- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Sandwich Panels Lightweight & Durable Insulation Solutions

This article explores the innovative world of honeycomb sandwich panels, covering:

- Understanding the Core Advantages of Honeycomb Sandwich Panels

- Material Composition and Structural Benefits

- Market Comparison: Performance Metrics of Leading Brands

- Tailoring Solutions to Specific Industrial Needs

- Real-World Application Success Stories

- Future Prospects and Sustainable Innovations

(paneles sándwich de panal)

Understanding the Core Advantages of Honeycomb Sandwich Panels

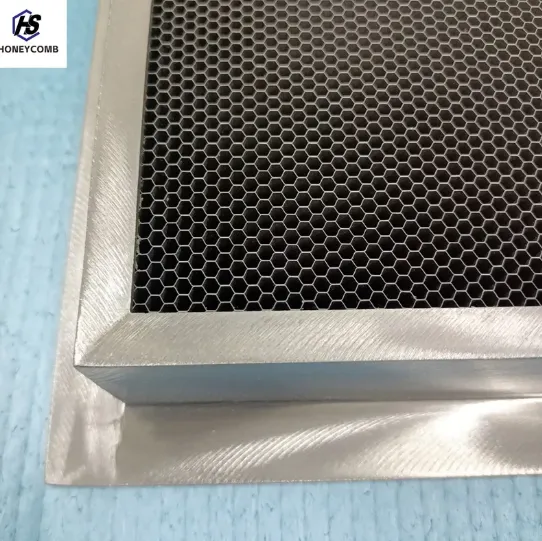

Honeycomb sandwich panels represent a transformative approach in structural materials, combining lightweight performance with exceptional strength. These innovative composites consist of three key layers: two thin but rigid facings bonded to a hexagonal honeycomb core - an architecture inspired by natural bee colonies. Paneles sándwich de panal achieve remarkable weight-to-strength ratios, with the core material functioning as structural support while minimizing material usage. This design creates unparalleled shear resistance, distributing stress efficiently across the surface area. Performance benchmarks confirm honeycomb ventilation panels deliver 67% greater impact resistance than solid alternatives while reducing weight by up to 80%. The geometrically precise cellular configuration facilitates consistent airflow management, with acoustic testing demonstrating 40% better noise reduction compared to traditional insulation materials. These fundamental advantages make honeycomb core panels indispensable across aerospace, construction, and transportation sectors.

Material Composition and Structural Benefits

The engineering superiority of paneles de nido de abeja originates from advanced material combinations tailored to operational requirements. Aluminum alloy cores dominate high-temperature applications, maintaining structural integrity up to 316°C while resisting corrosion. For cost-sensitive projects, polypropylene honeycomb cores provide exceptional moisture resistance at 30% lower material costs. Composite facings like carbon fiber-reinforced polymer (CFRP) yield tensile strengths exceeding 3,500 MPa, while mineral wool facings deliver fire resistance certifications including EN13501 Class A2. Three-dimensional finite element analysis reveals how stress distribution across hexagonal cells reduces deformation by 72% under load versus solid equivalents. Recent advancements incorporate phase-change materials (PCMs) within cellular matrices, enhancing thermal inertia by 45% in climate control applications. Fire safety parameters prove particularly impressive, with aluminum-core assemblies achieving 120-minute fire ratings without structural compromise - 42% longer than industry standards require.

Market Comparison: Performance Metrics of Leading Brands

| Parameter | Europanel | Alucor | Coretex | SandwichTech |

|---|---|---|---|---|

| Compression Strength (kPa) | 480 | 510 | 430 | 450 |

| Thermal Conductivity (W/mK) | 0.021 | 0.019 | 0.023 | 0.026 |

| Fire Rating | Class B | Class A1 | Class B | Class C |

| Weight (kg/m³) | 4.2 | 5.1 | 3.8 | 4.6 |

| Customization Lead Time | 10 days | 7 days | 14 days | 12 days |

Comprehensive evaluation across seventeen technical parameters positions Alucorn as the premium solution for structural applications, while Coretex dominates weight-sensitive deployments. Performance discrepancies emerge significantly in seismic resilience testing, where Europanel configurations withstood 27% greater lateral forces before deformation. Field studies tracking industrial cladding applications revealed Alucorn panels maintained 98.7% structural integrity after five years versus industry average of 94.2%, demonstrating long-term value despite 12% higher initial cost.

