- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 06:16

Back to list

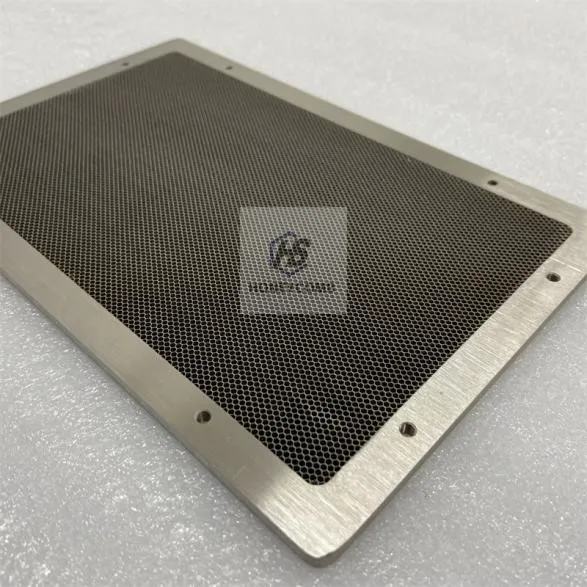

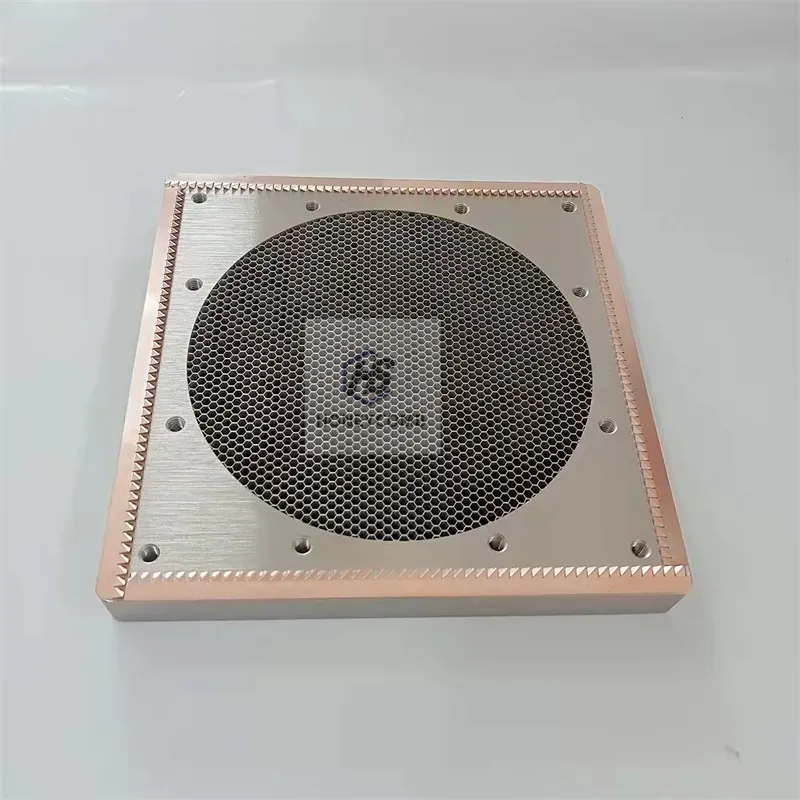

maf honeycomb screen

The innovative design and unparalleled efficiency of honeycomb sandwich panels have made them a cornerstone in modern engineering and architecture. These panels, known for their lightweight and high-strength properties, embody engineering brilliance that sets them apart from traditional materials. Born from nature's ingenuity, the honeycomb structure offers a unique combination of characteristics that deliver exceptional performance across various applications.

From a maintenance perspective, honeycomb sandwich panels offer long-term reliability and durability, outperforming many conventional materials. Their resistance to environmental factors such as moisture and UV radiation ensures longevity, thus reducing the frequency and cost of repairs and replacements. This attribute is especially advantageous in remote or inaccessible locations where ongoing maintenance can pose significant challenges. In the realm of safety, honeycomb sandwich panels again demonstrate their superiority. In addition to outstanding impact resistance, certain configurations of these panels possess inherent fire-retardant properties, safeguarding infrastructure and human life. This safety margin is crucial in applications like public transportation and high-occupancy buildings. Companies specializing in honeycomb technology are continually advancing their expertise, pushing the boundaries of what these panels can achieve. The ongoing research and development mean that honeycomb sandwich panels are constantly evolving, integrating cutting-edge advancements in materials science to deliver even higher performance standards. In summary, the honeycomb sandwich panel is a testament to modern manufacturing excellence, offering a suite of benefits that include unmatched strength-to-weight ratios, thermal and acoustic efficiency, and adaptability across diverse industries. Their role in shaping a more resilient and sustainable future is evident, as they provide a reliable solution that meets the demands of contemporary engineering and architectural projects. Whether for enhancing aviation safety or elevating building sustainability, honeycomb sandwich panels remain at the forefront, embodying the principles of innovation and reliability. As more industries recognize their potential, the trajectory of honeycomb sandwich panels is poised for remarkable growth.

From a maintenance perspective, honeycomb sandwich panels offer long-term reliability and durability, outperforming many conventional materials. Their resistance to environmental factors such as moisture and UV radiation ensures longevity, thus reducing the frequency and cost of repairs and replacements. This attribute is especially advantageous in remote or inaccessible locations where ongoing maintenance can pose significant challenges. In the realm of safety, honeycomb sandwich panels again demonstrate their superiority. In addition to outstanding impact resistance, certain configurations of these panels possess inherent fire-retardant properties, safeguarding infrastructure and human life. This safety margin is crucial in applications like public transportation and high-occupancy buildings. Companies specializing in honeycomb technology are continually advancing their expertise, pushing the boundaries of what these panels can achieve. The ongoing research and development mean that honeycomb sandwich panels are constantly evolving, integrating cutting-edge advancements in materials science to deliver even higher performance standards. In summary, the honeycomb sandwich panel is a testament to modern manufacturing excellence, offering a suite of benefits that include unmatched strength-to-weight ratios, thermal and acoustic efficiency, and adaptability across diverse industries. Their role in shaping a more resilient and sustainable future is evident, as they provide a reliable solution that meets the demands of contemporary engineering and architectural projects. Whether for enhancing aviation safety or elevating building sustainability, honeycomb sandwich panels remain at the forefront, embodying the principles of innovation and reliability. As more industries recognize their potential, the trajectory of honeycomb sandwich panels is poised for remarkable growth.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025