- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 07, 2025 03:25

Back to list

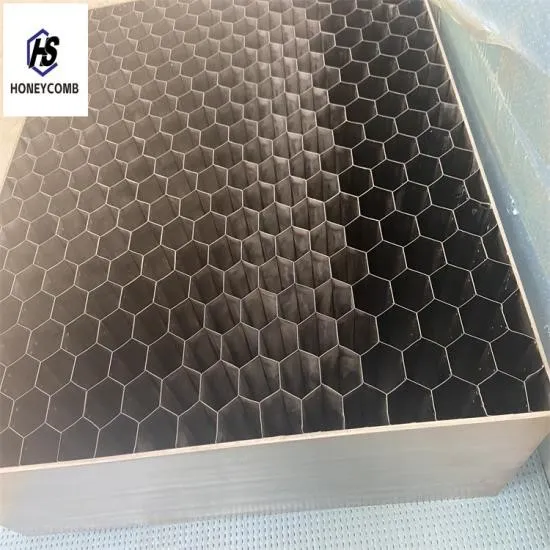

intake air straightener

In the ever-evolving landscape of materials engineering, honeycomb core materials have emerged as a transformative option for numerous industries. The innovative design and superior characteristics of these materials offer compelling solutions to a range of engineering challenges. As an expert in the field with years of experience, I have witnessed firsthand how honeycomb core materials reshape structural efficiency and cost-effectiveness.

From an engineering perspective, the unique properties of honeycomb cores — such as high compression strength, resilience to dynamic loads, and excellent thermal insulation — make them suitable for use in building facades and flooring systems. Civil engineers capitalizing on these materials have reported improvements in durability and energy efficiency of structures. In seismic-prone regions, buildings utilizing honeycomb core materials demonstrate increased resistance to dynamic stresses, thereby reinforcing trust in their safety and reliability. The development and continuous advancement of honeycomb core materials also underscore their authoritative standing in material sciences. Researchers are exploring new composite variations, integrating advanced resins with traditional cores to enhance their properties. Innovations such as carbon-fiber-reinforced honeycombs push the boundaries even further, offering unprecedented applications in cutting-edge fields like space exploration and advanced robotics. Trustworthiness in honeycomb core materials is fortified through rigorous standardization and testing, ensuring they meet international safety and quality benchmarks. Industrial certifications and material traceability further consolidate their status as a reliable choice across various sectors. In summary, the multifaceted advantages of honeycomb core materials — encompassing weight efficiency, strength, sustainability, and cost-effectiveness — continue to affirm their crucial role in contemporary material engineering. This comprehensive understanding underscores the material's pivotal contributions to diverse engineering projects, highlighting both an enduring commitment to innovation and an unwavering pursuit of excellence. The insights drawn from real-world applications and continuous research further solidify honeycomb core materials as a cornerstone of modern engineering, driving progress and enabling pioneering solutions across industries.

From an engineering perspective, the unique properties of honeycomb cores — such as high compression strength, resilience to dynamic loads, and excellent thermal insulation — make them suitable for use in building facades and flooring systems. Civil engineers capitalizing on these materials have reported improvements in durability and energy efficiency of structures. In seismic-prone regions, buildings utilizing honeycomb core materials demonstrate increased resistance to dynamic stresses, thereby reinforcing trust in their safety and reliability. The development and continuous advancement of honeycomb core materials also underscore their authoritative standing in material sciences. Researchers are exploring new composite variations, integrating advanced resins with traditional cores to enhance their properties. Innovations such as carbon-fiber-reinforced honeycombs push the boundaries even further, offering unprecedented applications in cutting-edge fields like space exploration and advanced robotics. Trustworthiness in honeycomb core materials is fortified through rigorous standardization and testing, ensuring they meet international safety and quality benchmarks. Industrial certifications and material traceability further consolidate their status as a reliable choice across various sectors. In summary, the multifaceted advantages of honeycomb core materials — encompassing weight efficiency, strength, sustainability, and cost-effectiveness — continue to affirm their crucial role in contemporary material engineering. This comprehensive understanding underscores the material's pivotal contributions to diverse engineering projects, highlighting both an enduring commitment to innovation and an unwavering pursuit of excellence. The insights drawn from real-world applications and continuous research further solidify honeycomb core materials as a cornerstone of modern engineering, driving progress and enabling pioneering solutions across industries.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025