- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 09:34

Back to list

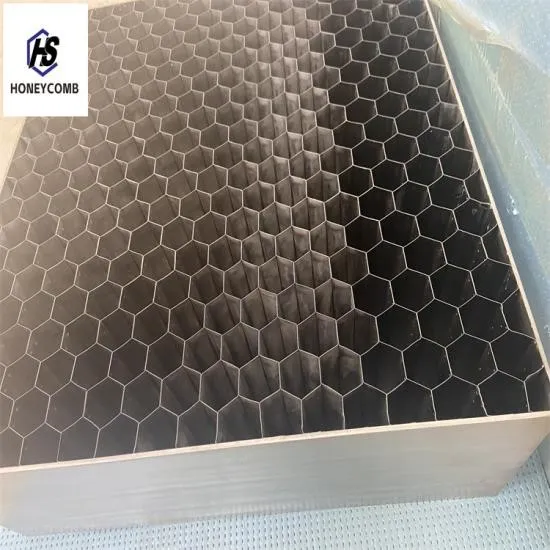

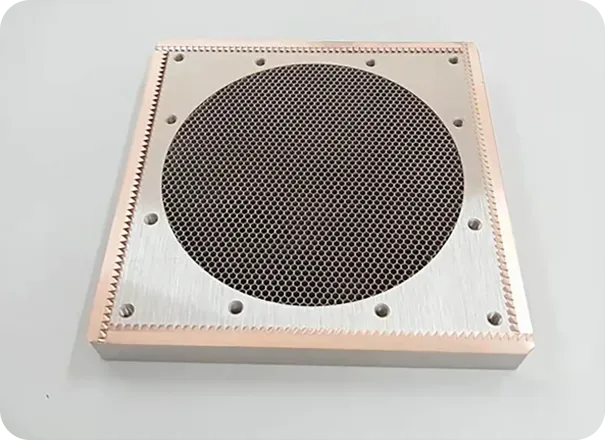

honeycomb vent

In the realm of advanced materials, ITO-conductive glass has carved out a significant niche due to its exceptional properties and diverse applications. As a central component in various technological innovations, understanding the practical uses and advantages of ITO glass can significantly aid manufacturers, engineers, and decision-makers looking to optimize their product designs.

Authoritativeness The longstanding use of ITO glass in major industries underscores its reliability and performance capabilities. Research institutions and industry veterans often reference the versatility of ITO glass, citing its recurrent application in experimental physics, particularly in studies related to optoelectronic devices. Publications in leading scientific journals frequently document advancements in ITO technology, further validating its importance and efficacy in modern electronics. Trustworthiness Quality assurance for ITO-conductive glass is paramount, with manufacturers adhering to strict international standards to ensure consistency and performance. Moreover, trusted suppliers provide detailed specifications and performance metrics, offering customers confidence in their purchase decisions. Customer reviews highlight durability and robustness as key factors for satisfaction, signaling the material's ability to perform under varying environmental conditions without degradation. In conclusion, ITO-conductive glass stands as a paragon of modern material science, bridging the gap between functionality and innovation. For companies keen on integrating this glass into their products, the potential benefits are immense. With a proven track record of enhancing product capabilities and maintaining user satisfaction, ITO glass offers a pathway to revolutionizing how products interact with their users. Embracing this technology not only positions a company at the forefront of innovation but also guarantees a product that meets the ever-evolving demands of today's high-tech world.

Authoritativeness The longstanding use of ITO glass in major industries underscores its reliability and performance capabilities. Research institutions and industry veterans often reference the versatility of ITO glass, citing its recurrent application in experimental physics, particularly in studies related to optoelectronic devices. Publications in leading scientific journals frequently document advancements in ITO technology, further validating its importance and efficacy in modern electronics. Trustworthiness Quality assurance for ITO-conductive glass is paramount, with manufacturers adhering to strict international standards to ensure consistency and performance. Moreover, trusted suppliers provide detailed specifications and performance metrics, offering customers confidence in their purchase decisions. Customer reviews highlight durability and robustness as key factors for satisfaction, signaling the material's ability to perform under varying environmental conditions without degradation. In conclusion, ITO-conductive glass stands as a paragon of modern material science, bridging the gap between functionality and innovation. For companies keen on integrating this glass into their products, the potential benefits are immense. With a proven track record of enhancing product capabilities and maintaining user satisfaction, ITO glass offers a pathway to revolutionizing how products interact with their users. Embracing this technology not only positions a company at the forefront of innovation but also guarantees a product that meets the ever-evolving demands of today's high-tech world.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025