- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 11, 2025 09:19

Back to list

núcleo de nido de abeja de aluminio celular

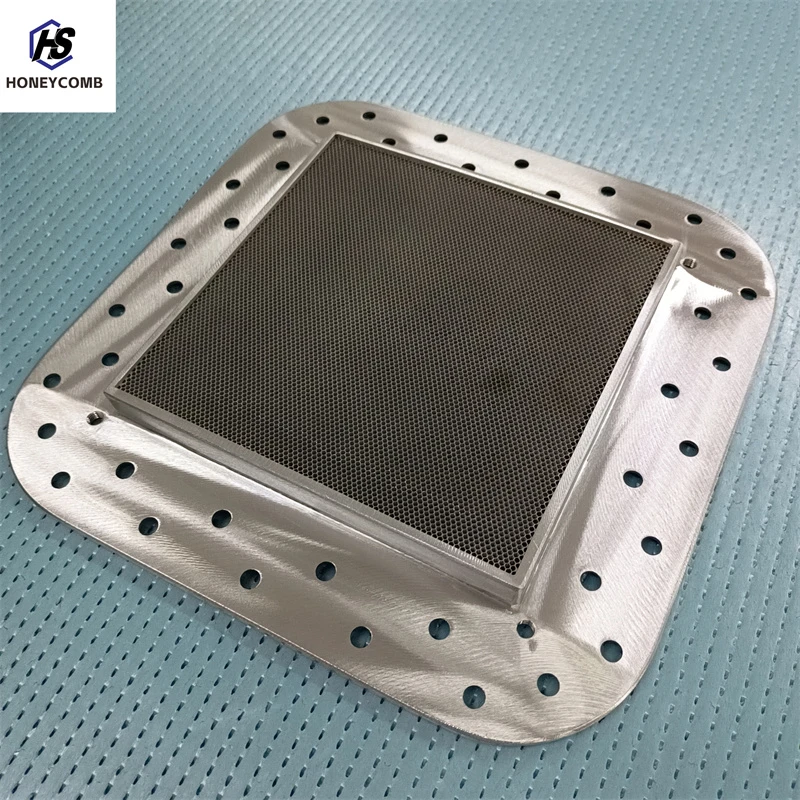

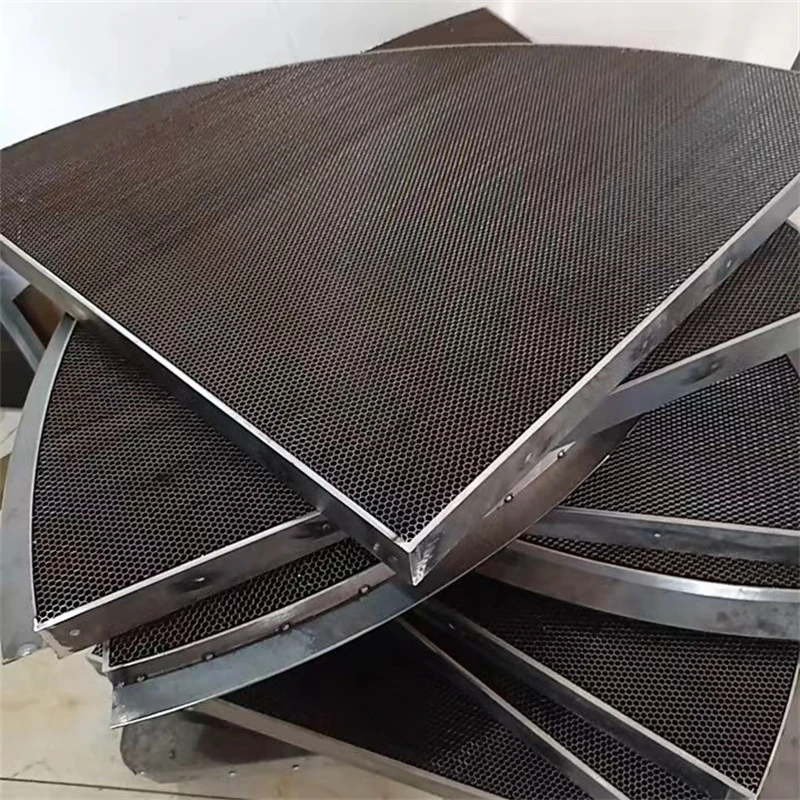

Aluminum cellular honeycomb core is revolutionizing industries with its exceptional properties and versatile applications. This innovative material, known for its lightweight yet rigid structure, is becoming increasingly prominent in aerospace, automotive, and construction sectors. Firms around the globe are leveraging its benefits to enhance product performance and sustainability.

Professionals in the marine industry are also increasingly relying on aluminum cellular honeycomb core for shipbuilding. Its resistance to harsh marine environments, coupled with the ability to float, makes it an excellent material for boat hulls and decks. The result is robust vessels that require less energy for propulsion, thus reducing operational costs and enhancing environmental sustainability. Marine engineers laud these advancements for enhancing safety and efficiency in vessel design. From a technical standpoint, the manufacture of aluminum cellular honeycomb core involves an intricate process, ensuring uniformity and stability in its hexagonal structure. Engineers and materials scientists continuously refine these processes to further enhance the material's capabilities. These advancements ensure that aluminum cellular honeycomb core remains at the cutting edge of material technology, offering reliable solutions across various demanding applications. Supply chain experts emphasize the scalability of this material. Given its increasing demand, it is imperative to have robust supply chain strategies in place. Manufacturers adeptly manage logistics and production challenges to meet global demands without compromising quality. A reliable supply chain enhances trustworthiness, ensuring that industries can depend on a consistent supply of high-quality aluminum cellular honeycomb core. In conclusion, aluminum cellular honeycomb core represents a breakthrough in material science, offering unmatched benefits across multiple industries. Its ability to improve efficiency, safety, and sustainability is backed by expert research and real-world applications. Industries utilizing this innovative material report enhanced performance, reduced costs, and significant advancements in design and functionality. As technology continues to evolve, the trusted applicability and authority of aluminum cellular honeycomb core will undoubtedly expand, solidifying its position as a critical component in engineering and manufacturing innovation.

