- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

honingraatmetaal

The Fascinating World of Honeycomb Metal Structure and Applications

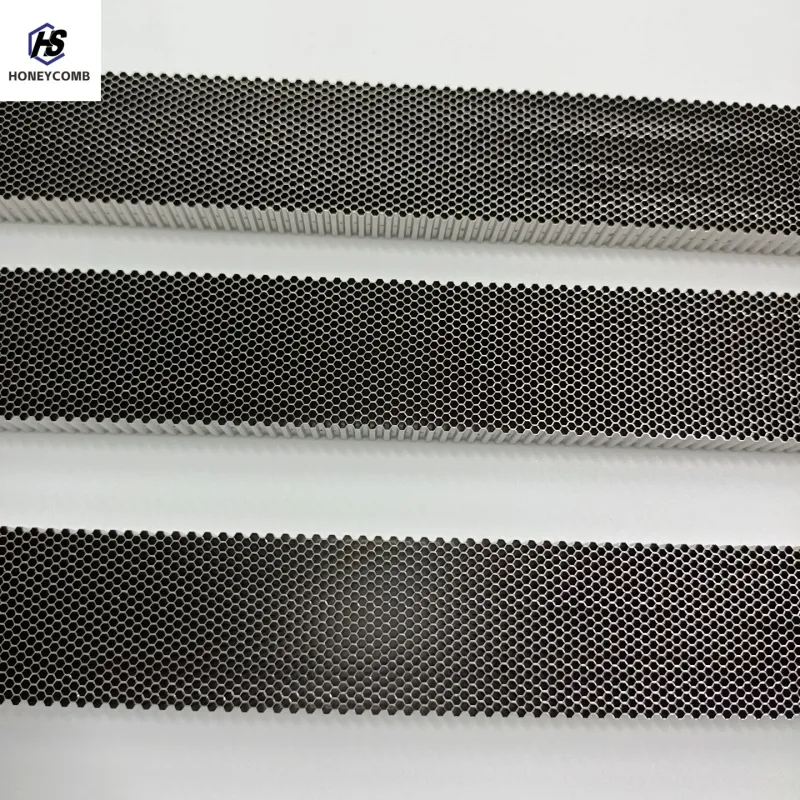

Honeycomb metal, an innovative material characterized by its unique cellular structure, has gained significant attention in various industries due to its remarkable properties. Resembling the natural intricacies of a honeycomb, this lightweight yet robust material has revolutionized the landscape of engineering and design. This article delves into the features, advantages, and applications of honeycomb metal.

Structure and Composition

At its core, honeycomb metal consists of a series of hexagonally-shaped cells bonded together, forming a three-dimensional network. Typically composed of aluminum, stainless steel, or other alloys, this configuration not only minimizes weight but also maximizes strength. The air-filled cells provide excellent rigidity while allowing for a remarkably low density compared to solid metal sheets. This geometry, inspired by natural patterns, optimizes the material’s performance, enabling it to withstand significant loads and stresses.

Properties and Advantages

One of the main attractions of honeycomb metal is its impressive strength-to-weight ratio. By using less material while maintaining structural integrity, honeycomb metal is an ideal choice for applications where weight reduction is crucial, such as aerospace, automotive, and architectural design. Furthermore, its inherent properties also include excellent thermal insulation, sound dampening capabilities, and resistance to corrosion, making it suitable for diverse environments.

Another key advantage is its energy absorption characteristics. Honeycomb structures can dissipate energy efficiently, making them perfect for applications that require impact resistance. This quality is especially valued in transportation industries, where safety regulations mandate the use of materials that can endure abrupt impacts.

honingraatmetaal

Industrial Applications

The applications of honeycomb metal are wide-ranging, reflecting its versatility and performance benefits. In the aerospace industry, it is used extensively in aircraft components and structural elements. The lower weight of honeycomb panels translates to fuel efficiency, which is a critical consideration in aviation. Additionally, these materials can be found in the construction of lightweight wings, fuselages, and other aircraft components that demand high-strength-to-weight integration.

In the automotive sector, manufacturers are increasingly utilizing honeycomb metal for structural panels and components to reduce vehicle weight. Improved fuel economy and enhanced performance are significant advantages gained from this lightweight material. Furthermore, honeycomb metal is often used in crash structures, providing higher levels of safety for passengers in the event of a collision.

Architecture also benefits from honeycomb metal's aesthetic and functional attributes. Designers are incorporating this material into façades, interior partitions, and flooring systems. The appealing geometric patterns and customization options can create visually striking designs while ensuring structural efficiency.

Challenges and Future Prospects

Despite its many advantages, there are challenges associated with the use of honeycomb metal. Manufacturing processes can be complex, and material costs may be higher than traditional alternatives. However, advancements in technology are continuously enhancing production methods, which may mitigate these issues in the future.

In summary, honeycomb metal represents a remarkable fusion of strength, durability, and lightweight properties. Its unique structure not only reflects nature’s design brilliance but also meets the stringent demands of modern engineering. As industries continue to prioritize sustainability and performance, the use of honeycomb metal is likely to expand, opening up new avenues for innovation. As we move into a future increasingly reliant on advanced materials, honeycomb metal stands out as a frontrunner in shaping the designs and functionalities of tomorrow.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025