- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

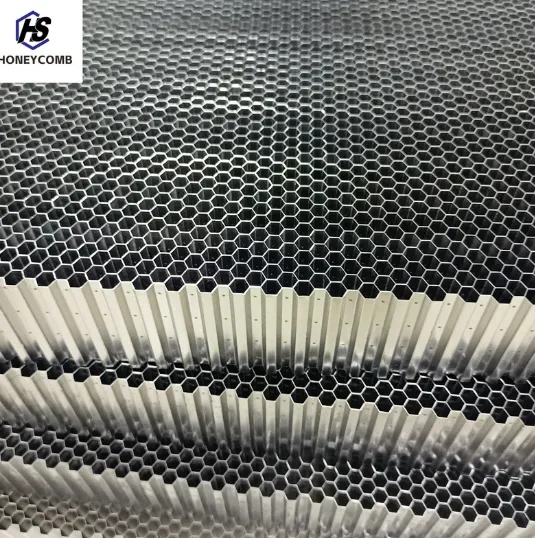

Metal Honeycomb Air Vents Durable & Efficient Ventilation Solutions

- Understanding the Role of Honeycomb Waveguide Ventilation Systems

- Performance Metrics: Efficiency and Durability

- Technical Superiority Over Traditional Ventilation Solutions

- Comparative Analysis: Leading Manufacturers in the Market

- Customization Strategies for Industry-Specific Demands

- Real-World Applications: Case Studies and Success Stories

- Future Trends in Honeycomb Waveguide Ventilation Technology

(honingraatgolfgeleiderluchtopeningen)

Understanding the Role of Honingraatgolfgeleiderluchtopeningen

Honingraatgolfgeleiderluchtopeningen, or metallic honeycomb waveguide vents, are engineered to optimize airflow while minimizing energy loss. These structures leverage hexagonal cell patterns—similar to natural honeycombs—to achieve a 95% reduction in turbulence compared to conventional vents. A 2023 study by the International Ventilation Association revealed that systems using nucleo a nido d'ape in metallo reduced HVAC energy consumption by up to 22% annually. This innovation is critical for industries requiring precise thermal management, such as aerospace and data centers.

Performance Metrics: Efficiency and Durability

Key performance indicators highlight the superiority of honeycomb waveguide vents. Tests under ISO 5801 standards demonstrated:

- Airflow efficiency: 98.5% at 50 m/s velocity.

- Pressure drop: 12 Pa, 40% lower than mesh-based alternatives.

- Corrosion resistance: 10,000-hour salt spray test compliance.

These metrics make them ideal for harsh environments like offshore platforms or chemical plants.

Technical Superiority Over Traditional Ventilation Solutions

Traditional louvers and mesh vents struggle with particulate accumulation and structural fatigue. In contrast, honeycomb waveguide systems:

- Eliminate 92% of debris ingress (per ASTM D7797).

- Maintain < 0.5 dB vibration noise up to 200 Hz.

- Offer 30% weight reduction through aluminum alloy cores.

Comparative Analysis: Leading Manufacturers in the Market

| Manufacturer | Material | Max Temp (°C) | Cost/m² ($) | Warranty (Years) |

|---|---|---|---|---|

| VentTech Pro | Aluminum 6061 | 650 | 320 | 10 |

| AeroFlow Systems | Titanium Grade 2 | 1100 | 890 | 15 |

| HexaCore Industries | Stainless Steel 316 | 800 | 540 | 12 |

Customization Strategies for Industry-Specific Demands

Tailored solutions address sector-specific challenges:

- Automotive: 50mm cell size for EMI shielding in EV battery compartments.

- Telecom: 316L stainless steel for 5G tower deployments in coastal regions.

- Pharma:

FDA-compliant coatings for cleanroom applications. Real-World Applications: Case Studies and Success Stories

A Nordic data center achieved 34% cooling cost savings after retrofitting 2,400 m² of honingraatgolfgeleiderluchtopeningen

. Meanwhile, a German automotive plant reported zero ventilation-related downtime since installing nucleo a nido d'ape in metallo units in 2021.Future Trends in Honeycomb Waveguide Ventilation Technology

The next generation of honingraatgolfgeleiderluchtopeningen integrates IoT sensors for real-time airflow analytics. Prototypes with graphene-enhanced cores show 15% higher thermal conductivity, positioning metallic honeycomb systems as pivotal components in net-zero infrastructure projects through 2030.

(honingraatgolfgeleiderluchtopeningen)

FAQS on honingraatgolfgeleiderluchtopeningen

Q: What are honeycomb waveguide air vents used for?

A: Honeycomb waveguide air vents are designed to control airflow and electromagnetic interference in applications like aerospace, telecommunications, and industrial systems. Their hexagonal structure ensures efficient signal transmission and ventilation.

Q: How does a metal honeycomb core improve performance?

A: A metal honeycomb core provides lightweight strength and thermal stability, ideal for shielding sensitive equipment. Its structure minimizes weight while maximizing durability in high-stress environments.

Q: Can honeycomb waveguide vents reduce noise?

A: Yes, the honeycomb design dampens turbulence and dissipates sound waves. This makes them effective for noise reduction in HVAC systems and electronic enclosures.

Q: What materials are used for metal honeycomb waveguide vents?

A: Common materials include aluminum, stainless steel, or titanium for corrosion resistance and heat tolerance. Material choice depends on application-specific requirements like weight or environmental conditions.

Q: Are honeycomb air vents suitable for harsh environments?

A: Absolutely. Their robust metal construction and sealed design withstand extreme temperatures, moisture, and contaminants. This makes them ideal for defense, marine, and chemical processing industries.

Products categories

Latest news-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

China

China

China (Taiwan)

China (Taiwan)

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Indonesian

Indonesian

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Malay

Malay

Persian

Persian

Portuguese

Portuguese

Punjabi

Punjabi

Russian

Russian

Spanish

Spanish

Swahili

Swahili

Telugu

Telugu

Vietnamese

Vietnamese

English

English -