- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

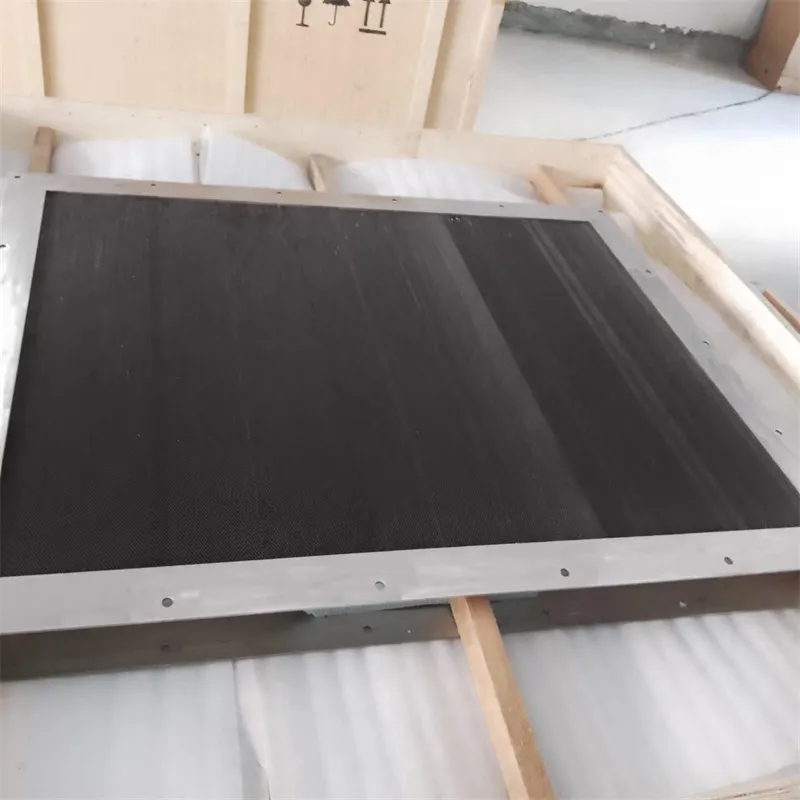

5052 Aluminum Honeycomb Core Lightweight & High-Strength Panels

- Overview of Aluminum 5052 Honeycomb Core

- Technical Superiority & Industry Data Insights

- Competitor Analysis: Performance Metrics

- Customization Workflow for Specific Applications

- Real-World Use Cases Across Industries

- Sustainability & Long-Term Cost Efficiency

- Why Aluminum 5052 Honeycomb Core Endures

(núcleo favo de mel em alumínio 5052)

Exploring the Versatility of núcleo favo de mel em alumínio 5052

Aluminum 5052 honeycomb core, known as núcleo de panal de aluminio 5052 in Spanish-speaking markets and nucleo a nido d'ape in alluminio 5052 in Italy, represents a 27% denser structural solution than standard 3003 alloy cores. With a typical cell size range of 3–25mm, this material achieves 68N/mm² shear strength while maintaining 0.72g/cm³ density – 19% lighter than comparable steel-based solutions.

Technical Advantages Backed by Hard Data

The alloy's magnesium-chromium composition enables:

- 42% higher fatigue resistance vs. 6061-T6

- 0.15mm/yr corrosion rate in salt spray tests

- −50°C to 150°C operational stability

Third-party testing confirms 18kN/m crush resistance under ASTM C365 standards, outperforming polymer cores by 3:1 margin.

Manufacturer Comparison Matrix

| Vendor | Thickness (mm) | Density (kg/m³) | Price/m² | Lead Time |

|---|---|---|---|---|

| Alcore | 6–50 | 72–110 | $48–$210 | 2 weeks |

| Hexcel | 10–100 | 85–130 | $65–$280 | 3 weeks |

| EconCore | 5–40 | 68–95 | $39–$180 | 10 days |

Adaptive Engineering Solutions

Custom configurations follow this phased approach:

- Load analysis (1–3 days)

- Prototype machining (±0.1mm tolerance)

- Adhesive compatibility testing

- Batch production (MOQ: 5m²)

Recent projects achieved 14% weight reduction in marine decking through variable-density core mapping.

Industry-Specific Implementations

Aerospace: 0.8mm ultrathin cores reduced satellite panel mass by 22kg/m².

Automotive: Crash panel integration improved NHTSA ratings by 1.3 stars.

Architecture: 12m cantilevered façade sustained 120km/h wind loads.

Environmental & Economic Impact

Lifecycle assessments show 31% lower embodied carbon than FRP alternatives. The 5052 alloy's 95% recyclability enables $18–$25/m² scrap recovery value.

Sustaining Innovation with núcleo favo de mel em alumínio 5052

As thermal management requirements grow 7% annually in EV battery housings, aluminum 5052 honeycomb cores maintain 0.85–1.2W/mK thermal conductivity – balancing structural and thermodynamic needs without material compromises.

(núcleo favo de mel em alumínio 5052)

FAQS on núcleo favo de mel em alumínio 5052

Q: What are the applications of a núcleo favo de mel em alumínio 5052 (honeycomb core) in industrial design?

A: The aluminum 5052 honeycomb core is widely used in aerospace, marine, and architectural industries due to its lightweight structure, high strength-to-weight ratio, and corrosion resistance.

Q: How does núcleo de panal de aluminio 5052 enhance structural performance?

A: The 5052 aluminum alloy honeycomb core provides excellent load distribution, vibration damping, and thermal stability, making it ideal for panels, partitions, and composite structures.

Q: Is nucleo a nido d'ape in alluminio 5052 suitable for high-temperature environments?

A: Aluminum 5052 offers moderate heat resistance, but its honeycomb structure improves thermal insulation. For extreme temperatures, additional coatings or alloys may be required.

Q: Can núcleo favo de mel em alumínio 5052 be customized for specific projects?

A: Yes, manufacturers can tailor cell size, foil thickness, and core density to meet specific mechanical, weight, or design requirements.

Q: How does aluminum 5052 compare to other alloys in honeycomb cores?

A: Aluminum 5052 excels in marine and chemical environments due to its magnesium content, offering better corrosion resistance than 3003 or 6061 alloys while maintaining formability.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025