- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 03:17

Back to list

stainless steel honeycomb cookware

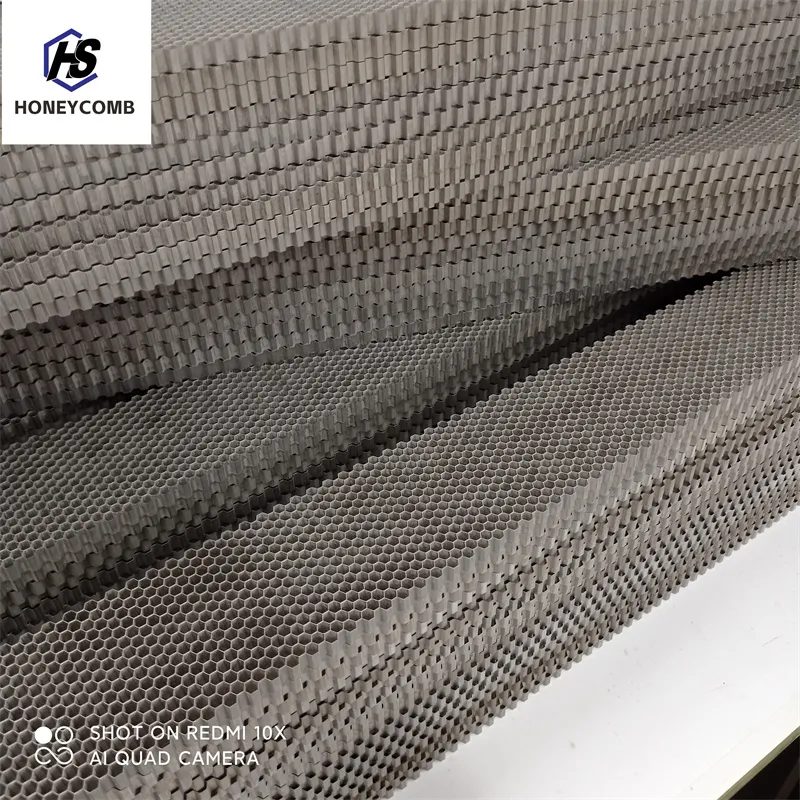

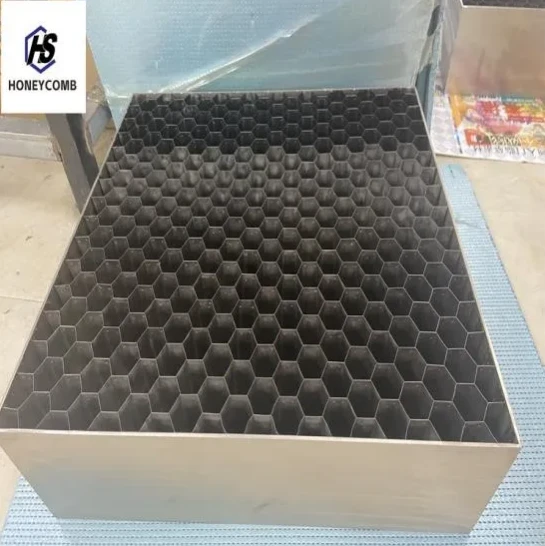

In the world of industrial design and construction, finding materials that offer a blend of strength, durability, and versatility is paramount. Steel honeycomb panels, or lamiera a nido d'ape in acciaio, are one such material that has been revolutionizing industries with their robust and multifaceted attributes.

In aerospace applications, steel honeycomb panels are unmatched in their ability to provide robust structural components while minimizing weight. Aircraft manufacturers leverage these panels in flooring, wing components, and other critical structural parts to maximize performance and fuel efficiency. The panels' inherent strength and impact resistance also bolster aircraft safety, ensuring they endure the rigorous demands of flight and adverse weather conditions. In construction, particularly in areas prone to seismic activity, steel honeycomb panels are crucial. Their ability to withstand forces and maintain structural integrity under stress makes them ideal for building earthquake-resistant structures. With growing concerns about climate change and natural disasters, the adoption of such resilient materials is becoming increasingly important in modern architectural practices. For automotive applications, these panels are used in the manufacturing of car body parts, providing strength and reducing overall vehicle weight. This not only improves fuel efficiency but also enhances vehicle handling and safety. Automakers continue to explore innovative uses of steel honeycomb panels to address the ever-evolving demands for safer, more efficient vehicles. Trust in steel honeycomb panels is backed by rigorous testing and certification processes. Manufacturers adhere to stringent quality control standards to ensure that each panel meets exact specifications. Engineers and architects rely on documented performance records that underscore the reliability and proven capabilities of these panels in diverse applications, from everyday items to high-stakes engineering projects. To conclude, the adoption of lamiera a nido d'ape in acciaio or steel honeycomb panels represents a significant leap forward in materials technology. Their unique design and exceptional properties address critical challenges across multiple industries, driving innovation and environmental responsibility. With continued advancements in manufacturing techniques and engineering applications, the future of steel honeycomb panels holds great promise for further enhancing the efficiency and sustainability of numerous industrial processes.

In aerospace applications, steel honeycomb panels are unmatched in their ability to provide robust structural components while minimizing weight. Aircraft manufacturers leverage these panels in flooring, wing components, and other critical structural parts to maximize performance and fuel efficiency. The panels' inherent strength and impact resistance also bolster aircraft safety, ensuring they endure the rigorous demands of flight and adverse weather conditions. In construction, particularly in areas prone to seismic activity, steel honeycomb panels are crucial. Their ability to withstand forces and maintain structural integrity under stress makes them ideal for building earthquake-resistant structures. With growing concerns about climate change and natural disasters, the adoption of such resilient materials is becoming increasingly important in modern architectural practices. For automotive applications, these panels are used in the manufacturing of car body parts, providing strength and reducing overall vehicle weight. This not only improves fuel efficiency but also enhances vehicle handling and safety. Automakers continue to explore innovative uses of steel honeycomb panels to address the ever-evolving demands for safer, more efficient vehicles. Trust in steel honeycomb panels is backed by rigorous testing and certification processes. Manufacturers adhere to stringent quality control standards to ensure that each panel meets exact specifications. Engineers and architects rely on documented performance records that underscore the reliability and proven capabilities of these panels in diverse applications, from everyday items to high-stakes engineering projects. To conclude, the adoption of lamiera a nido d'ape in acciaio or steel honeycomb panels represents a significant leap forward in materials technology. Their unique design and exceptional properties address critical challenges across multiple industries, driving innovation and environmental responsibility. With continued advancements in manufacturing techniques and engineering applications, the future of steel honeycomb panels holds great promise for further enhancing the efficiency and sustainability of numerous industrial processes.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025