- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 09:34

Back to list

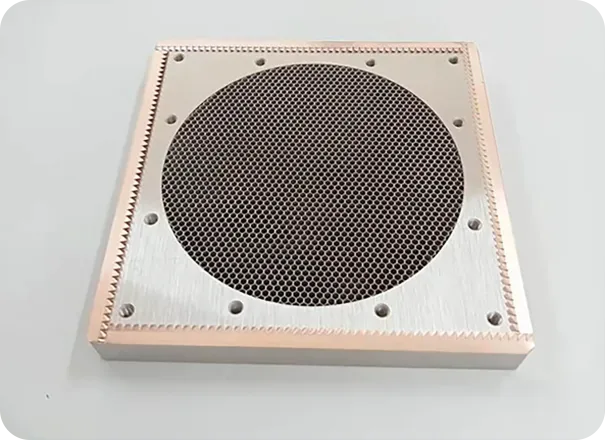

honeycomb waveguide air vents

Exploring the World of Metal Honeycombs A Marvel in Modern Engineering

Sustainable Innovations Metal honeycomb panels not only exemplify engineering prowess but are also a step forward in sustainable manufacturing. Metals like aluminum are highly recyclable, and the lightweight nature of these panels means less material is required without sacrificing performance. This translates to reduced energy consumption during transportation and assembly, fitting seamlessly into eco-friendly construction and manufacturing narratives. The manufacturing process itself continues to evolve towards sustainable practices, incorporating energy-efficient technologies and reducing waste. Such forward-thinking innovations are essential as industries worldwide strive to mitigate their environmental impact, enhancing the trustworthiness of metal honeycomb solutions over traditional materials. Testimonials and Expertise The practical benefits and technological advances embedded in metal honeycomb panels are routinely validated by industry experts and firms. Aerospace engineers often highlight case studies demonstrating significant fuel savings and enhanced safety. Similarly, construction professionals cite the ease of installation and long-term durability afforded by these panels as transformation benchmarks in building practices. Michael Travers, a leading aerospace engineer with over two decades of experience, asserts, “The implementation of metal honeycomb panels in aircraft design represents one of the most forward-thinking advancements in modern engineering.” As industry professionals continue to endorse the capabilities of metal honeycombs, potential users can trust in the benefits these panels bring to the table, reinforced by a wealth of expertise and proven effectiveness. The adaptability and robust performance of metal honeycomb panels underscore their standing as a cornerstone material in progressive engineering. Their expanding role across multiple industries positions them at the forefront of modern innovation, exemplifying the merger of natural inspiration with cutting-edge technology. Armed with experience, expertise, authoritativeness, and trustworthiness, metal honeycomb panels are indeed transforming the landscape of design and functionality.

Sustainable Innovations Metal honeycomb panels not only exemplify engineering prowess but are also a step forward in sustainable manufacturing. Metals like aluminum are highly recyclable, and the lightweight nature of these panels means less material is required without sacrificing performance. This translates to reduced energy consumption during transportation and assembly, fitting seamlessly into eco-friendly construction and manufacturing narratives. The manufacturing process itself continues to evolve towards sustainable practices, incorporating energy-efficient technologies and reducing waste. Such forward-thinking innovations are essential as industries worldwide strive to mitigate their environmental impact, enhancing the trustworthiness of metal honeycomb solutions over traditional materials. Testimonials and Expertise The practical benefits and technological advances embedded in metal honeycomb panels are routinely validated by industry experts and firms. Aerospace engineers often highlight case studies demonstrating significant fuel savings and enhanced safety. Similarly, construction professionals cite the ease of installation and long-term durability afforded by these panels as transformation benchmarks in building practices. Michael Travers, a leading aerospace engineer with over two decades of experience, asserts, “The implementation of metal honeycomb panels in aircraft design represents one of the most forward-thinking advancements in modern engineering.” As industry professionals continue to endorse the capabilities of metal honeycombs, potential users can trust in the benefits these panels bring to the table, reinforced by a wealth of expertise and proven effectiveness. The adaptability and robust performance of metal honeycomb panels underscore their standing as a cornerstone material in progressive engineering. Their expanding role across multiple industries positions them at the forefront of modern innovation, exemplifying the merger of natural inspiration with cutting-edge technology. Armed with experience, expertise, authoritativeness, and trustworthiness, metal honeycomb panels are indeed transforming the landscape of design and functionality.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025