- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 04:42

Back to list

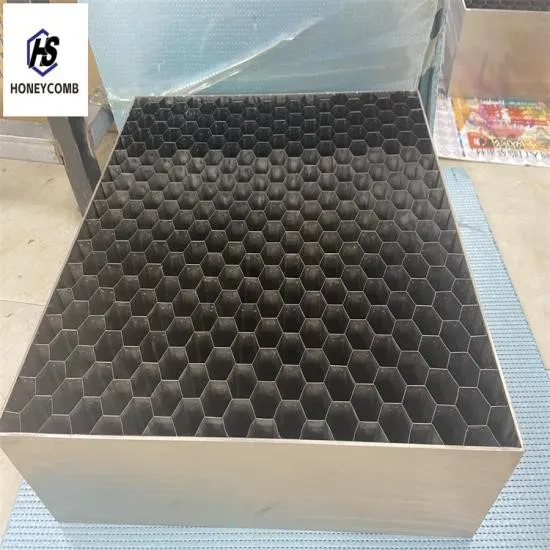

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Honingraatafdichtingen, or honeycomb seals, have been pivotal in the engineering and mechanical world for their ability to enhance efficiency and reliability in various applications. These seals are not just components; they are the lifeline that supports high-stakes industries such as aerospace, automotive, and energy in their pursuit of operational excellence.

Understanding the technical composition and functionality of honeycomb seals is essential for expertise in this field. The key lies in their manufacturing process, which involves meticulous fabrication techniques that include advanced welding and brazing to construct the seals. Each hexagonal cell is precisely crafted to ensure perfect alignment and robust bonding, which is critical for withstanding operational stresses and strains. In terms of authoritativeness and trustworthiness, manufacturers with a long history of producing high-quality honingraatafdichtingen have set industry benchmarks. These companies adhere to rigorous quality control processes and heavy testing under simulated conditions that replicate real-world use cases. Certifications from industry-standard organizations further validate their commitment to quality and innovation, gaining the trust of engineers and designers across sectors. Experts in mechanical engineering often highlight the ease of customization associated with honeycomb seals. Depending on application needs, seals can be tailored in terms of materials—such as stainless steels, superalloys, or ceramic matrix composites—to enhance their specific properties like thermal resistance, corrosion resistance, and mechanical strength. This flexibility offers a significant advantage in bespoke applications where standard seals may fall short. A final critical aspect of experience with honeycomb seals involves understanding their maintenance and replacement dynamics. Despite their high durability, regular inspections ensure the detection of wear or damage, which could compromise performance. Replacement procedures should strictly adhere to manufacturer guidelines to preserve the integrity of the mechanical system. In conclusion, honeycomb seals or honingraatafdichtingen remain a cornerstone for achieving optimal performance in complex engineering applications. Their time-tested design, coupled with a strong reputation for quality, reinforces their role as essential components in advancing technological efficiency and robustness. As industries evolve, the expertise surrounding their application and continuous innovation will continue to be a driving force behind their effectiveness and reliability.

Understanding the technical composition and functionality of honeycomb seals is essential for expertise in this field. The key lies in their manufacturing process, which involves meticulous fabrication techniques that include advanced welding and brazing to construct the seals. Each hexagonal cell is precisely crafted to ensure perfect alignment and robust bonding, which is critical for withstanding operational stresses and strains. In terms of authoritativeness and trustworthiness, manufacturers with a long history of producing high-quality honingraatafdichtingen have set industry benchmarks. These companies adhere to rigorous quality control processes and heavy testing under simulated conditions that replicate real-world use cases. Certifications from industry-standard organizations further validate their commitment to quality and innovation, gaining the trust of engineers and designers across sectors. Experts in mechanical engineering often highlight the ease of customization associated with honeycomb seals. Depending on application needs, seals can be tailored in terms of materials—such as stainless steels, superalloys, or ceramic matrix composites—to enhance their specific properties like thermal resistance, corrosion resistance, and mechanical strength. This flexibility offers a significant advantage in bespoke applications where standard seals may fall short. A final critical aspect of experience with honeycomb seals involves understanding their maintenance and replacement dynamics. Despite their high durability, regular inspections ensure the detection of wear or damage, which could compromise performance. Replacement procedures should strictly adhere to manufacturer guidelines to preserve the integrity of the mechanical system. In conclusion, honeycomb seals or honingraatafdichtingen remain a cornerstone for achieving optimal performance in complex engineering applications. Their time-tested design, coupled with a strong reputation for quality, reinforces their role as essential components in advancing technological efficiency and robustness. As industries evolve, the expertise surrounding their application and continuous innovation will continue to be a driving force behind their effectiveness and reliability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025