- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

honingraatcomponenten

Understanding Honeycomb Components A Deep Dive into Their Structure and Applications

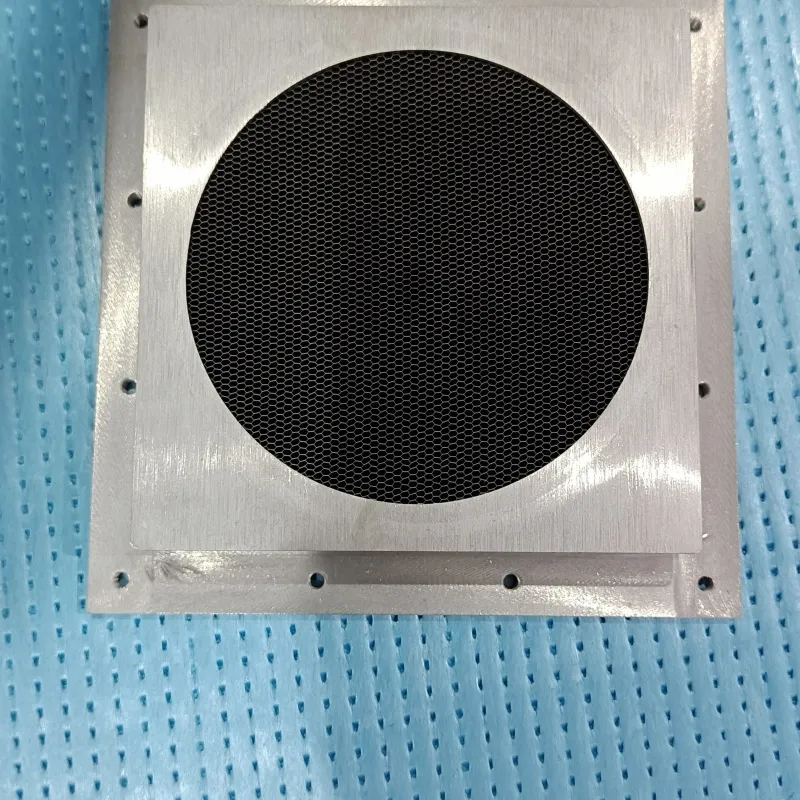

The honeycomb structure is a versatile and efficient design found in nature and extensively applied across various fields, such as architecture, aerospace, and materials science. Inspired by the geometric patterns formed by bees, honeycomb components are primarily made of two materials a core, typically composed of lighter, less dense material, and skin or face sheets that provide structural reinforcement and protection. This innovative design offers numerous advantages, including lightweight properties, high strength-to-weight ratios, and excellent energy absorption capabilities.

The Structure of Honeycomb Components

At the core of honeycomb components is the hexagonal arrangement recognized for its efficiency in filling space. The geometry not only maximizes strength but also minimizes material usage, which is essential for improving performance across various applications. Each cell of a honeycomb acts as an independent unit, distributing load across the entire structure rather than transferring it to one point. This leads to a remarkable ability to withstand deformation under stress, making honeycomb components an advantageous choice for several industries.

Honeycomb cores can be made from various materials, including paper, cardboard, plastic, metal, or composite materials, depending on the desired properties for specific applications. The face sheets that encase the core also come in different materials, such as aluminum, fiberglass, or carbon fiber, contributing additional strength and rigidity. The combination of a lightweight core with the robust skins results in a product that is not only strong but also cost-effective, as less material is used without sacrificing performance.

Applications of Honeycomb Components

1. Aerospace Industry Honeycomb structures have found a prominent place in the aerospace sector due to their lightweight and high-strength characteristics. Aircraft wings, fuselages, and interiors often utilize honeycomb materials to reduce weight while maintaining structural integrity. For instance, the honeycomb panels used in aircraft are essential to enhancing fuel efficiency, leading to significant cost savings and reduced environmental impact.

2. Architecture and Construction In modern architectural designs, honeycomb panels are increasingly incorporated into building facades and interiors to create sleek, aesthetically pleasing structures. These panels possess excellent thermal insulation properties and can contribute to energy-efficient building design. Additionally, their lightweight nature allows for easier installation and less structural modification.

honingraatcomponenten

3. Transportation Beyond aerospace, honeycomb materials are utilized in the automotive industry to produce lightweight components that enhance fuel efficiency. From interior panels to structural elements, honeycomb technology plays a pivotal role in designing vehicles that meet stringent performance and economic standards.

4. Packaging Honeycomb technology is also leveraged in packaging solutions, particularly for fragile items. The inherent cushioning and protective capabilities of honeycomb structures provide a reliable means of safeguarding products during transport, reducing damage and returns.

5. Marine Applications The marine industry benefits from honeycomb structures due to their resistance to corrosion and lightweight properties. Boat hulls, bulkheads, and decks are often designed using honeycomb materials to improve buoyancy and reduce overall vessel weight.

Advantages of Honeycomb Components

The advantages of utilizing honeycomb components go beyond just weight savings. These include

- Enhanced Strength-to-Weight Ratio Honeycomb structures can carry significant loads relative to their weight, providing exceptional performance in high-stress applications. - Energy Absorption The design inherently absorbs energy from impacts, making it an excellent choice for safety applications in various sectors. - Customization Honeycomb cores can be engineered with varying densities and thicknesses to meet specific performance criteria, allowing for tailored solutions across different industries.

Conclusion

In conclusion, honeycomb components exemplify an innovative approach to engineering and design, harnessing the efficiency of natural forms to create products that are lightweight, strong, and versatile. Their applications across various industries demonstrate the adaptability of honeycomb technology and its continued relevance in meeting modern challenges. As research and development in material science progress, we can expect to see even more groundbreaking applications and enhancements in honeycomb component technology.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025