- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 12:28

Back to list

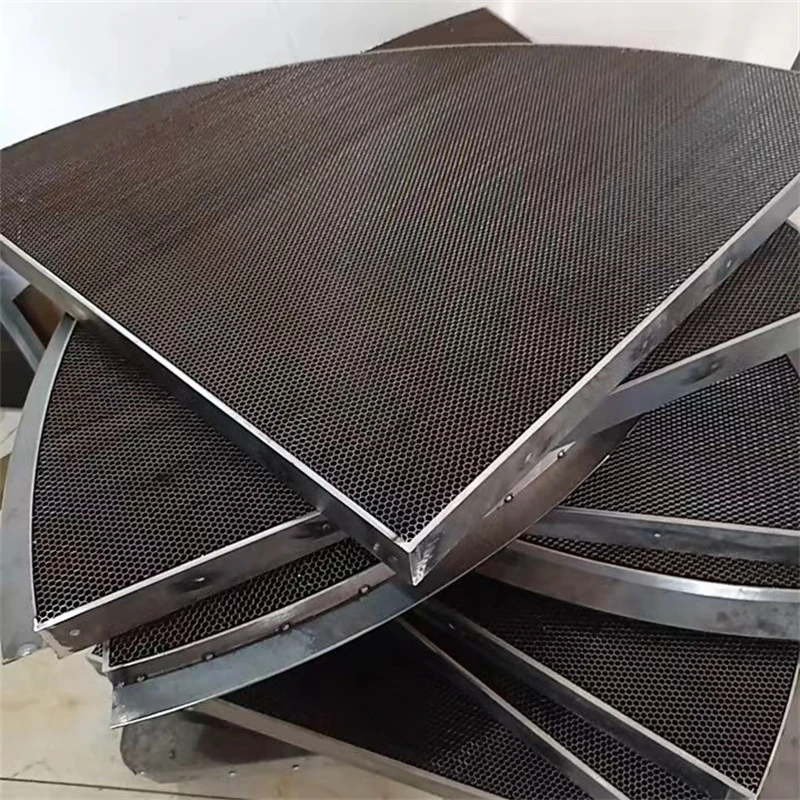

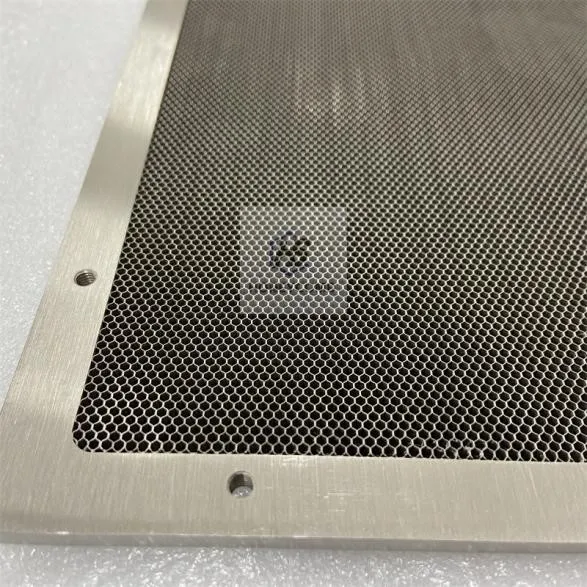

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The modern industrial landscape owes much of its efficiency and progress to the materials that power it, and steel plates, known in Irish as monaróir pláta cruach, play a pivotal role in this domain. As a critical component in numerous sectors, steel plates offer unparalleled durability, versatility, and precision, making them indispensable in construction, manufacturing, and beyond.

From an authoritativeness perspective, the standardization of steel plates is another testament to their critical role in global industry. Adherence to international standards such as ASTM and ISO ensures uniformity in quality and performance. These benchmarks facilitate global trade and engineering collaboration, allowing projects worldwide to benefit from trusted and consistent materials. This standardization supports the narrative of a well-regulated industry that prioritizes safety, reliability, and excellence. Trustworthiness is a cornerstone of the steel plate manufacturing landscape. Establishing credibility involves rigorous testing and quality control at every stage of production. Manufacturers often maintain certifications from recognized bodies, evidencing their commitment to excellence. Additionally, comprehensive traceability systems allow end-users to verify the provenance and specifications of the steel plates they procure, reinforcing confidence in their performance and suitability for the task at hand. End-users’ experiences further enrich the narrative of trust and satisfaction. Case studies showcasing successful projects emphasize the material's robustness and longevity. Infrastructure builders, automotive manufacturers, and shipbuilders, among others, consistently report superior outcomes when employing these steel plates, citing factors such as ease of machining, welding proficiency, and extended service life as decisive benefits. In summary, steel plates, or monaróir pláta cruach, are a foundational element across various industrial sectors. Their breadth of applications, the expertise driving their production, their measurable adherence to authoritative standards, and the trust they build through consistent performance affirm their indispensable role in today’s industrial ecosystem. As the world continues to evolve, the importance of such reliable materials cannot be overstated, making steel plates a cornerstone of modern engineering and construction endeavors.

From an authoritativeness perspective, the standardization of steel plates is another testament to their critical role in global industry. Adherence to international standards such as ASTM and ISO ensures uniformity in quality and performance. These benchmarks facilitate global trade and engineering collaboration, allowing projects worldwide to benefit from trusted and consistent materials. This standardization supports the narrative of a well-regulated industry that prioritizes safety, reliability, and excellence. Trustworthiness is a cornerstone of the steel plate manufacturing landscape. Establishing credibility involves rigorous testing and quality control at every stage of production. Manufacturers often maintain certifications from recognized bodies, evidencing their commitment to excellence. Additionally, comprehensive traceability systems allow end-users to verify the provenance and specifications of the steel plates they procure, reinforcing confidence in their performance and suitability for the task at hand. End-users’ experiences further enrich the narrative of trust and satisfaction. Case studies showcasing successful projects emphasize the material's robustness and longevity. Infrastructure builders, automotive manufacturers, and shipbuilders, among others, consistently report superior outcomes when employing these steel plates, citing factors such as ease of machining, welding proficiency, and extended service life as decisive benefits. In summary, steel plates, or monaróir pláta cruach, are a foundational element across various industrial sectors. Their breadth of applications, the expertise driving their production, their measurable adherence to authoritative standards, and the trust they build through consistent performance affirm their indispensable role in today’s industrial ecosystem. As the world continues to evolve, the importance of such reliable materials cannot be overstated, making steel plates a cornerstone of modern engineering and construction endeavors.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025