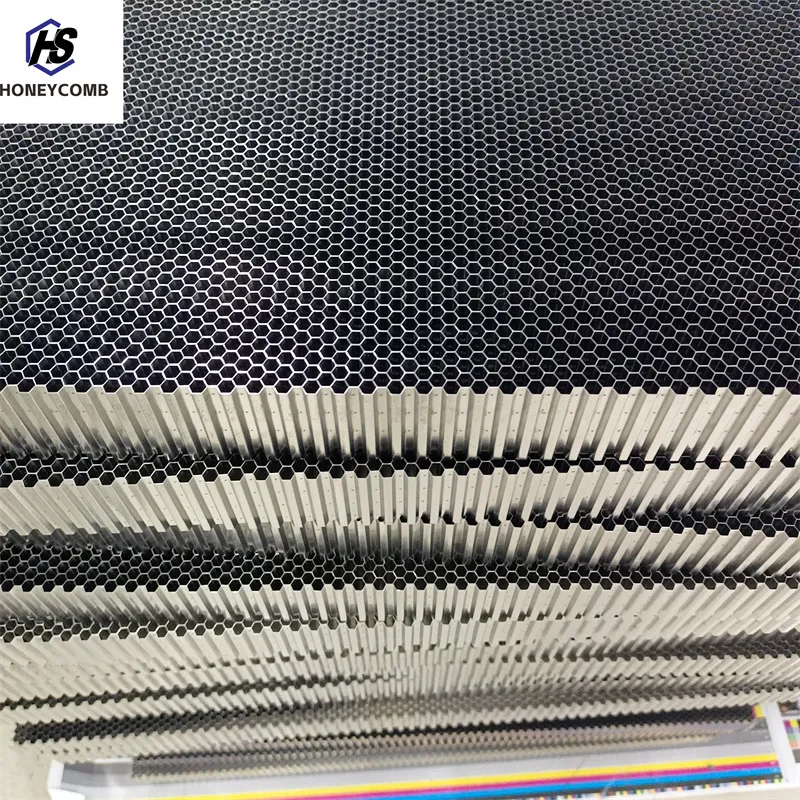

honeycomb core steel door

Unlocking the potential of honeycomb core materials is reshaping industries across the globe. Used extensively for their lightweight and high-strength properties, these materials are becoming crucial in numerous applications ranging from aerospace to construction. Their unique structure, mimicking the natural honeycomb, provides a compelling mix of strength-to-weight ratio, thermal insulation, and durability, offering transformative capabilities that industries can leverage.

Product developers face increasingly diverse and challenging requirements, and honeycomb core materials offer flexible solutions that meet these needs. Versatile by design, they are easily customizable for specific applications. This adaptability can be seen in their use in renewable energy solutions like wind turbine blades, where they provide the necessary balance of weight and strength required to optimize energy output. Moreover, sustainability counts in modern manufacturing. Honeycomb core materials, especially those made from recyclable aluminum, align with the sustainability goals of many industries. As companies push for greener initiatives, using recyclable materials helps reduce the environmental footprint while maintaining high performance. Thus, honeycomb materials not only improve efficiency and durability but also contribute to an organization's sustainability certification efforts. These scientific advancements in the production and application of honeycomb core materials are supported by ongoing research and innovation. Scientists and engineers continue to explore advanced composites that further enhance their performance. Research into bio-inspired designs and automation in production might soon lead to the next generation of honeycomb materials, pushing the boundaries of what’s possible in engineering and design. Private sector investment in the development of innovative honeycomb materials underscores their importance in modern technology. Companies are leveraging these materials to create more advanced products, from consumer goods to large-scale industrial machines. As innovation continues, the partnerships between research institutions and industry leaders will likely spur new applications that we haven’t yet imagined. In conclusion, honeycomb core materials symbolize a fusion of nature-inspired design and high-tech innovation. Their unique properties make them indispensable in a world striving for efficiency, sustainability, and performance. With their broad application spectrum, from everyday consumer products to advanced aerospace engineering, they continue to revolutionize industries and set new standards in material performance.

Product developers face increasingly diverse and challenging requirements, and honeycomb core materials offer flexible solutions that meet these needs. Versatile by design, they are easily customizable for specific applications. This adaptability can be seen in their use in renewable energy solutions like wind turbine blades, where they provide the necessary balance of weight and strength required to optimize energy output. Moreover, sustainability counts in modern manufacturing. Honeycomb core materials, especially those made from recyclable aluminum, align with the sustainability goals of many industries. As companies push for greener initiatives, using recyclable materials helps reduce the environmental footprint while maintaining high performance. Thus, honeycomb materials not only improve efficiency and durability but also contribute to an organization's sustainability certification efforts. These scientific advancements in the production and application of honeycomb core materials are supported by ongoing research and innovation. Scientists and engineers continue to explore advanced composites that further enhance their performance. Research into bio-inspired designs and automation in production might soon lead to the next generation of honeycomb materials, pushing the boundaries of what’s possible in engineering and design. Private sector investment in the development of innovative honeycomb materials underscores their importance in modern technology. Companies are leveraging these materials to create more advanced products, from consumer goods to large-scale industrial machines. As innovation continues, the partnerships between research institutions and industry leaders will likely spur new applications that we haven’t yet imagined. In conclusion, honeycomb core materials symbolize a fusion of nature-inspired design and high-tech innovation. Their unique properties make them indispensable in a world striving for efficiency, sustainability, and performance. With their broad application spectrum, from everyday consumer products to advanced aerospace engineering, they continue to revolutionize industries and set new standards in material performance.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025