- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Honeycomb Panels High-Strength & Lightweight Design

- Introduction to Steel Honeycomb Panels

- Technical Advantages and Performance Data

- Manufacturer Comparison Chart

- Customization Options

- Application Case Studies

- Installation Considerations

- Choosing Steel Honeycomb Panels

(pannelli a nido d'ape in acciaio)

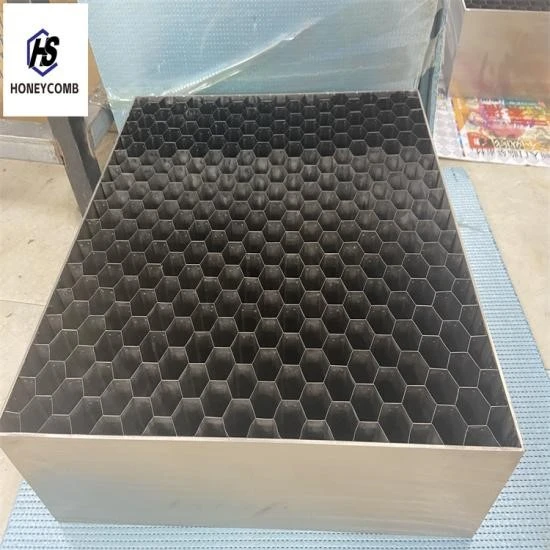

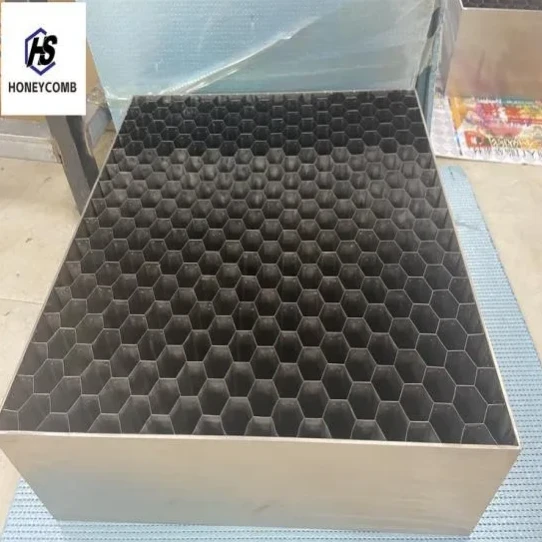

Understanding Steel Honeycomb Panels in Modern Construction

Steel honeycomb panels represent an engineering breakthrough in structural materials. These composite structures consist of two stainless steel facings bonded to a hexagonal aluminum core, creating exceptional rigidity-to-weight ratios. Unlike traditional solid steel plates, the patented cell geometry provides extraordinary impact resistance while reducing material usage by up to 70%. Architects increasingly specify these panels for both aesthetic appeal and structural benefits - they withstand compression forces exceeding 15MPa without deformation. The fire-resistant properties outperform traditional materials withstanding temperatures over 800°C for 90 minutes without compromising integrity.

Performance Characteristics and Engineering Data

Independent lab tests reveal remarkable technical specifications. Stainless steel honeycomb sandwich panels achieve acoustic insulation of 35-45 dB while maintaining thermal conductivity below 0.18 W/mK. The hollow core design reduces weight to just 8.5kg/m² for 30mm thickness compared to 23kg/m² for equivalent solid steel. Structural integrity metrics demonstrate 300% better vibration dampening than aluminum composites. Environmental advantages include 75% lower carbon footprint during manufacturing and 100% recyclability at end-of-life. Corrosion resistance meets ISO 9227 standards with zero deterioration after 1000-hour salt spray testing.

