- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 06, 2025 16:29

Back to list

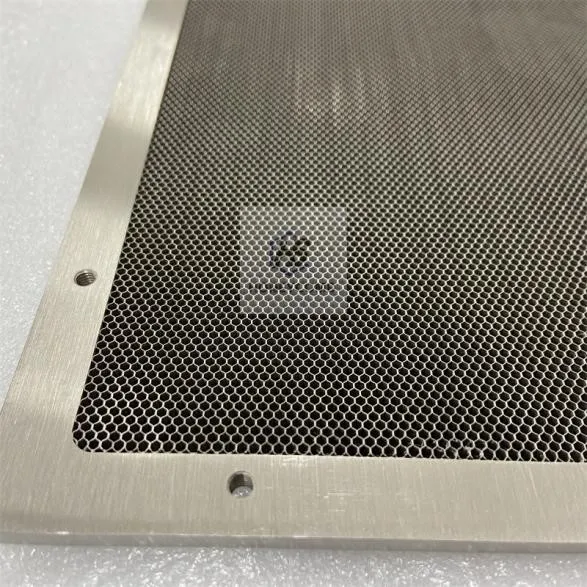

Stainless Steel Honeycomb Air Flow Straightener for Aerospace Testing

Metal em favo de mel, often translated as honeycomb metal, is a revolutionary material that has gained significant attention across various industries due to its unique structural and functional properties. The concept of using a metal structured like a honeycomb isn't just innovative—it has the potential to transform product development and industry standards globally.

Trustworthiness Companies investing in metal em favo de mel benefit from its proven track record. Clients and end-users trust products developed with this material due to their durability and performance. Whether it's car manufacturers aiming for higher fuel efficiency, construction firms prioritizing safety and sustainability, or tech companies developing durable consumer electronics, the reliability of honeycomb metal structures is increasingly becoming a business-critical factor. In real-world applications, these metal structures are versatile. For the aerospace industry, metal em favo de mel reduces aircraft weight, directly translating to fuel savings and less environmental impact. In automotive manufacturing, the high impact resistance ensures passenger safety without compromising on vehicle performance or aesthetics. Meanwhile, in the field of architecture, its lightweight nature allows for innovative design pursuits, including grand ceilings and expansive bridges that would otherwise be structurally impractical. Honeycomb metals are also gaining traction in consumer electronics, where efficient thermal management is crucial. Devices equipped with metal em favo de mel structures dissipate heat more rapidly, enhancing device longevity and performance—an essential attribute in the age of miniaturized, high-powered gadgets. The continuous evolution of metal em favo de mel technologies is supported by expanding research in nanotechnology and environmental sciences, promising even more sophisticated applications and eco-efficient production methods. This scientific progress ensures that the material not only meets current industry requirements but is future-ready, aligning perfectly with global sustainability goals. In conclusion, metal em favo de mel represents a confluence of nature-inspired ingenuity and cutting-edge material science. Its adoption across vast domains reflects growing confidence in its capabilities—heralding a future where materials are lighter, stronger, and more efficient. The industries that embrace this innovation will not only enhance their product offerings but also contribute to a greener, more sustainable planet.

Trustworthiness Companies investing in metal em favo de mel benefit from its proven track record. Clients and end-users trust products developed with this material due to their durability and performance. Whether it's car manufacturers aiming for higher fuel efficiency, construction firms prioritizing safety and sustainability, or tech companies developing durable consumer electronics, the reliability of honeycomb metal structures is increasingly becoming a business-critical factor. In real-world applications, these metal structures are versatile. For the aerospace industry, metal em favo de mel reduces aircraft weight, directly translating to fuel savings and less environmental impact. In automotive manufacturing, the high impact resistance ensures passenger safety without compromising on vehicle performance or aesthetics. Meanwhile, in the field of architecture, its lightweight nature allows for innovative design pursuits, including grand ceilings and expansive bridges that would otherwise be structurally impractical. Honeycomb metals are also gaining traction in consumer electronics, where efficient thermal management is crucial. Devices equipped with metal em favo de mel structures dissipate heat more rapidly, enhancing device longevity and performance—an essential attribute in the age of miniaturized, high-powered gadgets. The continuous evolution of metal em favo de mel technologies is supported by expanding research in nanotechnology and environmental sciences, promising even more sophisticated applications and eco-efficient production methods. This scientific progress ensures that the material not only meets current industry requirements but is future-ready, aligning perfectly with global sustainability goals. In conclusion, metal em favo de mel represents a confluence of nature-inspired ingenuity and cutting-edge material science. Its adoption across vast domains reflects growing confidence in its capabilities—heralding a future where materials are lighter, stronger, and more efficient. The industries that embrace this innovation will not only enhance their product offerings but also contribute to a greener, more sustainable planet.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025