- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 11, 2025 10:17

Back to list

hvac air flow straightener

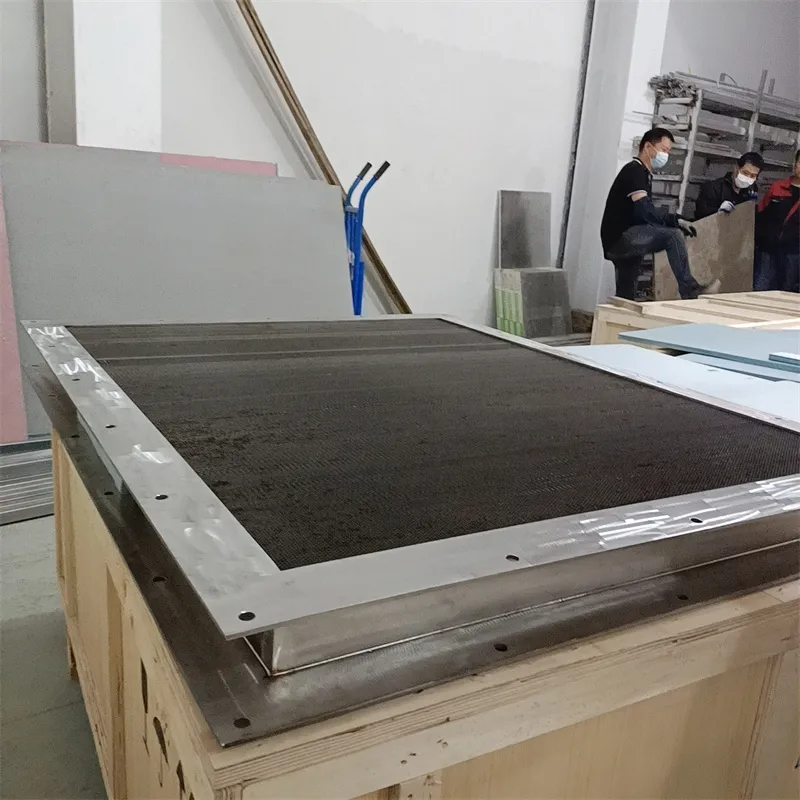

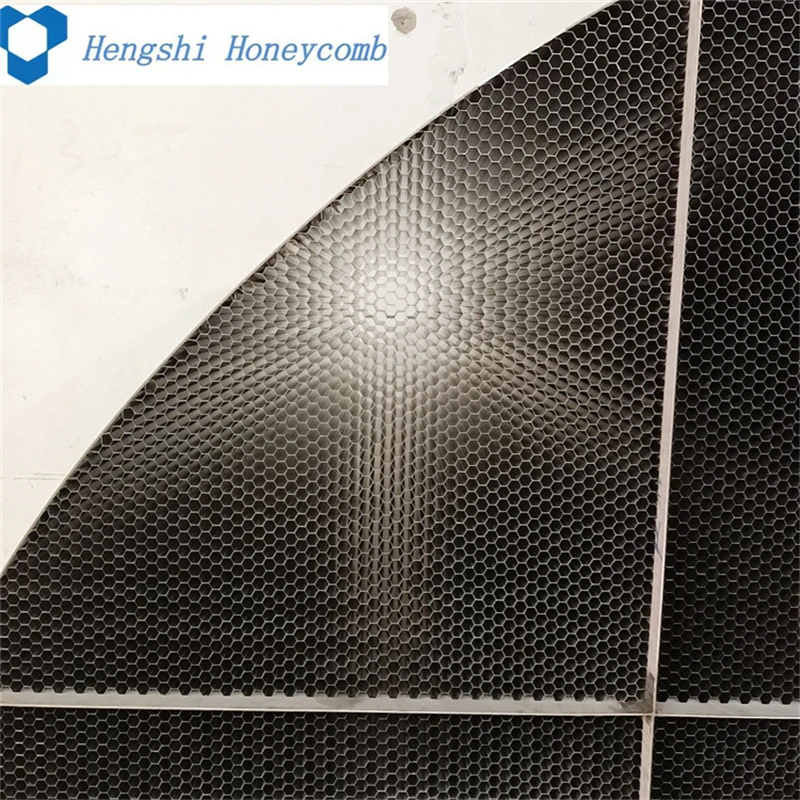

For those venturing into the world of aluminum honeycomb panels, commonly referred to as ceall meala alúmanaim, you’re in good company. With a reputation for unparalleled strength-to-weight ratios, these panels have become cornerstones in industries ranging from aerospace to architecture. This piece will navigate through real-world experiences, delve into the technical expertise that makes these panels stand out, and underline their authoritativeness and trustworthiness in various applications.

Trustworthiness is further enhanced by the sustainable attributes of aluminum honeycomb panels. Aluminum, as a base material, is already celebrated for its recyclability. The production process of these panels often focuses on minimizing waste and promoting environmental responsibility. For industries aiming to meet green building standards, incorporating aluminum honeycomb panels aligns with broader sustainability goals without compromising structural integrity. Professionals across industries acknowledge aluminum honeycomb panels as a revolutionary product. Whether chosen for reducing aircraft weight to increase fuel efficiency or for providing aesthetic flexibility in modern architecture, their impact is undisputed. As you explore what ceall meala alúmanaim has to offer, you'll find yourself at the intersection of innovation and tradition—utilizing a material rooted in historical design yet amplified by modern engineering breakthroughs. For stakeholders in construction, transportation, and design, understanding and adopting aluminum honeycomb panels signifies alignment with cutting-edge technology and sustainable practices. Their continued presence in groundbreaking projects worldwide is a testament to their irreplaceable role in modern industry. This unique blend of real-world application, scientific specialization, authoritative standards, and eco-conscious fabrication showcases these panels not just as materials, but as transformative elements in the landscape of modern development.

Trustworthiness is further enhanced by the sustainable attributes of aluminum honeycomb panels. Aluminum, as a base material, is already celebrated for its recyclability. The production process of these panels often focuses on minimizing waste and promoting environmental responsibility. For industries aiming to meet green building standards, incorporating aluminum honeycomb panels aligns with broader sustainability goals without compromising structural integrity. Professionals across industries acknowledge aluminum honeycomb panels as a revolutionary product. Whether chosen for reducing aircraft weight to increase fuel efficiency or for providing aesthetic flexibility in modern architecture, their impact is undisputed. As you explore what ceall meala alúmanaim has to offer, you'll find yourself at the intersection of innovation and tradition—utilizing a material rooted in historical design yet amplified by modern engineering breakthroughs. For stakeholders in construction, transportation, and design, understanding and adopting aluminum honeycomb panels signifies alignment with cutting-edge technology and sustainable practices. Their continued presence in groundbreaking projects worldwide is a testament to their irreplaceable role in modern industry. This unique blend of real-world application, scientific specialization, authoritative standards, and eco-conscious fabrication showcases these panels not just as materials, but as transformative elements in the landscape of modern development.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025