- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 04:31

Back to list

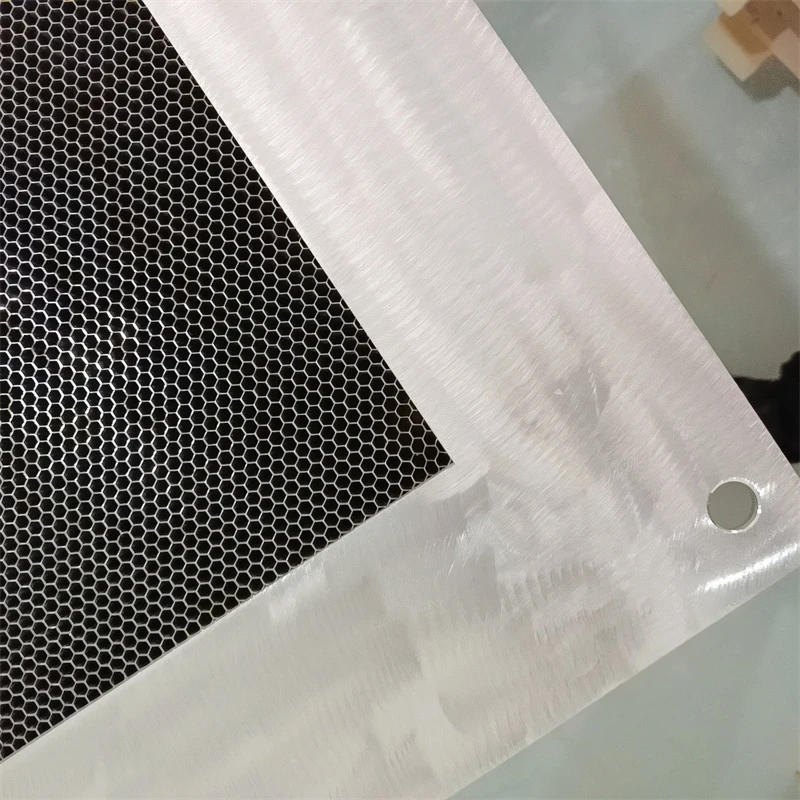

honeycomb seal

Metal honeycombs, known for their structural efficiency and unparalleled versatility, represent a cutting-edge innovation in the realm of advanced materials. These lightweight yet strong materials are gaining traction across various industries, from aerospace to architecture, driven by their unique ability to distribute stress evenly while minimizing material usage. As an objective witness to the evolving technological landscape, here's a professional insight into the distinct advantages and practical applications of metal honeycombs that underscore their growing authority in material science.

The architectural potential of metal honeycombs is equally significant. Architects and builders are increasingly turning to these materials to create structures that are not only aesthetically pleasing but also sustainable and cost-effective. The lightweight attribute of metal honeycombs allows for easier installation and reduces the need for heavy supporting frameworks, facilitating innovative designs that previously seemed untenable. Moreover, their excellent thermal insulation properties contribute to energy-efficient building solutions, aligning with global sustainability goals. References to metal honeycombs are also prevalent in the field of renewable energy. Wind turbine blades incorporate metal honeycombs to achieve an optimal balance between structural efficiency and weight reduction. This application enhances the performance and lifespan of turbines, thus boosting their economic viability and environmental benefits. Furthermore, solar panel manufacturers are exploring the integration of metal honeycombs to improve panel efficiency, demonstrating their versatility in supporting the green energy transition. From a product development perspective, metal honeycombs are manufactured using advanced fabrication techniques such as expansion or corrugation, which allow precise control over cell size and density according to specific application requirements. This customizable aspect empowers engineers and designers to tailor the material properties to meet stringent industry standards and achieve desired performance outcomes. In summation, the expertise surrounding metal honeycombs is built upon decades of rigorous research and real-world application, cementing their authority as a transformative material in various sectors. Their credibility is reinforced by data-driven performance metrics and a proven track record of enhancing safety, sustainability, and efficiency. As industries continue to evolve, the adoption of metal honeycombs is set to expand, driven by their compelling combination of expertise, functionality, and innovative application potential.

The architectural potential of metal honeycombs is equally significant. Architects and builders are increasingly turning to these materials to create structures that are not only aesthetically pleasing but also sustainable and cost-effective. The lightweight attribute of metal honeycombs allows for easier installation and reduces the need for heavy supporting frameworks, facilitating innovative designs that previously seemed untenable. Moreover, their excellent thermal insulation properties contribute to energy-efficient building solutions, aligning with global sustainability goals. References to metal honeycombs are also prevalent in the field of renewable energy. Wind turbine blades incorporate metal honeycombs to achieve an optimal balance between structural efficiency and weight reduction. This application enhances the performance and lifespan of turbines, thus boosting their economic viability and environmental benefits. Furthermore, solar panel manufacturers are exploring the integration of metal honeycombs to improve panel efficiency, demonstrating their versatility in supporting the green energy transition. From a product development perspective, metal honeycombs are manufactured using advanced fabrication techniques such as expansion or corrugation, which allow precise control over cell size and density according to specific application requirements. This customizable aspect empowers engineers and designers to tailor the material properties to meet stringent industry standards and achieve desired performance outcomes. In summation, the expertise surrounding metal honeycombs is built upon decades of rigorous research and real-world application, cementing their authority as a transformative material in various sectors. Their credibility is reinforced by data-driven performance metrics and a proven track record of enhancing safety, sustainability, and efficiency. As industries continue to evolve, the adoption of metal honeycombs is set to expand, driven by their compelling combination of expertise, functionality, and innovative application potential.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025