- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 07:18

Back to list

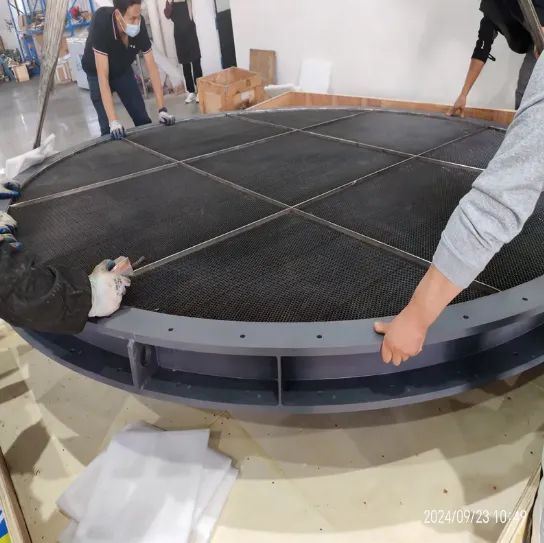

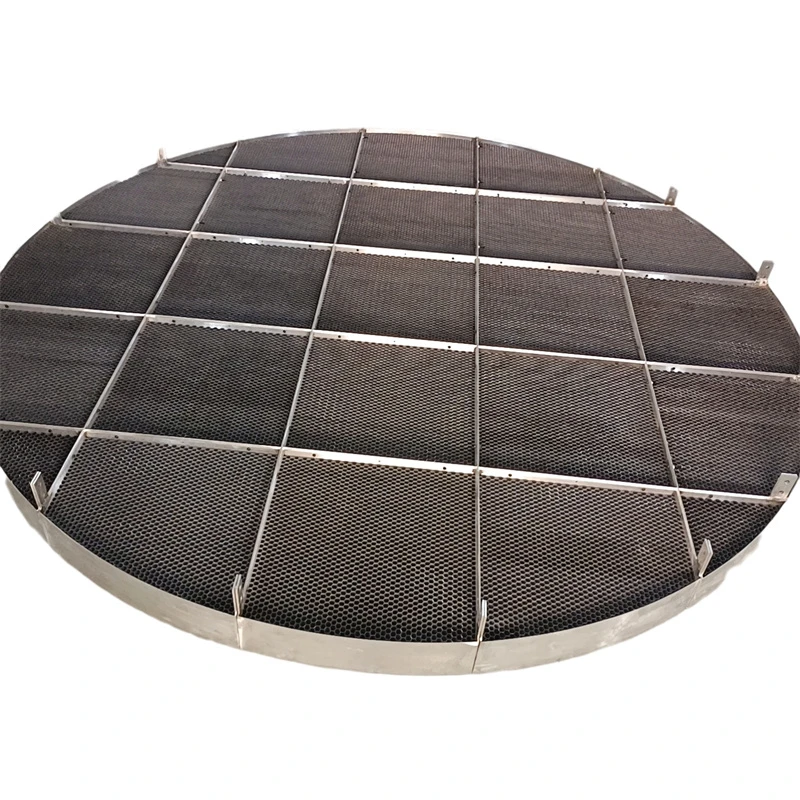

industriell honungskaka

Industrial honeycomb panels have transformed the world of construction and design with their unparalleled strength-to-weight ratio. These innovative panels, inspired by the natural structure of a bee’s honeycomb, offer numerous benefits, making them an indispensable component in various industries.

Moreover, architects and designers are increasingly turning to honeycomb panels for aesthetic structures, where spacious design possibilities and functionality merge. The panels can be used in facades, interior partitions, and floors, allowing for creativity without sacrificing structural integrity. The consistent thickness and uniform strength distribution make them adaptable for complex design forms. This versatility has positioned honeycomb panels as a favorite in sustainable building projects, supporting the future of green architecture. Trust in industrial honeycomb panels also stems from their sustainability. Their production involves less raw material while offering recyclable options, which aligns with global initiatives towards greener industrial practices. In a world increasingly prioritizing eco-friendly solutions, industries utilizing honeycomb technology demonstrate a commitment to sustainable progress. Experts emphasize the need to ensure product authenticity when sourcing honeycomb panels. Quality varies significantly across manufacturers, which means investing time in researching and selecting reputable suppliers is crucial. Compromising on quality in industrial settings could lead to failures, loss, or increased costs in the long term. In conclusion, industrial honeycomb panels represent a fusion of natural inspiration and advanced engineering, providing powerful, adaptable, and environmentally-friendly solutions. Their expertise-backed applications across various industries attest to their design strength, durability, and sustainability. Integrating honeycomb panel solutions into projects not only innovates but also optimizes cost and performance, underlining their indispensable role in the advancement of modern industry.

Moreover, architects and designers are increasingly turning to honeycomb panels for aesthetic structures, where spacious design possibilities and functionality merge. The panels can be used in facades, interior partitions, and floors, allowing for creativity without sacrificing structural integrity. The consistent thickness and uniform strength distribution make them adaptable for complex design forms. This versatility has positioned honeycomb panels as a favorite in sustainable building projects, supporting the future of green architecture. Trust in industrial honeycomb panels also stems from their sustainability. Their production involves less raw material while offering recyclable options, which aligns with global initiatives towards greener industrial practices. In a world increasingly prioritizing eco-friendly solutions, industries utilizing honeycomb technology demonstrate a commitment to sustainable progress. Experts emphasize the need to ensure product authenticity when sourcing honeycomb panels. Quality varies significantly across manufacturers, which means investing time in researching and selecting reputable suppliers is crucial. Compromising on quality in industrial settings could lead to failures, loss, or increased costs in the long term. In conclusion, industrial honeycomb panels represent a fusion of natural inspiration and advanced engineering, providing powerful, adaptable, and environmentally-friendly solutions. Their expertise-backed applications across various industries attest to their design strength, durability, and sustainability. Integrating honeycomb panel solutions into projects not only innovates but also optimizes cost and performance, underlining their indispensable role in the advancement of modern industry.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025