- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 21:35

Back to list

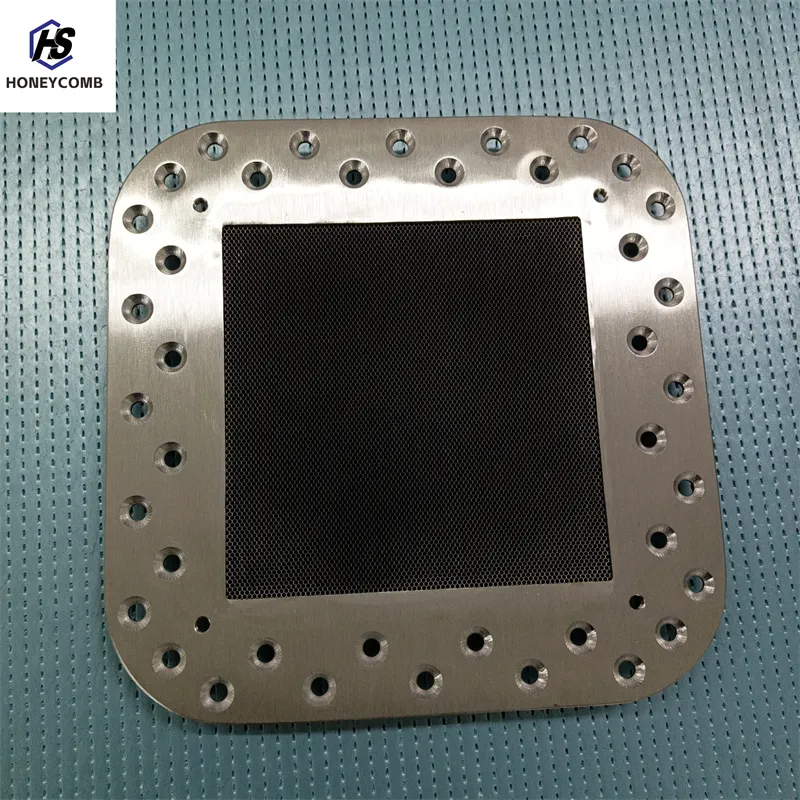

núcleo de panal metálico

Metallic honeycomb core technology has become essential in industries where strength, light weight, and energy absorption are critical. This revolutionary product is redefining how engineers and designers approach structures in sectors like aerospace, automotive, and construction. The intrinsic properties of a honeycomb structure, characterized by its hexagonal cells, provide an outstanding balance between structural efficiency and reduced material usage. Drawing upon decades of scientific expertise and hands-on experience, let's delve into the advantages and applications of metallic honeycomb cores to reveal why they stand at the forefront of modern engineering solutions.

In terms of manufacturing expertise, the production of metallic honeycomb cores involves meticulous processes to ensure quality and precision. Advanced techniques like precision laser cutting and adhesive bonding are employed to maintain the geometric accuracy and mechanical integrity of the honeycomb meshes. This high level of manufacturing expertise underscores the trustworthiness of these products in critical applications, allowing industries to innovate without compromising safety or reliability. Trust in metallic honeycomb technology is bolstered by its authoritative adoption across various prestigious projects and industries. Renowned engineering firms and aerospace manufacturers continually validate the technology through rigorous testing, cementing its reputation for dependability and performance. Furthermore, the continuous collaboration between researchers and industry leaders drives the evolution of this technology, ensuring its alignment with modern engineering challenges. Sustainability is also a critical consideration in the use of metallic honeycomb cores. Their lightweight nature contributes to energy efficiency and reduces the carbon footprint of transportation vehicles and buildings. This aligns with global trends towards sustainable engineering practices, adding an ecological dimension to their technical advantages. In essence, the metallic honeycomb core represents a perfect fusion of nature-inspired engineering and cutting-edge technology. Its broad application scope, coupled with its proven performance in demanding environments, highlights its value as an indispensable component in today's engineering solutions. By harnessing the expertise of industry leaders and continuously advancing the technology, metallic honeycomb cores are positioned to shape the future of structural design, rendering them a trusted ally in the pursuit of innovation and sustainability.

In terms of manufacturing expertise, the production of metallic honeycomb cores involves meticulous processes to ensure quality and precision. Advanced techniques like precision laser cutting and adhesive bonding are employed to maintain the geometric accuracy and mechanical integrity of the honeycomb meshes. This high level of manufacturing expertise underscores the trustworthiness of these products in critical applications, allowing industries to innovate without compromising safety or reliability. Trust in metallic honeycomb technology is bolstered by its authoritative adoption across various prestigious projects and industries. Renowned engineering firms and aerospace manufacturers continually validate the technology through rigorous testing, cementing its reputation for dependability and performance. Furthermore, the continuous collaboration between researchers and industry leaders drives the evolution of this technology, ensuring its alignment with modern engineering challenges. Sustainability is also a critical consideration in the use of metallic honeycomb cores. Their lightweight nature contributes to energy efficiency and reduces the carbon footprint of transportation vehicles and buildings. This aligns with global trends towards sustainable engineering practices, adding an ecological dimension to their technical advantages. In essence, the metallic honeycomb core represents a perfect fusion of nature-inspired engineering and cutting-edge technology. Its broad application scope, coupled with its proven performance in demanding environments, highlights its value as an indispensable component in today's engineering solutions. By harnessing the expertise of industry leaders and continuously advancing the technology, metallic honeycomb cores are positioned to shape the future of structural design, rendering them a trusted ally in the pursuit of innovation and sustainability.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025