- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 06, 2025 04:27

Back to list

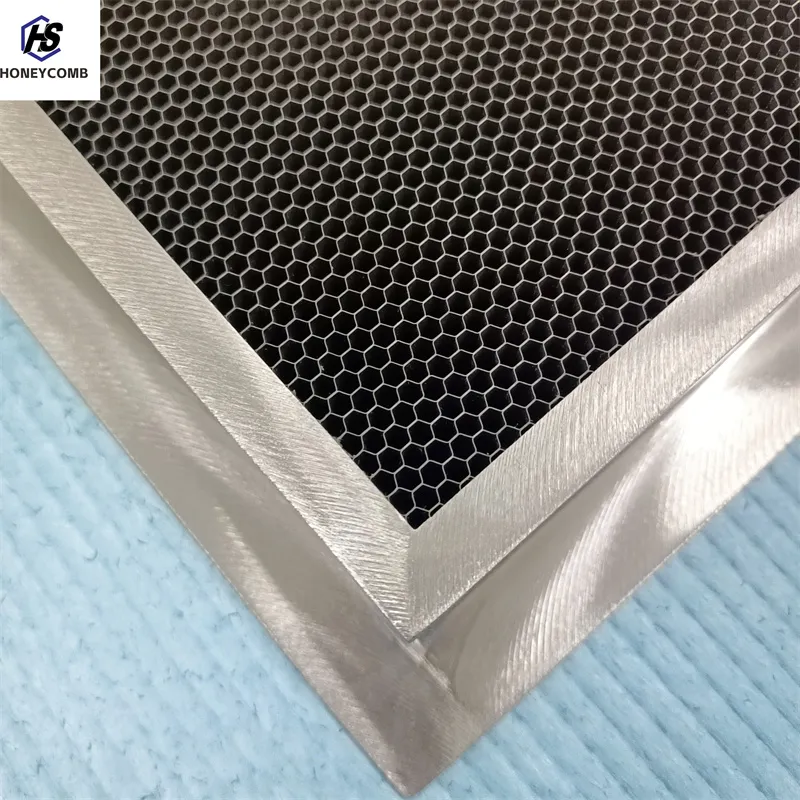

emi honeycomb

In the evolving world of materials and technology, the concept of the honingraatgolfgeleiderluchtopeningen, or honeycomb waveguide air openings, has become increasingly relevant in various industry sectors. This innovative design element not only enhances product performance but also optimizes functionality, making it essential for manufacturers and engineers seeking to elevate their products' efficiency. Here, we delve into the intricate details and applications of such structures, underscoring their significance and proving why they have garnered attention across different fields.

From an authoritative perspective, numerous studies and experimental results highlight the thermal management benefits afforded by these openings. The increased surface area facilitates better heat dissipation, which is critical in electronics and high-performance computing systems. By efficiently managing heat, these systems can operate at peak performance without the risk of overheating, thus extending their lifespan and reliability. Trustworthiness in the application of honeycomb waveguide air openings is further evidenced by their environmental adaptability. Their design is not only energy-efficient but also contributes to sustainable practices by reducing the overall material footprint. In the automotive sector, for example, car manufacturers are increasingly integrating these structures into designs to meet stringent regulatory standards for emissions and fuel economy. Lightweight materials contribute to significant reductions in fuel consumption, thus supporting broader environmental objectives. The value of such innovative engineering solutions extends to architecture as well, where they are used in building facades and insulation solutions. The air gaps within the honeycombs provide excellent insulation properties, reducing the need for excessive energy consumption for heating or cooling. This is especially relevant in regions with extreme temperatures, further positioning honeycomb waveguide air openings as a versatile and eco-friendly solution. In conclusion, as industries continue to demand materials and designs that push the boundaries of performance and sustainability, honeycomb waveguide air openings stand out as a multifaceted solution. Their ability to amalgamate strength, lightweight, performance, and ecological benefits makes them indispensable across various sectors. For professionals seeking to leverage these attributes, an understanding of their potential applications and benefits is crucial. By integrating honeycomb waveguide air openings into product development processes, companies can not only enhance their offerings but also align with modern consumer and environmental expectations, thereby securing a competitive edge in the market.

From an authoritative perspective, numerous studies and experimental results highlight the thermal management benefits afforded by these openings. The increased surface area facilitates better heat dissipation, which is critical in electronics and high-performance computing systems. By efficiently managing heat, these systems can operate at peak performance without the risk of overheating, thus extending their lifespan and reliability. Trustworthiness in the application of honeycomb waveguide air openings is further evidenced by their environmental adaptability. Their design is not only energy-efficient but also contributes to sustainable practices by reducing the overall material footprint. In the automotive sector, for example, car manufacturers are increasingly integrating these structures into designs to meet stringent regulatory standards for emissions and fuel economy. Lightweight materials contribute to significant reductions in fuel consumption, thus supporting broader environmental objectives. The value of such innovative engineering solutions extends to architecture as well, where they are used in building facades and insulation solutions. The air gaps within the honeycombs provide excellent insulation properties, reducing the need for excessive energy consumption for heating or cooling. This is especially relevant in regions with extreme temperatures, further positioning honeycomb waveguide air openings as a versatile and eco-friendly solution. In conclusion, as industries continue to demand materials and designs that push the boundaries of performance and sustainability, honeycomb waveguide air openings stand out as a multifaceted solution. Their ability to amalgamate strength, lightweight, performance, and ecological benefits makes them indispensable across various sectors. For professionals seeking to leverage these attributes, an understanding of their potential applications and benefits is crucial. By integrating honeycomb waveguide air openings into product development processes, companies can not only enhance their offerings but also align with modern consumer and environmental expectations, thereby securing a competitive edge in the market.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025