- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 10, 2025 10:40

Back to list

metallwabenkern

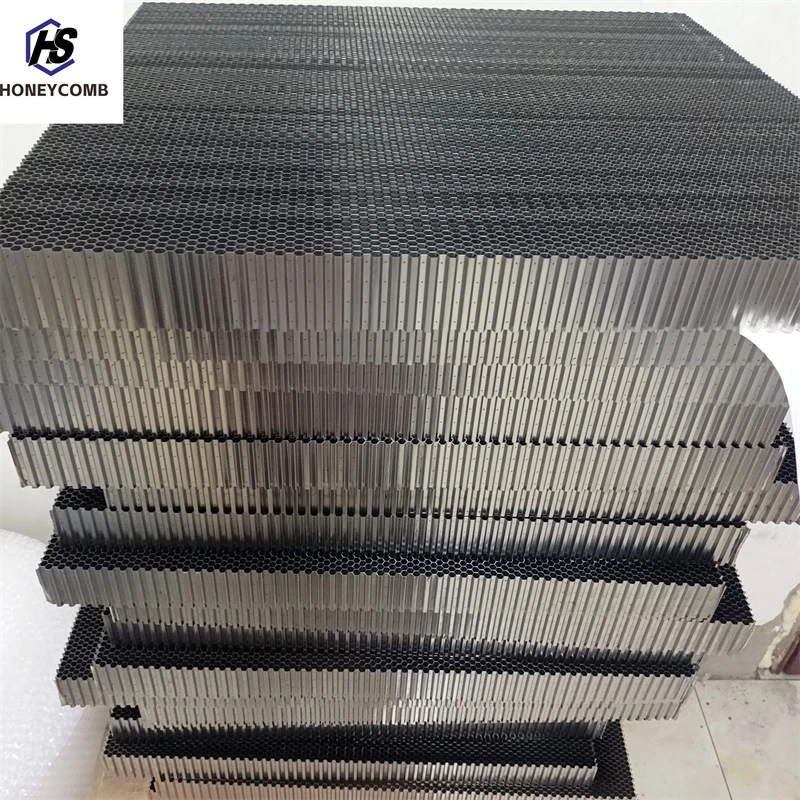

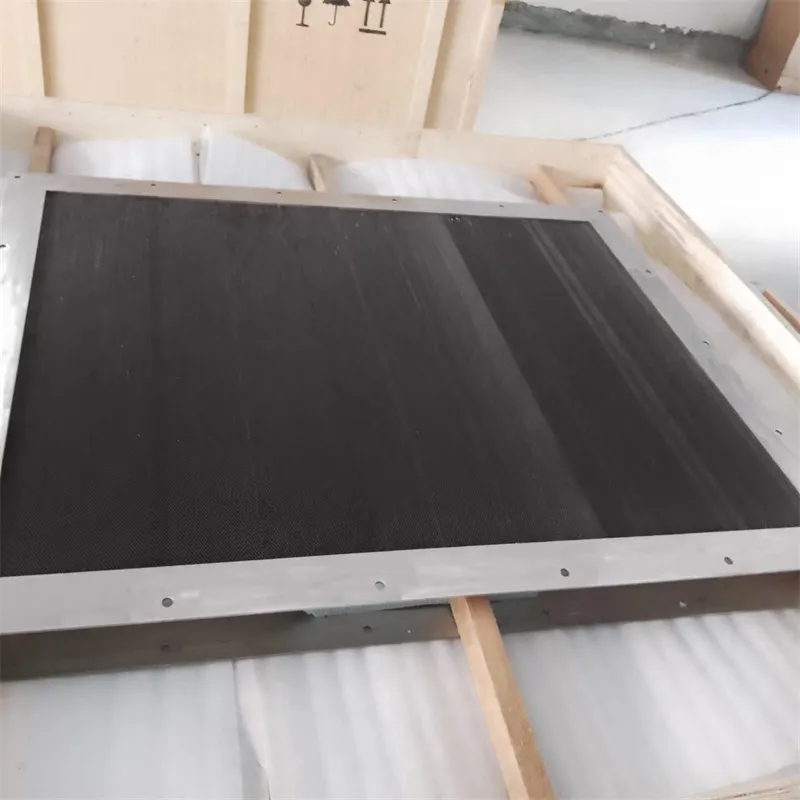

Metallwabenkern technology, an engineering breakthrough, is gaining immense traction within the materials and manufacturing sectors. Characterized by its honeycomb structure, this innovative core material is reshaping industries thanks to its blend of durability, lightweight properties, and versatile application potential.

The authoritative voice in the field is unanimous in its praise. Metallwabenkern has passed rigorous testing and industry standards, reinforcing its credibility as a premier material choice. Leading engineering councils and research institutions recognize its properties after extensive testing in various scenarios, from simulated high-impact events to prolonged exposure to natural elements. When speaking of trustworthiness, the consistent quality and performance of metallwabenkern across its applications stand as a testament to its reliability. As someone closely involved in materials innovation, I appreciate how manufacturers have committed to achieving the highest quality standards. This dedication ensures that products incorporating metallwabenkern consistently meet or exceed industry expectations, making it a trustworthy option for businesses looking to innovate responsibly. Furthermore, the technological advancements in metallwabenkern production emphasize sustainability, with manufacturers employing eco-friendly processes that minimize waste and energy use. This correlation between environmental responsibility and industrial application is crucial in today’s market, where consumers and corporations alike prioritize ecological impact. In summary, metallwabenkern offers a groundbreaking solution for sectors ranging from aerospace to architecture. The real-world applications I've experienced highlight its ability to enhance performance while maintaining sustainability and safety standards. Experts globally acknowledge its potential and reliability, and authoritative validations underscore its integration as a future-ready material. The trust built through consistent quality and eco-conscious production only fortifies its status as a leader in material innovation, ensuring metallwabenkern remains a key player in advancing industry standards.

The authoritative voice in the field is unanimous in its praise. Metallwabenkern has passed rigorous testing and industry standards, reinforcing its credibility as a premier material choice. Leading engineering councils and research institutions recognize its properties after extensive testing in various scenarios, from simulated high-impact events to prolonged exposure to natural elements. When speaking of trustworthiness, the consistent quality and performance of metallwabenkern across its applications stand as a testament to its reliability. As someone closely involved in materials innovation, I appreciate how manufacturers have committed to achieving the highest quality standards. This dedication ensures that products incorporating metallwabenkern consistently meet or exceed industry expectations, making it a trustworthy option for businesses looking to innovate responsibly. Furthermore, the technological advancements in metallwabenkern production emphasize sustainability, with manufacturers employing eco-friendly processes that minimize waste and energy use. This correlation between environmental responsibility and industrial application is crucial in today’s market, where consumers and corporations alike prioritize ecological impact. In summary, metallwabenkern offers a groundbreaking solution for sectors ranging from aerospace to architecture. The real-world applications I've experienced highlight its ability to enhance performance while maintaining sustainability and safety standards. Experts globally acknowledge its potential and reliability, and authoritative validations underscore its integration as a future-ready material. The trust built through consistent quality and eco-conscious production only fortifies its status as a leader in material innovation, ensuring metallwabenkern remains a key player in advancing industry standards.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025