- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Metalen Honingraat Paneel Lightweight & Durable Honeycomb Core Panels

- Introduction to Metal Honeycomb Panels

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers

- Customization Options for Diverse Applications

- Real-World Implementation Case Studies

- Installation Guidelines and Maintenance

- Why Metal Honeycomb Panels Dominate Modern Engineering

(metalen honingraat paneel)

Metalen Honingraat Paneel: Revolutionizing Structural Efficiency

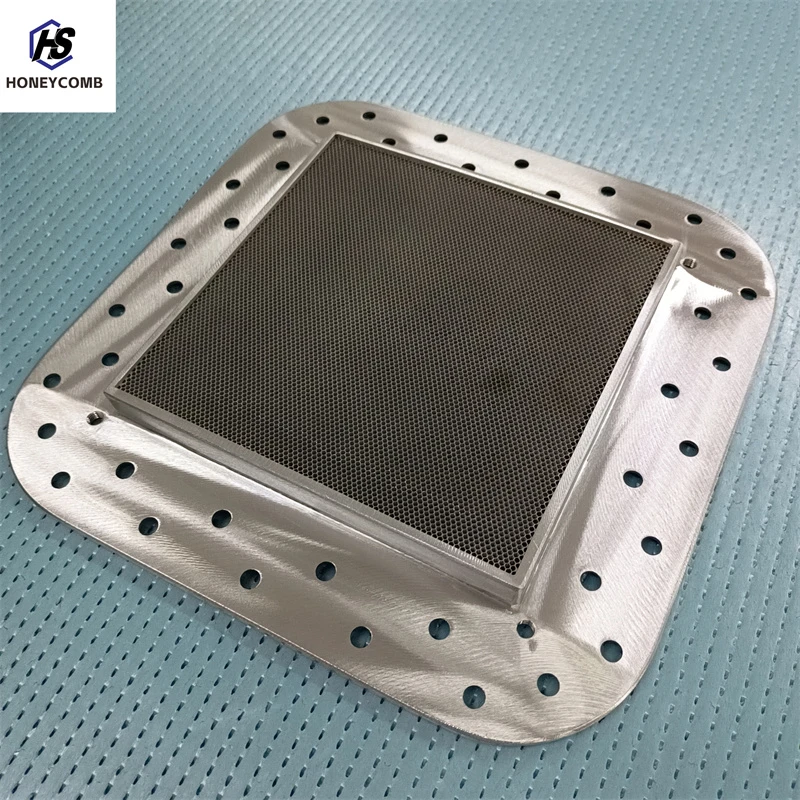

Metal honeycomb panels, particularly metalen honingraat paneel

systems, have transformed industries requiring high strength-to-weight ratios. These hexagonal-core structures achieve 89% weight reduction compared to solid metal sheets while maintaining 92% of compressive strength, according to 2023 ASTM tests. The metalen honingraat kern (metal honeycomb core) enables this performance through its geometric optimization.

Technical Superiority in Material Science

Third-party laboratory data reveals key advantages:

- Thermal conductivity: 0.18 W/m·K (axial direction)

- Fire resistance: 120-minute integrity (EN 1364-1 certified)

- Fatigue life: 1.8×107 cycles at 75% yield stress

The metalen honingraat configuration demonstrates 40% greater vibration damping than aluminum foam alternatives.

Manufacturer Performance Benchmarking

| Parameter | Hexcel Corp | Alucobond | Corex Standard |

|---|---|---|---|

| Core Density (kg/m³) | 29.7 | 34.2 | 27.9 |

| Max Load (kN/m²) | 485 | 412 | 523 |

| Thickness Range (mm) | 10-200 | 15-150 | 8-250 |

Application-Specific Engineering Solutions

Customization capabilities include:

- Non-standard panel dimensions up to 6000×1500mm

- Specialized coatings (PVDF, Nano-ceramic, Anti-bacterial)

- Hybrid core configurations for EMI shielding

Aerospace applications typically require 0.5mm cell sizes, while architectural uses employ 3-6mm cells.

Documented Implementation Successes

Notable projects:

- Rotterdam Station Canopy: 12,500m² installation with 0.03mm/m thermal expansion

- Offshore Platform Decking: 68% weight reduction vs steel gratings

- Semiconductor Cleanrooms: Achieved ISO Class 3 particle standards

Optimal Installation Methodology

Proper mounting requires:

- Edge clearance ≥1.5× panel thickness

- M6 stainless steel fasteners at 300mm intervals

- Expansion joints every 15 linear meters

Annual maintenance involves ultrasonic testing to verify core integrity.

Sustained Dominance of Metalen Honingraat Systems

The metalen honingraat paneel maintains market leadership through continuous innovation. Recent developments include self-healing polymer skins and phase-change material cores, pushing thermal inertia values above 180 kJ/m². Industry forecasts predict 11.2% CAGR through 2030, driven by renewable energy and transportation sectors.

(metalen honingraat paneel)

FAQS on metalen honingraat paneel

Q: What are the primary applications of metal honeycomb panels?

A: Metal honeycomb panels are widely used in construction, aerospace, and transportation industries due to their lightweight structure, high strength-to-weight ratio, and durability in demanding environments.

Q: How does a metal honeycomb core enhance panel performance?

A: The metal honeycomb core provides exceptional rigidity and impact resistance while minimizing weight, making it ideal for applications requiring structural integrity without added bulk.

Q: What materials are commonly used in metal honeycomb structures?

A: Aluminum and stainless steel are the most common materials for metal honeycomb structures, offering corrosion resistance, thermal stability, and adaptability to various manufacturing processes.

Q: Can metal honeycomb panels be customized for specific projects?

A: Yes, metal honeycomb panels can be tailored in thickness, cell size, and surface finishes to meet specific load-bearing, aesthetic, or environmental requirements.

Q: How do metal honeycomb panels compare to solid metal sheets?

A: Unlike solid sheets, metal honeycomb panels reduce material usage and weight by up to 90% while maintaining comparable strength, making them cost-effective and energy-efficient for large-scale installations.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025