- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 07, 2025 05:35

Back to list

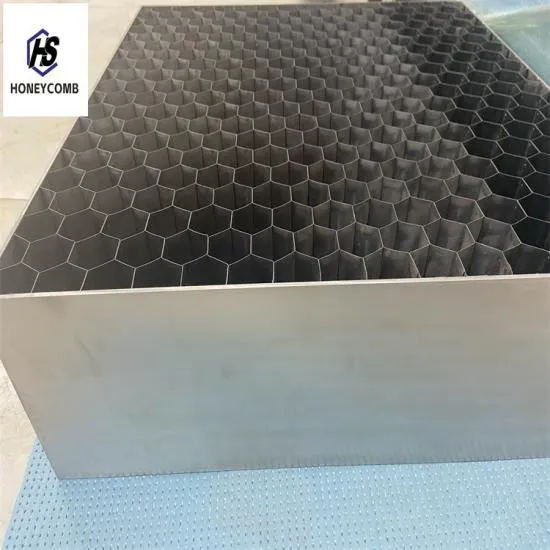

Stainless Steel 304/316L Honeycomb Core for Air Flow Straightener

In the world of construction and design materials, honingraatplaten, or honeycomb panels, stand out due to their remarkable properties and wide range of applications. These panels blend lightweight characteristics with superior strength, offering unique benefits in various sectors, from aerospace to interior design. While their application in diverse industries is growing rapidly, understanding their properties, uses, and the evidence of their effectiveness is crucial for businesses looking to leverage this technology for optimal results.

When discussing trustworthiness and the safety profiles of honingraatplaten, it's crucial to mention their impressive performance in safety tests. These panels exhibit superior resistance to abrupt impacts and stresses, maintaining their structural integrity under conditions that would typically compromise traditional materials. This reliability is crucial in sectors like aviation and automotive, where maintaining structural integrity under stress can be life-saving. Educational institutions leading in material science and engineering confirm the benefits of integrating honeycomb panels into their designs. Research from these bodies consistently highlights the balance between versatility and performance that these panels offer, encouraging more sectors to explore their potential applications. In practical applications, architectural firms are increasingly opting for honingraatplaten for wall claddings and facades. The aesthetic flexibility, combined with structural benefits, makes them an attractive choice for modern designs. Designers and architects appreciate the innovative character these panels add to buildings, allowing for more dynamic and futuristic architectural presentations that are both durable and visually striking. As for the consumer market, awareness and adoption of honingraatplaten are on the rise. Businesses and consumers alike are beginning to demand more sustainable, efficient, and innovative products, values that honeycomb panel manufacturers are more than capable of delivering. Providers of these panels are continuously refining their offerings, enhancing their production capabilities, and ensuring quality standards that meet rigorous industry certifications and approvals. In conclusion, honingraatplaten present a paradigm shift in material application through their unique combination of strength, lightness, and environmental benefits. As industries continue to seek out efficiency and sustainability, these honeycomb panels offer a pathway to significant advancements in design and performance. For businesses looking to innovate and gain competitive advantages, understanding and utilizing the full potential of honigraatplaten is not just an opportunity but a necessity in today's environmentally conscious and performance-driven market.

When discussing trustworthiness and the safety profiles of honingraatplaten, it's crucial to mention their impressive performance in safety tests. These panels exhibit superior resistance to abrupt impacts and stresses, maintaining their structural integrity under conditions that would typically compromise traditional materials. This reliability is crucial in sectors like aviation and automotive, where maintaining structural integrity under stress can be life-saving. Educational institutions leading in material science and engineering confirm the benefits of integrating honeycomb panels into their designs. Research from these bodies consistently highlights the balance between versatility and performance that these panels offer, encouraging more sectors to explore their potential applications. In practical applications, architectural firms are increasingly opting for honingraatplaten for wall claddings and facades. The aesthetic flexibility, combined with structural benefits, makes them an attractive choice for modern designs. Designers and architects appreciate the innovative character these panels add to buildings, allowing for more dynamic and futuristic architectural presentations that are both durable and visually striking. As for the consumer market, awareness and adoption of honingraatplaten are on the rise. Businesses and consumers alike are beginning to demand more sustainable, efficient, and innovative products, values that honeycomb panel manufacturers are more than capable of delivering. Providers of these panels are continuously refining their offerings, enhancing their production capabilities, and ensuring quality standards that meet rigorous industry certifications and approvals. In conclusion, honingraatplaten present a paradigm shift in material application through their unique combination of strength, lightness, and environmental benefits. As industries continue to seek out efficiency and sustainability, these honeycomb panels offer a pathway to significant advancements in design and performance. For businesses looking to innovate and gain competitive advantages, understanding and utilizing the full potential of honigraatplaten is not just an opportunity but a necessity in today's environmentally conscious and performance-driven market.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025