Professionals in the marine industry are also increasingly relying on aluminum cellular honeycomb core for shipbuilding. Its resistance to harsh marine environments, coupled with the ability to float, makes it an excellent material for boat hulls and decks. The result is robust vessels that require less energy for propulsion, thus reducing operational costs and enhancing environmental sustainability. Marine engineers laud these advancements for enhancing safety and efficiency in vessel design. From a technical standpoint, the manufacture of aluminum cellular honeycomb core involves an intricate process, ensuring uniformity and stability in its hexagonal structure. Engineers and materials scientists continuously refine these processes to further enhance the material's capabilities. These advancements ensure that aluminum cellular honeycomb core remains at the cutting edge of material technology, offering reliable solutions across various demanding applications. Supply chain experts emphasize the scalability of this material. Given its increasing demand, it is imperative to have robust supply chain strategies in place. Manufacturers adeptly manage logistics and production challenges to meet global demands without compromising quality. A reliable supply chain enhances trustworthiness, ensuring that industries can depend on a consistent supply of high-quality aluminum cellular honeycomb core. In conclusion, aluminum cellular honeycomb core represents a breakthrough in material science, offering unmatched benefits across multiple industries. Its ability to improve efficiency, safety, and sustainability is backed by expert research and real-world applications. Industries utilizing this innovative material report enhanced performance, reduced costs, and significant advancements in design and functionality. As technology continues to evolve, the trusted applicability and authority of aluminum cellular honeycomb core will undoubtedly expand, solidifying its position as a critical component in engineering and manufacturing innovation.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025