- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 14:10

Back to list

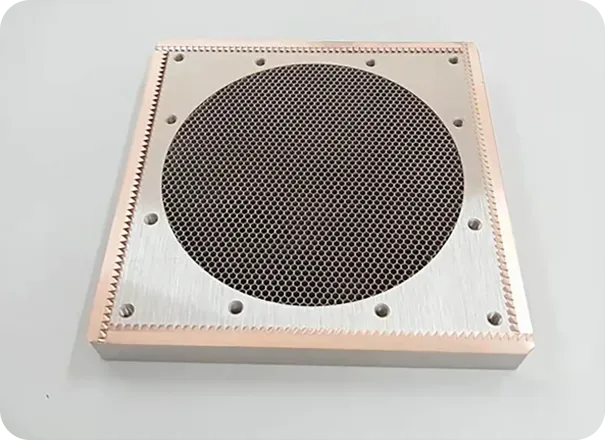

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Aluminum honeycomb panels have revolutionized industries from construction to aerospace due to their innovative design and unparalleled functionality. These panels, known for their high strength-to-weight ratio, are engineered using a honeycomb structure fabricated from aluminum, a design that mimics the perfection of nature. By incorporating this design into practical applications, manufacturers have succeeded in enhancing the performance and efficiency of countless products.

The versatility of aluminum honeycomb panels extends beyond aerospace and construction. In the automotive industry, these materials are used to produce components that contribute to fuel efficiency and safety. By reducing the weight of vehicles, manufacturers can improve fuel consumption and decrease emissions, aligning with stringent environmental regulations. Furthermore, the crash-resistant nature of the panels enhances vehicular safety, offering robust protection in the event of accidents. In the realm of interior design, aluminum honeycomb panels offer aesthetic and functional advantages. They are used to create modern furniture, displays, and room partitions, thanks to their sleek appearance and durability. Designers appreciate the adaptability of these panels, which can be coated with different finishes to achieve various looks, satisfying diverse stylistic preferences. The credibility and authority of aluminum honeycomb panel manufacturers are established through years of research and development, customer feedback, and continuous improvement practices. Companies leading in this domain invest heavily in R&D, staying at the forefront of innovation in material sciences. They have acquired certifications from international standards organizations, further enhancing their trustworthiness in the market. Purchasing from reputable suppliers ensures that businesses and consumers receive panels that conform to the high standards expected in demanding applications. Customer service excellence, warranties, and post-purchase support are additional markers of a trusted brand, providing peace of mind alongside the technical advantages of the panels. The integration of aluminum honeycomb panels into a myriad of applications highlights not only their practicality but also their potential to redefine industry standards. Their unique attributes make them indispensable components in the quest for performance, sustainability, and innovation. As industries continue to evolve, embracing these advanced materials will be a pivotal step in achieving superior outcomes and efficiency.

The versatility of aluminum honeycomb panels extends beyond aerospace and construction. In the automotive industry, these materials are used to produce components that contribute to fuel efficiency and safety. By reducing the weight of vehicles, manufacturers can improve fuel consumption and decrease emissions, aligning with stringent environmental regulations. Furthermore, the crash-resistant nature of the panels enhances vehicular safety, offering robust protection in the event of accidents. In the realm of interior design, aluminum honeycomb panels offer aesthetic and functional advantages. They are used to create modern furniture, displays, and room partitions, thanks to their sleek appearance and durability. Designers appreciate the adaptability of these panels, which can be coated with different finishes to achieve various looks, satisfying diverse stylistic preferences. The credibility and authority of aluminum honeycomb panel manufacturers are established through years of research and development, customer feedback, and continuous improvement practices. Companies leading in this domain invest heavily in R&D, staying at the forefront of innovation in material sciences. They have acquired certifications from international standards organizations, further enhancing their trustworthiness in the market. Purchasing from reputable suppliers ensures that businesses and consumers receive panels that conform to the high standards expected in demanding applications. Customer service excellence, warranties, and post-purchase support are additional markers of a trusted brand, providing peace of mind alongside the technical advantages of the panels. The integration of aluminum honeycomb panels into a myriad of applications highlights not only their practicality but also their potential to redefine industry standards. Their unique attributes make them indispensable components in the quest for performance, sustainability, and innovation. As industries continue to evolve, embracing these advanced materials will be a pivotal step in achieving superior outcomes and efficiency.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025