- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 12:06

Back to list

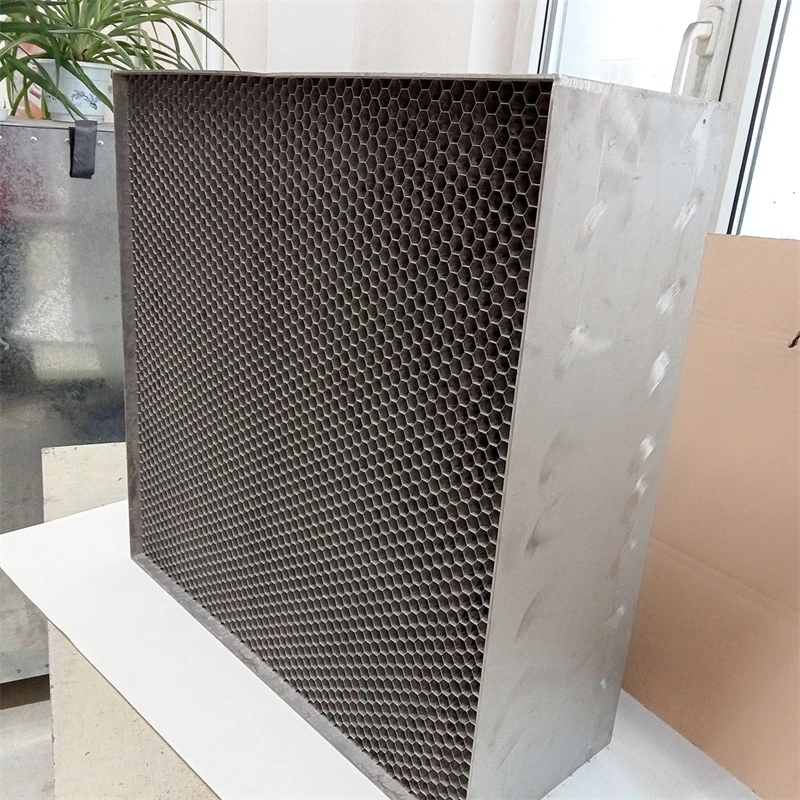

metal honeycomb

The innovative evolution of the metal honeycomb structure has significantly impacted various industries due to its unique blend of lightweight characteristics, robust strength, and remarkable versatility. Leveraging decades of research and engineering expertise, the metal honeycomb has become indispensable in sectors ranging from aerospace to automotive manufacturing, and even in the design of sustainable architecture.

Manufacturers producing these metal honeycomb products adhere to stringent quality control measures, ensuring each product meets international standards. Expertise in alloy selection allows for customization, accommodating specific needs such as corrosion resistance or thermal conductivity. Trust in these products is further reinforced through certifications by recognized industry bodies, presenting an authoritative assurance of their performance and reliability. Customer testimonials frequently highlight the transformative impact of incorporating metal honeycomb structures. From enhancing product longevity to adapting designs that meet future needs, the feedback reinforces a narrative of innovation driving tangible benefits. A wealth of case studies now exists, showcasing varied applications and demonstrating the widespread efficacy and adaptability of metal honeycomb technology. Advancements continue to be made in the production and application techniques of metal honeycombs, with ongoing research to explore new alloys and configurations that push the boundaries further. This relentless pursuit of innovation underscores the enduring importance of the metal honeycomb, ensuring its relevance and indispensability in both current and future landscapes. For stakeholders seeking to adopt or invest in metal honeycomb technology, understanding these distinctive advantages, backed by empirical evidence and authoritative testimonies, is paramount. This knowledge is not only a testament to the material's proven success but also a guide that will propel business innovations, ensuring sustained growth and environmental stewardship.

Manufacturers producing these metal honeycomb products adhere to stringent quality control measures, ensuring each product meets international standards. Expertise in alloy selection allows for customization, accommodating specific needs such as corrosion resistance or thermal conductivity. Trust in these products is further reinforced through certifications by recognized industry bodies, presenting an authoritative assurance of their performance and reliability. Customer testimonials frequently highlight the transformative impact of incorporating metal honeycomb structures. From enhancing product longevity to adapting designs that meet future needs, the feedback reinforces a narrative of innovation driving tangible benefits. A wealth of case studies now exists, showcasing varied applications and demonstrating the widespread efficacy and adaptability of metal honeycomb technology. Advancements continue to be made in the production and application techniques of metal honeycombs, with ongoing research to explore new alloys and configurations that push the boundaries further. This relentless pursuit of innovation underscores the enduring importance of the metal honeycomb, ensuring its relevance and indispensability in both current and future landscapes. For stakeholders seeking to adopt or invest in metal honeycomb technology, understanding these distinctive advantages, backed by empirical evidence and authoritative testimonies, is paramount. This knowledge is not only a testament to the material's proven success but also a guide that will propel business innovations, ensuring sustained growth and environmental stewardship.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025