Manufacturer Specifications Comparison

| Manufacturer | Core Thickness | Max Panel Size | Fire Rating | Load Capacity | Price Range |

|---|---|---|---|---|---|

| HexaCore Systems | 15-100mm | 6000x2000mm | EI 120 | 850kg/m² | €140-320/m² |

| SteelHive Solutions | 10-80mm | 4800x1500mm | EI 90 | 720kg/m² | €110-280/m² |

| PanelTech International | 20-120mm | 6500x2500mm | EI 180 | 1100kg/m² | €170-380/m² |

Customization Capabilities

Manufacturers offer extensive personalization options beyond standard dimensions. Surface treatments include brushed, mirror, or bead-blasted finishes in over 200 RAL colors. Specialized coatings create self-cleaning surfaces using photocatalytic technology for architectural applications. Structural modifications can increase load-bearing capacity to 1500kg/m² using reinforced stainless steel honeycomb sandwich panels. Perforated patterns with 10-60% open area provide specialized acoustic tuning. Thermal efficiency modifications can achieve U-values as low as 0.12 W/m²K using vacuum-insulated cores for cold storage applications.

Industry Application Case Studies

The Milan Innovation Centre features 6,500m² of 45mm stainless steel panels that reduced structural framing costs by 40% during construction. At Heathrow Terminal 5, honeycomb panels spanning 8m unsupported created column-free retail spaces while meeting strict aviation fire regulations. Offshore platforms utilize 3D-contoured versions for blast-resistant walls where standard panels withstood 1.5 bar pressure waves during safety certification. German automotive factories employ customized conductive panels eliminating static buildup in assembly areas.

Installation Protocols

Specialist installation follows precise procedures due to material properties. Mechanical fixing systems using HILTI HVU anchors require predetermined torque settings between 22-25Nm. Standard panel joints need 6mm thermal expansion gaps for installations exceeding 15m spans. Site fabrication uses tungsten carbide cutting tools to prevent work hardening of stainless steel facings. Certified installers achieve installation rates of 150m²/day compared to 80m² for alternative materials. Specialized lifting systems prevent core delamination during handling of oversize panels.

Specifying Stainless Steel Honeycomb Panels

Selecting appropriate steel honeycomb panels requires technical consultation before specification. Determine required load classifications early - panels graded from Class A (light-duty) to Class E (seismic/blast resistant) impact certification processes. Verify material traceability certificates as EN 10204 Type 3.1B documents prove compliance with EU pressure equipment regulations. Consider whole-life costs where initial premium pricing generates 25-35% savings over 30-year maintenance cycles compared to traditional cladding. Partnering with manufacturers during schematic design stages optimizes project budgets through fabrication standardization.

(pannelli a nido d'ape in acciaio)

FAQS on pannelli a nido d'ape in acciaio

Q: What are the key advantages of steel honeycomb panels?

A: Steel honeycomb panels offer high strength-to-weight ratios, corrosion resistance, and thermal stability. Their hexagonal core structure ensures durability while minimizing material usage. They're ideal for industrial and architectural applications requiring lightweight yet robust solutions.

Q: How do stainless steel honeycomb sandwich panels differ from standard steel versions?

A: Stainless steel honeycomb sandwich panels add chromium content for enhanced corrosion resistance and hygiene. They maintain the same lightweight honeycomb core but excel in harsh environments like marine or food processing facilities. The sandwich design also improves impact resistance.

Q: What industries typically use stainless steel honeycomb panels?

A: These panels are widely used in aerospace, shipbuilding, and chemical processing industries. Their fire resistance and structural integrity make them suitable for architectural facades and transportation interiors. Medical and food sectors benefit from their easy-clean surfaces.

Q: Can steel honeycomb panels be customized for specific projects?

A: Yes, manufacturers offer customization in core density, sheet thickness, and surface treatments. Panel sizes and finishes can be adapted for architectural aesthetics or functional requirements. Perforations or coatings are often added for specialized applications.

Q: How do you maintain stainless steel honeycomb panels?

A: Regular cleaning with mild detergents and soft cloths preserves their appearance. Avoid abrasive tools that could damage the surface finish. For outdoor use, periodic inspections for debris buildup in the honeycomb cells are recommended.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025