- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 10:06

Back to list

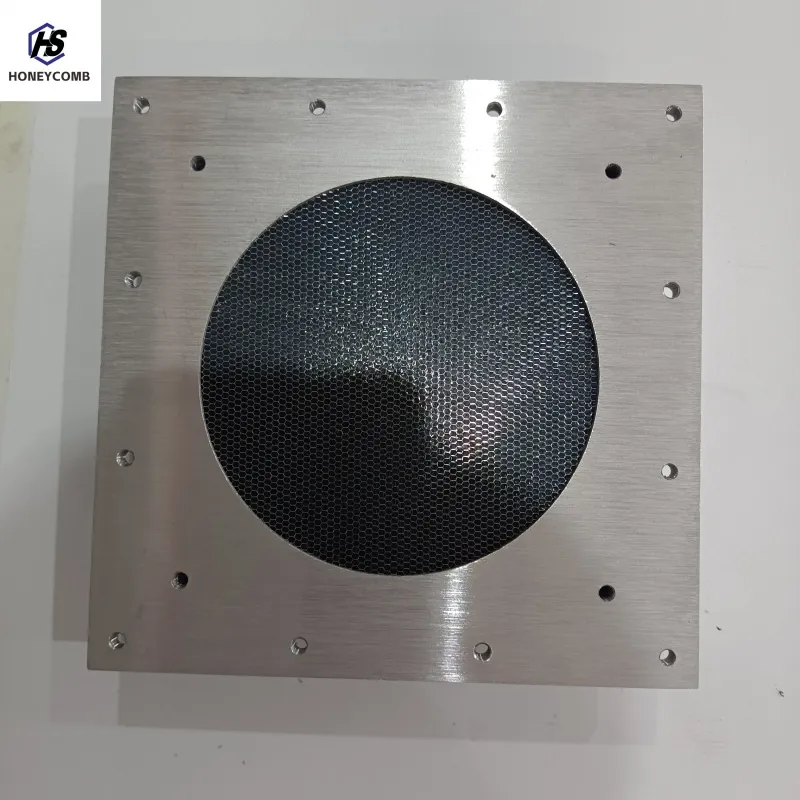

honeycomb seal

The advancements in gas turbine technology have continually revolutionized industries that depend on high efficiency and reliability, and a key innovation in this sphere is the honeycomb seal. Designed to enhance turbine performance and minimize energy loss, honeycomb seals serve as an essential component in a gas turbine’s arsenal. This article delves into the unique advantages, technical intricacies, and real-world applications of honeycomb seals in gas turbines, while emphasizing the expertise, authority, and trustworthiness that manufacturers bring to the table.

Manufacturers assert their authority and trustworthiness in this field through rigorous testing and adherence to industry standards. Honeycomb seals undergo extensive quality assurance processes, such as thermal cycling, pressure testing, and endurance assessments, to certify their reliability and longevity. Leading manufacturers often collaborate with turbine OEMs (Original Equipment Manufacturers) for tailored solutions that enhance the life cycle of the turbine components, offering support and guidance during the integration process. The trustworthiness of honeycomb seals in gas turbines is further cemented by their proven track record in various industries, including power generation, aerospace, and oil and gas. Real-world applications highlight their ability to extend maintenance intervals and reduce downtime, significantly benefiting industries that prioritize operational continuity and efficiency. Case studies often reveal that the transition to honeycomb seals has led to measurable improvements in turbine performance and a tangible reduction in total costs of ownership. In the evolving world of energy and propulsion technologies, honeycomb seals continue to stand out as a product of exceptional value and reliability. Industry leaders who manufacture these seals emphasize a commitment to innovation and sustainability, recognizing the role these components play in creating cleaner, more efficient energy solutions. By continuously refining their design and manufacturing processes, they are setting new standards for performance and dependability in gas turbine technology. Overall, the role of honeycomb seals in gas turbines exemplifies engineering excellence and innovation. Their unique design and superior performance characteristics are supported by the expertise, authority, and trust that industry leaders bring to the table. Through ongoing research and collaboration, these seals are poised to remain at the forefront of gas turbine technology, driving advancements and efficiency in numerous critical applications around the world.

Manufacturers assert their authority and trustworthiness in this field through rigorous testing and adherence to industry standards. Honeycomb seals undergo extensive quality assurance processes, such as thermal cycling, pressure testing, and endurance assessments, to certify their reliability and longevity. Leading manufacturers often collaborate with turbine OEMs (Original Equipment Manufacturers) for tailored solutions that enhance the life cycle of the turbine components, offering support and guidance during the integration process. The trustworthiness of honeycomb seals in gas turbines is further cemented by their proven track record in various industries, including power generation, aerospace, and oil and gas. Real-world applications highlight their ability to extend maintenance intervals and reduce downtime, significantly benefiting industries that prioritize operational continuity and efficiency. Case studies often reveal that the transition to honeycomb seals has led to measurable improvements in turbine performance and a tangible reduction in total costs of ownership. In the evolving world of energy and propulsion technologies, honeycomb seals continue to stand out as a product of exceptional value and reliability. Industry leaders who manufacture these seals emphasize a commitment to innovation and sustainability, recognizing the role these components play in creating cleaner, more efficient energy solutions. By continuously refining their design and manufacturing processes, they are setting new standards for performance and dependability in gas turbine technology. Overall, the role of honeycomb seals in gas turbines exemplifies engineering excellence and innovation. Their unique design and superior performance characteristics are supported by the expertise, authority, and trust that industry leaders bring to the table. Through ongoing research and collaboration, these seals are poised to remain at the forefront of gas turbine technology, driving advancements and efficiency in numerous critical applications around the world.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025