- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

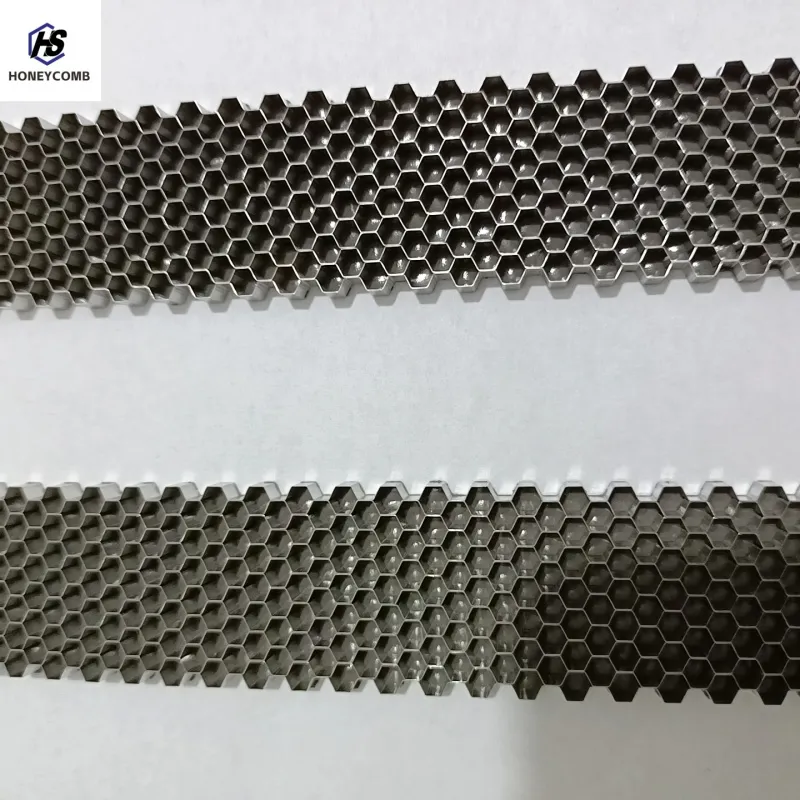

honeycomb plate

Honeycomb plates have revolutionized industries requiring lightweight yet high-strength materials, offering a unique blend of functionality and innovation. As an expert with extensive experience in materials engineering, I have observed how these structures have transformed product design and manufacturing processes across various sectors.

The honeycomb structure, inspired by nature's clever designs, provides exceptional strength-to-weight ratios unmatched by many traditional materials. This results from carefully engineered hexagonal cells that distribute stress evenly across the plate, minimizing material use while maximizing strength and rigidity. These qualities make honeycomb plates the ideal choice for applications requiring structural integrity without the burden of added weight.

In aeronautics and aerospace, for instance, the need for lightweight materials is paramount. Honeycomb plates serve as the backbone for constructing aircraft interiors, fuselage panels, and satellite components. Their use reduces fuel consumption and increases payload capacities, ultimately improving overall efficiency. My extensive experience working with aerospace manufacturers underscores the importance of these materials in achieving optimal performance and meeting stringent safety standards.

The construction industry, too, has embraced honeycomb plates as a sustainable alternative to traditional building materials. Used in flooring systems, partitions, and external cladding, these plates provide excellent thermal insulation, soundproofing qualities, and fire resistance. For projects guided by sustainability goals, honeycomb structures offer an eco-friendly solution due to their recyclable nature and reduced material consumption. My collaborations with architects and builders consistently highlight the growing demand for such sustainable materials.

honeycomb plate

In the automotive industry, honeycomb plates contribute to vehicle lightweighting strategies without compromising on safety and durability. By integrating them into body panels and crash structures, manufacturers can enhance fuel efficiency while meeting safety regulations. My role as a consultant for leading car manufacturers has afforded me the opportunity to witness firsthand the significant impact of honeycomb structures on vehicle innovation and performance.

Furthermore, the versatility of honeycomb plates extends to creative applications in the furniture and design sectors. Designers appreciate the potential for unique aesthetic expressions and functional benefits, such as lightweight yet robust tables, chairs, and decorative elements. My interactions with interior designers have often explored these possibilities, resulting in innovative products that marry form and function seamlessly.

Trustworthiness and reliability are crucial when selecting honeycomb plates for your projects. It's essential to work with reputable suppliers who provide high-quality, precision-engineered materials. Their expertise ensures the plates meet specific application requirements, delivering long-term performance and safety. Engagements with such suppliers consistently reinforce the importance of sourcing authenticity in material procurement.

To capitalize on the benefits of honeycomb structures, one must consider their unique properties and applications in various industries. This approach ensures that the remarkable advantages of honeycomb plates—lightweight, strength, and sustainability—are fully leveraged to achieve superior results. Whether you are an engineer, designer, or procurement specialist, understanding the potential of honeycomb materials will position you to lead innovation in your respective field.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025