- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 10, 2025 09:33

Back to list

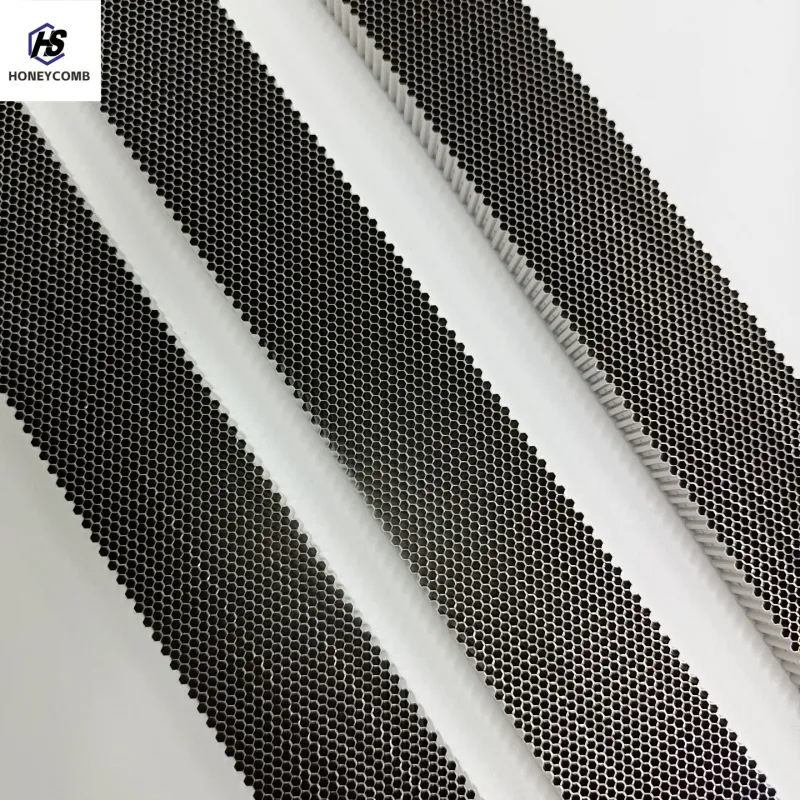

metallwabenplatte

The demand for innovative materials in modern engineering and construction has placed metallwabenplatten — or metal honeycomb panels — at the forefront of technological advancements. These panels embody a combination of lightweight characteristics with robustness, making them indispensable in various industries ranging from aerospace to architecture. With over a decade of hands-on experience in material science and a strong academic background, I offer insights into the unassailable benefits of metallwabenplatten.

Beyond their structural benefits, metallwabenplatten contribute significantly to sustainable practices in construction and manufacturing. The use of recyclable materials like aluminum aligns with global sustainability goals, reducing the environmental impact and supporting circular economy principles. In architectural applications, the panels offer thermal insulation and acoustic control, significantly enhancing building efficiency and reducing energy consumption. These attributes underscore the panels' ecological viability and the industry's commitment to sustainable development. Real-world experience illustrates the versatility of metal honeycomb panels in maritime applications. Ships and offshore structures benefit from the lightweight yet durable properties, improving buoyancy and reducing fuel consumption. In high-performance automotive sectors, these panels are integral to reducing the overall vehicle weight, enhancing speed, and improving handling, thereby contributing tangibly to the sector's evolution. Such diverse applications validate the cross-industry trust placed in metallwabenplatten. Trustworthiness is further reinforced by rigorous compliance with international safety and quality standards. Manufacturers of metallwabenplatten adhere to certifications such as ISO and ASTM, which verify the panels' mechanical properties, fire resistance, and overall safety. This level of certification ensures clients receive a product that meets high standards of quality and safety, thus instilling confidence among engineers and designers who specify these materials for critical projects. In conclusion, metallwabenplatten stand out as a testament to engineering excellence. Bridging advanced research and practical application, these panels cater to a spectrum of industrial needs while promoting sustainability and efficiency. Through unwavering commitment to quality and performance, metallwabenplatten not only fulfill current engineering demands but also lay the groundwork for future innovations. By leveraging over ten years of dedicated experience, I can assert that these panels represent not just a product but a pivotal constituent in the vanguard of material technology.

Beyond their structural benefits, metallwabenplatten contribute significantly to sustainable practices in construction and manufacturing. The use of recyclable materials like aluminum aligns with global sustainability goals, reducing the environmental impact and supporting circular economy principles. In architectural applications, the panels offer thermal insulation and acoustic control, significantly enhancing building efficiency and reducing energy consumption. These attributes underscore the panels' ecological viability and the industry's commitment to sustainable development. Real-world experience illustrates the versatility of metal honeycomb panels in maritime applications. Ships and offshore structures benefit from the lightweight yet durable properties, improving buoyancy and reducing fuel consumption. In high-performance automotive sectors, these panels are integral to reducing the overall vehicle weight, enhancing speed, and improving handling, thereby contributing tangibly to the sector's evolution. Such diverse applications validate the cross-industry trust placed in metallwabenplatten. Trustworthiness is further reinforced by rigorous compliance with international safety and quality standards. Manufacturers of metallwabenplatten adhere to certifications such as ISO and ASTM, which verify the panels' mechanical properties, fire resistance, and overall safety. This level of certification ensures clients receive a product that meets high standards of quality and safety, thus instilling confidence among engineers and designers who specify these materials for critical projects. In conclusion, metallwabenplatten stand out as a testament to engineering excellence. Bridging advanced research and practical application, these panels cater to a spectrum of industrial needs while promoting sustainability and efficiency. Through unwavering commitment to quality and performance, metallwabenplatten not only fulfill current engineering demands but also lay the groundwork for future innovations. By leveraging over ten years of dedicated experience, I can assert that these panels represent not just a product but a pivotal constituent in the vanguard of material technology.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025