- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 17:23

Back to list

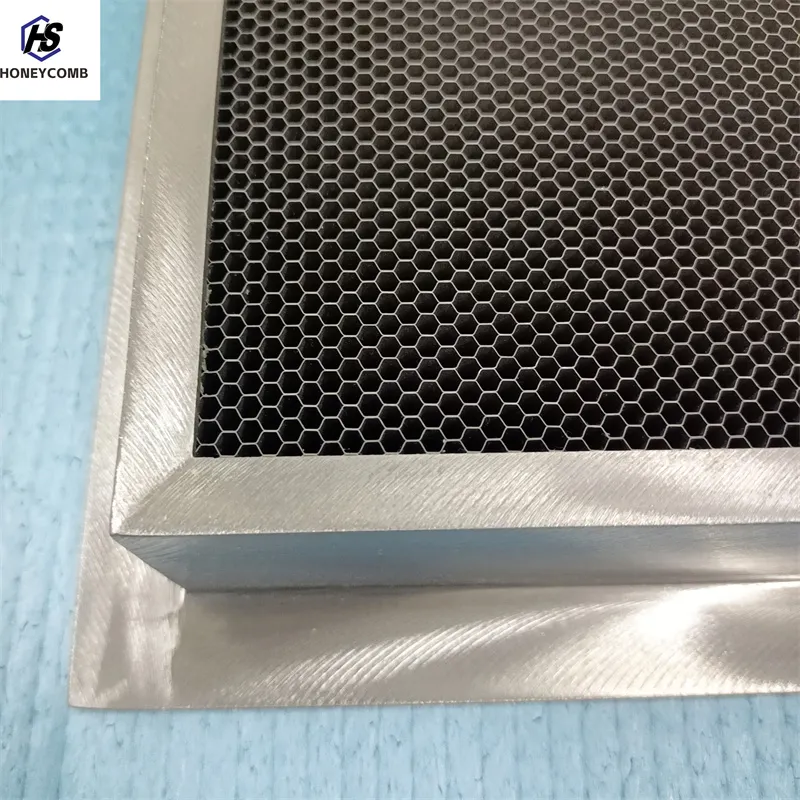

wind tunnel honeycomb

Exploring the Craftsmanship Behind Honeycomb Structures in Wind Tunnels

In wind tunnel applications, the uniqueness of each honeycomb panel cannot be understated. Customization is key, as each tunnel and testing scenario may require different cell sizes and thicknesses. Engineers deploy their proficiency in fluid dynamics and material science to determine the optimal configuration—balancing weight, durability, and aerodynamic performance. This expert customization enhances the wind tunnel's ability to yield high-fidelity results that are crucial for the development of aircraft, automobiles, and various other products reliant on aerodynamics. The authoritative role of honeycomb structures in wind tunnels extends to their impact on industry regulations and standards. Industry leaders often adopt these trustworthy solutions as benchmarks in design and testing processes. Renowned institutions and corporations entrust their most critical aerodynamic assessments to facilities equipped with honeycomb structures, accentuating the reliability and authority of these components within the sector. Trustworthiness is derived from years of research and consistent results. Honeycomb structures have been integral to breakthroughs in aerospace and automotive engineering, cementing their place as essential tools for aerodynamic testing. The continued reliance on these structures highlights their role in past achievements while supporting their necessity in future innovations. In summary, honeycomb structures in wind tunnels are more than just a simple configuration of hexagonal cells; they represent a pinnacle of engineering prowess and accumulated knowledge. They exemplify a harmonization of Experience, Expertise, Authoritativeness, and Trustworthiness—serving as a prime example of how meticulous design and strategic implementation can lead to outstanding results. For engineers, researchers, and industry leaders, these structures are indispensable, continuing to shape the future of aerodynamic advancements in a wide array of industries.

In wind tunnel applications, the uniqueness of each honeycomb panel cannot be understated. Customization is key, as each tunnel and testing scenario may require different cell sizes and thicknesses. Engineers deploy their proficiency in fluid dynamics and material science to determine the optimal configuration—balancing weight, durability, and aerodynamic performance. This expert customization enhances the wind tunnel's ability to yield high-fidelity results that are crucial for the development of aircraft, automobiles, and various other products reliant on aerodynamics. The authoritative role of honeycomb structures in wind tunnels extends to their impact on industry regulations and standards. Industry leaders often adopt these trustworthy solutions as benchmarks in design and testing processes. Renowned institutions and corporations entrust their most critical aerodynamic assessments to facilities equipped with honeycomb structures, accentuating the reliability and authority of these components within the sector. Trustworthiness is derived from years of research and consistent results. Honeycomb structures have been integral to breakthroughs in aerospace and automotive engineering, cementing their place as essential tools for aerodynamic testing. The continued reliance on these structures highlights their role in past achievements while supporting their necessity in future innovations. In summary, honeycomb structures in wind tunnels are more than just a simple configuration of hexagonal cells; they represent a pinnacle of engineering prowess and accumulated knowledge. They exemplify a harmonization of Experience, Expertise, Authoritativeness, and Trustworthiness—serving as a prime example of how meticulous design and strategic implementation can lead to outstanding results. For engineers, researchers, and industry leaders, these structures are indispensable, continuing to shape the future of aerodynamic advancements in a wide array of industries.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025