- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 24, 2025 00:36

Back to list

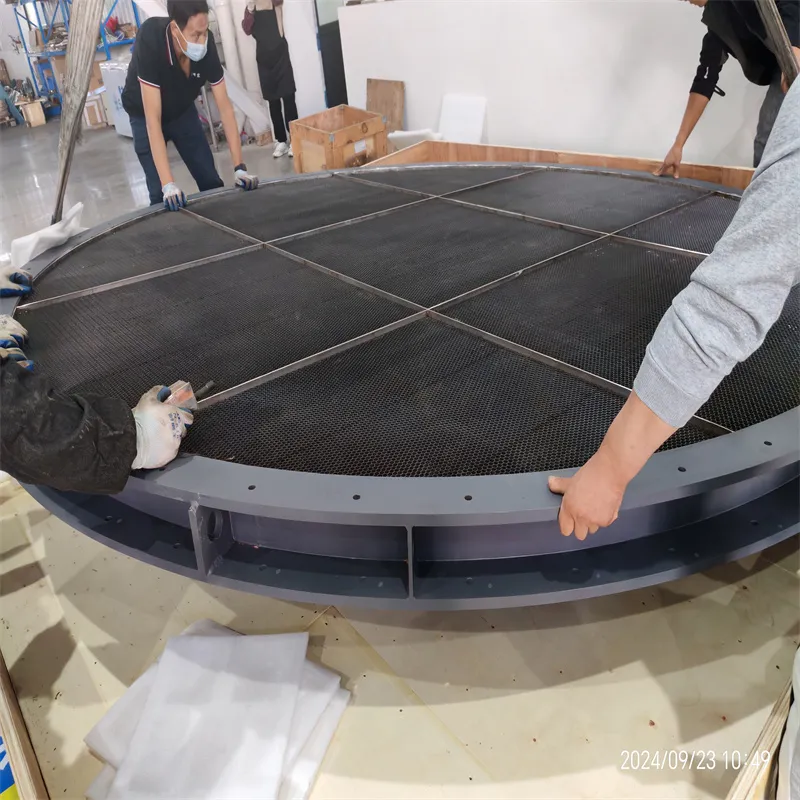

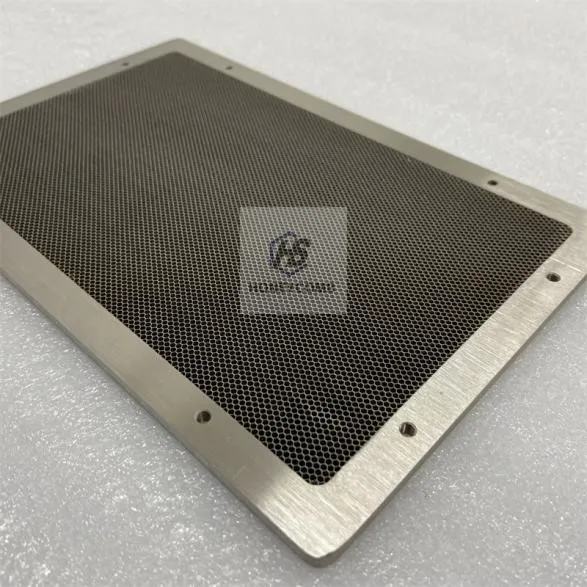

honeycomb ventilation panels

Honeycomb ventilation panels have revolutionized the way we approach ventilation solutions in modern architecture and engineering. These panels are not merely a product of innovative design but stand as a testament to expert engineering and sustainable practices. The unique structure of honeycomb panels provides several distinct advantages that make them incredibly appealing for various applications ranging from industrial to residential spaces.

Moreover, honeycomb ventilation panels contribute significantly to sustainable building practices. Their manufacturing process typically involves materials that are recyclable and environmentally friendly, aligning with global efforts to reduce carbon footprints and promote green building initiatives. Professionals advocating for sustainability emphasize the importance of such materials in achieving energy-efficient and eco-friendly designs. Authoritative voices in the field of architectural design have endorsed honeycomb ventilation panels as a forward-thinking solution. Their application is backed by rigorous testing and compliance with industry standards, ensuring they meet the highest safety and efficacy requirements. In sectors where air quality and ventilation are crucial, such as in hospitals and laboratories, the trust placed in these panels is validated by their routine use and proven results. Trustworthiness in the selection of ventilation solutions can make a significant difference in project outcomes. Clients and stakeholders are increasingly aware of the implications of energy inefficiency and poor air quality. Honeycomb ventilation panels provide not only peace of mind but also evidence-based benefits that are communicated transparently through product documentation and case studies. This transparency is vital in building a strong relationship between manufacturers, designers, and end-users, fostering a collaborative approach towards sustainable development. In closing, selecting honeycomb ventilation panels signifies a commitment to quality, efficiency, and responsibility. Their incorporation into projects reflects expertise that values not only immediate functional needs but also long-term economic and environmental considerations. As the demand for sophisticated and sustainable ventilation solutions grows, these panels stand out as a pinnacle of industry innovation and practical application.

Moreover, honeycomb ventilation panels contribute significantly to sustainable building practices. Their manufacturing process typically involves materials that are recyclable and environmentally friendly, aligning with global efforts to reduce carbon footprints and promote green building initiatives. Professionals advocating for sustainability emphasize the importance of such materials in achieving energy-efficient and eco-friendly designs. Authoritative voices in the field of architectural design have endorsed honeycomb ventilation panels as a forward-thinking solution. Their application is backed by rigorous testing and compliance with industry standards, ensuring they meet the highest safety and efficacy requirements. In sectors where air quality and ventilation are crucial, such as in hospitals and laboratories, the trust placed in these panels is validated by their routine use and proven results. Trustworthiness in the selection of ventilation solutions can make a significant difference in project outcomes. Clients and stakeholders are increasingly aware of the implications of energy inefficiency and poor air quality. Honeycomb ventilation panels provide not only peace of mind but also evidence-based benefits that are communicated transparently through product documentation and case studies. This transparency is vital in building a strong relationship between manufacturers, designers, and end-users, fostering a collaborative approach towards sustainable development. In closing, selecting honeycomb ventilation panels signifies a commitment to quality, efficiency, and responsibility. Their incorporation into projects reflects expertise that values not only immediate functional needs but also long-term economic and environmental considerations. As the demand for sophisticated and sustainable ventilation solutions grows, these panels stand out as a pinnacle of industry innovation and practical application.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025