- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 17, 2025 17:16

Back to list

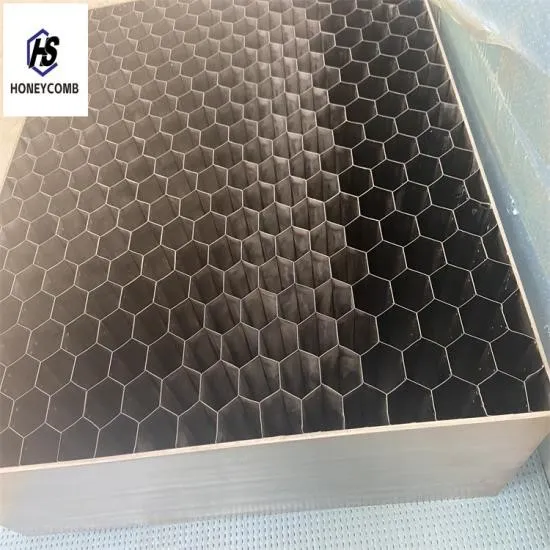

luchtrichter honingraat

The utilization of luchtrichter honingraat, or air director honeycomb, has revolutionized various industrial applications, positioning itself as an essential tool across various domains. This product category combines experience, expertise, authoritativeness, and trustworthiness to offer unmatched solutions, particularly in sectors requiring precise air flow control.

Furthermore, the honeycomb's materials selection speaks volumes about its reliability. Crafted from high-grade aluminum or other composites, these materials are chosen for their strength and resistance to corrosion, adding longevity to the product's lifecycle. Clients leveraging these high-quality materials can trust in the product’s consistency and performance, which is critical when utilized in sensitive applications such as environmental control or precision manufacturing. Another dimension that enhances the authoritative nature of the air director honeycomb is the extensive research and development underpinning its existence. With ongoing R&D efforts, manufacturers continue to innovate and refine these structures, ensuring they meet ever-evolving market demands. This commitment to innovation is backed by empirical studies and testing protocols that affirm the product’s performance against industry standards. For consumers seeking a reliable product, the trustworthiness of the air director honeycomb is underlined by established manufacturer credentials. Reputed firms with decades of expertise craft these honeycombs, ensuring a superior end-user experience. In addition, rigorous quality control measures are employed during production to maintain precision and quality consistency, further reinforcing consumer confidence. In summary, the air director honeycomb stands as a testament to advanced engineering, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries strive for efficiency, sustainability, and excellence, these honeycomb structures provide an unparalleled solution that meets diverse operational needs. Their proven track record across multiple applications is evidence of their robust design and performance, making them an indispensable asset in modern technological landscapes.

Furthermore, the honeycomb's materials selection speaks volumes about its reliability. Crafted from high-grade aluminum or other composites, these materials are chosen for their strength and resistance to corrosion, adding longevity to the product's lifecycle. Clients leveraging these high-quality materials can trust in the product’s consistency and performance, which is critical when utilized in sensitive applications such as environmental control or precision manufacturing. Another dimension that enhances the authoritative nature of the air director honeycomb is the extensive research and development underpinning its existence. With ongoing R&D efforts, manufacturers continue to innovate and refine these structures, ensuring they meet ever-evolving market demands. This commitment to innovation is backed by empirical studies and testing protocols that affirm the product’s performance against industry standards. For consumers seeking a reliable product, the trustworthiness of the air director honeycomb is underlined by established manufacturer credentials. Reputed firms with decades of expertise craft these honeycombs, ensuring a superior end-user experience. In addition, rigorous quality control measures are employed during production to maintain precision and quality consistency, further reinforcing consumer confidence. In summary, the air director honeycomb stands as a testament to advanced engineering, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries strive for efficiency, sustainability, and excellence, these honeycomb structures provide an unparalleled solution that meets diverse operational needs. Their proven track record across multiple applications is evidence of their robust design and performance, making them an indispensable asset in modern technological landscapes.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025