- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 25, 2025 01:00

Back to list

luftglättereinlass

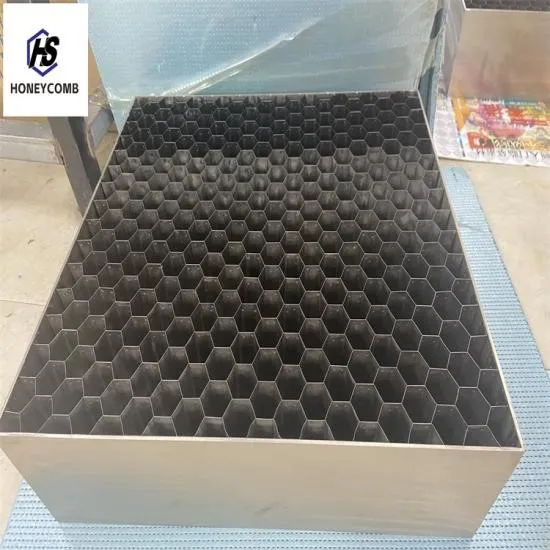

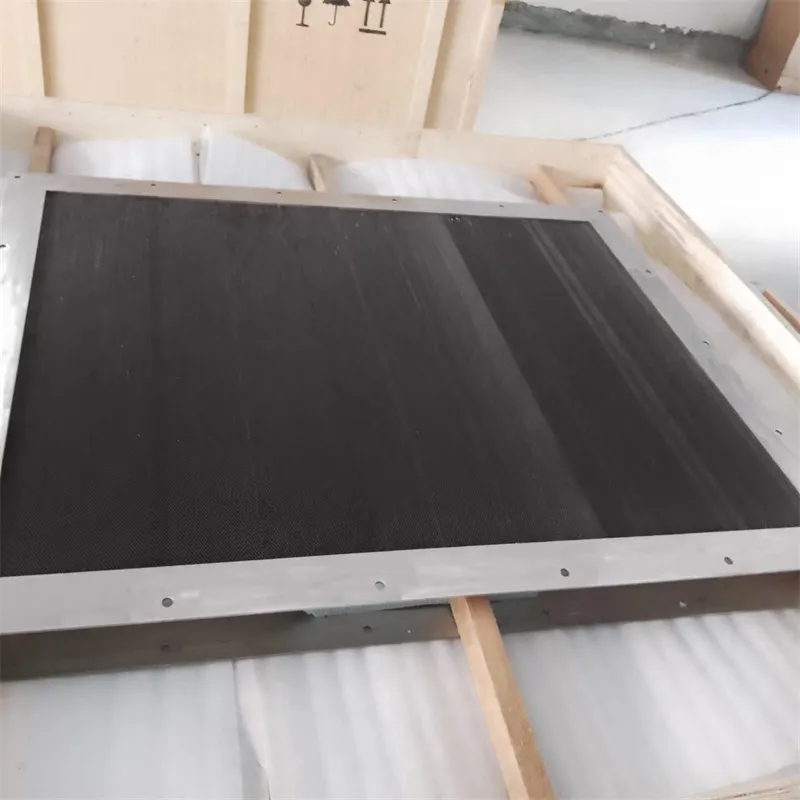

Luftglättereinlass, often translated as air smoothing inlet, stands at the forefront of innovative design in aerodynamic engineering. This component plays a pivotal role in enhancing the performance of various applications, ranging from automotive to aerospace and industrial machinery. With decades of industrial evolution, the luftglättereinlass has not only improved product efficiency but has also contributed significantly to energy conservation and environmental sustainability.

Trust in luftglättereinlass technology is reinforced by empirical evidence and industry studies demonstrating their efficacy. Research consistently shows that engines operating with these specially designed inlets exhibit up to a 20% improvement in performance metrics such as fuel efficiency and power output. Moreover, with global regulatory conditions becoming increasingly stringent, the role of luftglättereinlass in reducing emissions aligns with both industry standards and environmental goals. In industrial setups beyond transportation, luftglättereinlass components also find applications in HVAC systems and large-scale manufacturing operations. Their ability to optimize airflow translates to measurable gains in operational costs and energy efficiency. This versatility speaks volumes about the adaptability of the component, making it a staple in diverse engineering solutions. Investing in luftglättereinlass technology showcases a forward-thinking approach, aligning with the need for sustainable and efficient technological solutions. Customers can rest assured knowing that products equipped with these components are engineered with the highest standards of precision and performance in mind. As industries evolve, so too will the applications and capabilities of luftglättereinlass, paving the way for new innovations in the years to come. For businesses and manufacturers, understanding and leveraging the full potential of luftglättereinlass can lead to substantial competitive advantages. It allows for the development of products that not only meet but exceed current performance standards while maintaining a firm commitment to environmental responsibility. As such, the luftglättereinlass remains an essential element in the landscape of modern engineering and product development.

Trust in luftglättereinlass technology is reinforced by empirical evidence and industry studies demonstrating their efficacy. Research consistently shows that engines operating with these specially designed inlets exhibit up to a 20% improvement in performance metrics such as fuel efficiency and power output. Moreover, with global regulatory conditions becoming increasingly stringent, the role of luftglättereinlass in reducing emissions aligns with both industry standards and environmental goals. In industrial setups beyond transportation, luftglättereinlass components also find applications in HVAC systems and large-scale manufacturing operations. Their ability to optimize airflow translates to measurable gains in operational costs and energy efficiency. This versatility speaks volumes about the adaptability of the component, making it a staple in diverse engineering solutions. Investing in luftglättereinlass technology showcases a forward-thinking approach, aligning with the need for sustainable and efficient technological solutions. Customers can rest assured knowing that products equipped with these components are engineered with the highest standards of precision and performance in mind. As industries evolve, so too will the applications and capabilities of luftglättereinlass, paving the way for new innovations in the years to come. For businesses and manufacturers, understanding and leveraging the full potential of luftglättereinlass can lead to substantial competitive advantages. It allows for the development of products that not only meet but exceed current performance standards while maintaining a firm commitment to environmental responsibility. As such, the luftglättereinlass remains an essential element in the landscape of modern engineering and product development.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025