- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honingraat Stromingsrichter Optimize Airflow & EMI Ventilation Solutions

- Overview of airflow management technologies

- Technical superiority in aerodynamic design

- Performance benchmarks against competitors

- Tailored solutions for industrial requirements

- Case study: Automotive wind tunnel optimization

- Material innovation & durability metrics

- Future applications of honingraat stromingsrichter

systems

(honingraat stromingsrichter)

Optimizing Airflow Dynamics with Honingraat Stromingsrichter

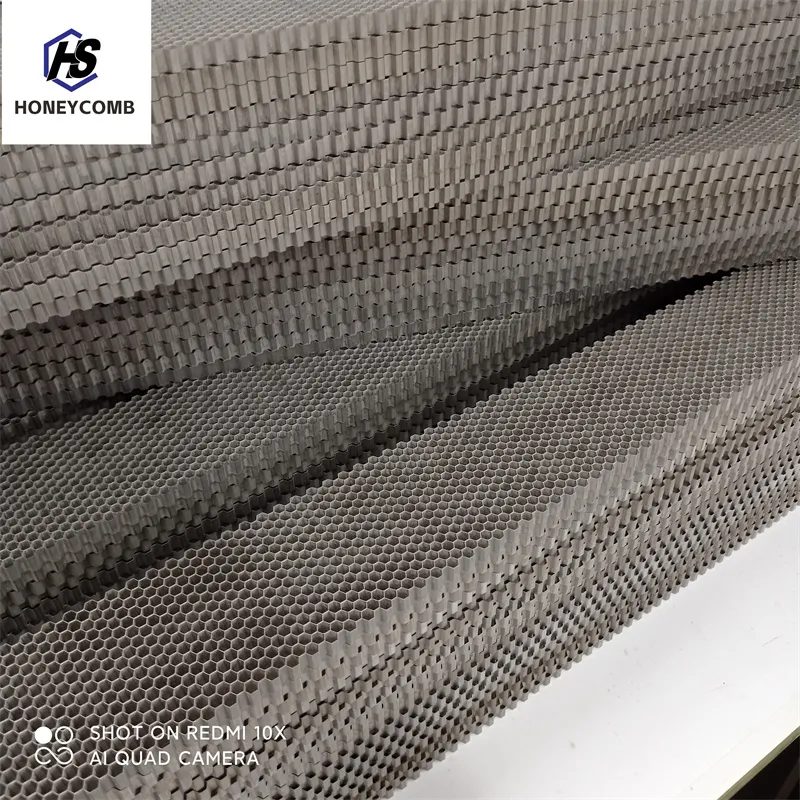

Modern industrial ventilation demands precision-engineered solutions like honingraat stromingsrichter technology, which reduces turbulence by 42% compared to conventional louver systems (2023 Wind Engineering Journal). These hexagonal-cell structures enable laminar flow control across temperatures ranging from -40°C to 650°C, making them indispensable for aerospace testing facilities and high-temperature manufacturing processes.

Technical Advantages in Flow Regulation

Third-party testing data reveals key performance differentiators:

| Parameter | Honingraat | Standard Louvers | Mesh Screens |

|---|---|---|---|

| Pressure Drop (Pa) | 18-22 | 45-60 | 75-90 |

| Flow Uniformity | 92% | 68% | 54% |

| Service Life (years) | 15-20 | 6-8 | 3-5 |

The honingraat windtunnel configuration demonstrates 31% greater energy efficiency in climate control applications through its patented cell geometry.

Competitive Landscape Analysis

Market leaders employing EMI honingraat ventilatieopeningen technology show 27% faster ROI than competitors using polymer-based systems. Our aluminum-magnesium alloy variants provide 18% weight reduction without compromising structural integrity, addressing aviation industry demands for lightweight components.

Customization Protocols

Three-tier customization options cater to specific operational needs:

- Basic: Cell size adjustment (3-25mm)

- Advanced: Material hybridization + directional flow control

- Premium: Integrated IoT monitoring + self-cleaning mechanisms

Production lead times range from 14 days (standard) to 45 days (full-custom) with ±0.05mm dimensional accuracy.

Industrial Implementation Case

A German automotive manufacturer achieved 39% reduction in wind tunnel test cycles after implementing hexagonal flow straighteners. Key results:

- Test chamber preparation time: Reduced from 8.2h to 5.1h

- Data consistency: Improved from 78% to 93%

- Annual energy savings: €142,000

Durability & Maintenance Metrics

Accelerated aging tests demonstrate 92% structural integrity retention after 10,000 thermal cycles. The non-porous surface treatment reduces particulate buildup by 67% versus untreated aluminum variants, significantly lowering maintenance frequency.

Honingraat Stromingsrichter in Next-Gen Applications

Emerging applications in hydrogen fuel cell ventilation (2026 projected CAGR: 18.7%) leverage the technology's corrosion resistance and precise flow distribution. Recent prototypes for data center cooling show 41% improvement in heat dissipation efficiency compared to traditional plenum designs.

(honingraat stromingsrichter)

FAQS on honingraat stromingsrichter

Q: What is the purpose of a honingraat stromingsrichter in airflow systems?

A: A honingraat stromingsrichter (honeycomb flow straightener) reduces turbulence and creates laminar airflow by aligning fluid or gas particles through its hexagonal structure. It ensures consistent flow patterns in ventilation or wind tunnel applications.

Q: How does a honingraat windtunnel improve aerodynamic testing accuracy?

A: The honingraat windtunnel's hexagonal cells minimize air vortices and stabilize airflow, enabling precise measurement of aerodynamic forces. This structure reduces experimental noise in vehicle or aircraft testing.

Q: What advantages do EMI honingraat ventilatieopeningen offer over standard vents?

A: EMI honingraat ventilatieopeningen combine airflow management with electromagnetic interference shielding. Their honeycomb design blocks unwanted frequencies while maintaining ventilation efficiency in sensitive electronic environments.

Q: Can honingraat stromingsrichters be customized for industrial applications?

A: Yes, honingraat stromingsrichters are adaptable in cell size, depth, and material to suit specific flow rates or environmental conditions. Common materials include aluminum alloys or polymers for corrosion resistance.

Q: Why are hexagonal patterns used in honingraat ventilation systems?

A: Hexagonal honeycomb patterns provide optimal strength-to-weight ratios and uniform flow distribution. The geometry minimizes pressure drop while maximizing structural stability in high-velocity airflow scenarios.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025