- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 07, 2025 04:33

Back to list

hvac air flow straightener

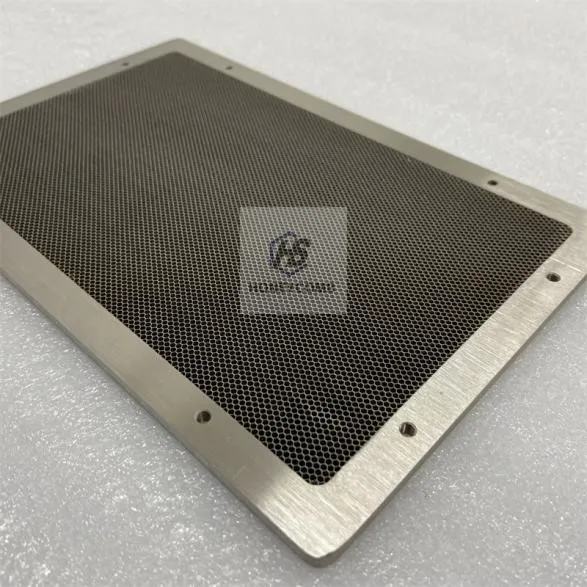

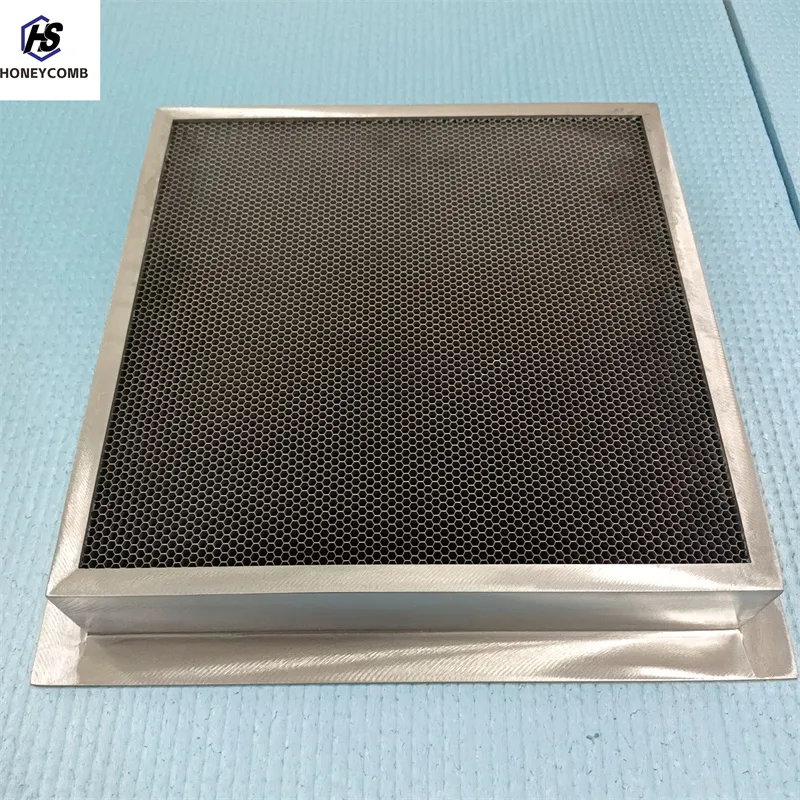

Honeycomb panels, often referred to as honingraatplaat in Dutch, have become a quintessential element in various industries, hailed for their unique combination of lightweight structure and remarkable strength. This article delves into the multifaceted applications, advantages, and expertise surrounding these innovative materials, establishing their irreplaceable presence in today’s market.

Beyond industries, the environmental impact of honeycomb panels underscores their value. Manufactured from recyclable materials, they adhere to eco-friendly practices, reducing waste and promoting environmental stewardship. This aligns with growing global initiatives aimed at limiting environmental footprints, making them a responsible choice for companies committed to sustainability. Expertise in the production of honeycomb panels involves precision engineering and cutting-edge technology to achieve optimum cell configuration and material quality. Industries demand panels fabricated to exact specifications to meet the rigorous standards necessary for safety and performance. Consequently, manufacturers employ advanced computational models and state-of-the-art machinery to ensure consistency and reliability in every panel produced. The authoritative voice on honeycomb technology resonates through extensive research and published findings in engineering journals, highlighting the continuous advancements and innovations in material science. This body of work fortifies the credibility of honeycomb panels, offering assurance to industries that adopt them. Ultimately, the trustworthiness of honeycomb panel applications stems from a proven track record across diverse sectors, reaffirming their position as indispensable components of modern engineering solutions. As designs continue to evolve in response to more stringent requirements, the investment in honeycomb technology is expected to rise, substantiating their place at the forefront of innovation. In conclusion, the expertise and experience encapsulated in the use of honingraatplaat underscore its indispensable role in advancing industrial capabilities while adhering to the highest standards of environmental responsibility and engineering excellence. As the demand for sustainable yet robust materials grows, honeycomb panels remain instrumental in shaping the future of design and functionality across varied landscapes.

Beyond industries, the environmental impact of honeycomb panels underscores their value. Manufactured from recyclable materials, they adhere to eco-friendly practices, reducing waste and promoting environmental stewardship. This aligns with growing global initiatives aimed at limiting environmental footprints, making them a responsible choice for companies committed to sustainability. Expertise in the production of honeycomb panels involves precision engineering and cutting-edge technology to achieve optimum cell configuration and material quality. Industries demand panels fabricated to exact specifications to meet the rigorous standards necessary for safety and performance. Consequently, manufacturers employ advanced computational models and state-of-the-art machinery to ensure consistency and reliability in every panel produced. The authoritative voice on honeycomb technology resonates through extensive research and published findings in engineering journals, highlighting the continuous advancements and innovations in material science. This body of work fortifies the credibility of honeycomb panels, offering assurance to industries that adopt them. Ultimately, the trustworthiness of honeycomb panel applications stems from a proven track record across diverse sectors, reaffirming their position as indispensable components of modern engineering solutions. As designs continue to evolve in response to more stringent requirements, the investment in honeycomb technology is expected to rise, substantiating their place at the forefront of innovation. In conclusion, the expertise and experience encapsulated in the use of honingraatplaat underscore its indispensable role in advancing industrial capabilities while adhering to the highest standards of environmental responsibility and engineering excellence. As the demand for sustainable yet robust materials grows, honeycomb panels remain instrumental in shaping the future of design and functionality across varied landscapes.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025