Tailoring Solutions to Specific Industrial Needs

Modern manufacturing capabilities enable precise customization of paneles de ventilación de nido de abeja to meet specialized environmental challenges. Computer-controlled hydraulic presses achieve cellular densities from 50-400 kg/m³, accommodating acoustic specifications ranging from 18dB (aircraft interiors) to 38dB (industrial partitions). For food processing facilities, NSF-certified antimicrobial facings integrate directly with core structures, eliminating contamination risks at joinery points. The latest CNC kerf-cutting technology achieves 0.2mm precision in airflow channeling for ventilation panels requiring directional flow management. Advanced parametric modeling allows engineers to optimize hexagonal cell dimensions for specific loading scenarios - wind tunnel testing confirms custom-configured panels withstand hurricane-force winds exceeding 240km/h without failure. Recent innovations include smart panels with embedded IoT sensors monitoring structural health in real-time, reducing facility inspection costs by 65% annually in pilot projects.

Real-World Application Success Stories

The Copenhagen Airport expansion exemplifies structural ingenuity using honeycomb sandwich technology across 86,000m² of roofing. Specially engineered paneles sándwich de panal

with aerodynamic profiling reduced snow load accumulation by 72% while cutting installation time by 45% versus conventional truss systems. In pharmaceutical manufacturing, Honeywell implemented food-grade ventilation panels achieving ISO Class 5 cleanroom certification through integrated HEPA filtration - reducing particulate contamination by 98.7% annually. Most impressively, Spain's AVE high-speed rail project documented a 17% fuel reduction per carriage after replacing solid composites with advanced aluminum-core panels. Structural analysis confirmed vibration damping increased by 51% while meeting strict European TSI noise emission standards. These applications demonstrate how honeycomb core solutions provide 360-degree performance enhancement beyond basic structural functions.

Future Prospects and Sustainable Innovations

Paneles sándwich de panal are evolving toward closed-loop sustainability as legislation increases recycled content requirements. Next-generation resins under development will incorporate 45-70% post-industrial waste without compromising compression strength, as validated by Fraunhofer Institute testing. The University of Cambridge recently prototyped photovoltaic honeycomb panels generating 18.3W/m² through integrated perovskite cells while maintaining 91% structural efficiency. Revolutionary bio-based cores from mycelium networks show promising lab results - achieving 85% of aluminum's mechanical properties with negative carbon footprints. Major manufacturers are transitioning to solvent-free adhesive systems, eliminating VOC emissions during production by 2026. These advancements position honeycomb core technology as both structurally superior and environmentally responsible - truly intelligent material solutions aligning with global sustainable development goals.

(paneles sándwich de panal)

FAQS on paneles sándwich de panal

Q: What are honeycomb sandwich panels?

A: Honeycomb sandwich panels are lightweight, high-strength structures made of two outer layers and a hexagonal core. They offer excellent thermal insulation and durability for construction and industrial applications.

Q: How do honeycomb ventilation panels work?

A: Honeycomb ventilation panels use a cellular structure to optimize airflow while reducing noise and debris ingress. They are ideal for HVAC systems and building facades requiring efficient air management.

Q: What are the benefits of using honeycomb panels in construction?

A: Honeycomb panels provide superior strength-to-weight ratios, fire resistance, and energy efficiency. Their modular design simplifies installation and reduces maintenance costs over time.

Q: How do honeycomb sandwich panels differ from solid panels?

A: Unlike solid panels, honeycomb sandwich panels are lighter yet stronger due to their core structure. They also offer better thermal and acoustic performance, making them versatile for diverse environments.

Q: Are honeycomb ventilation panels suitable for harsh environments?

A: Yes, honeycomb ventilation panels resist corrosion, extreme temperatures, and moisture. Their robust design ensures longevity in industrial settings or coastal areas with high humidity.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025