- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 06:19

Back to list

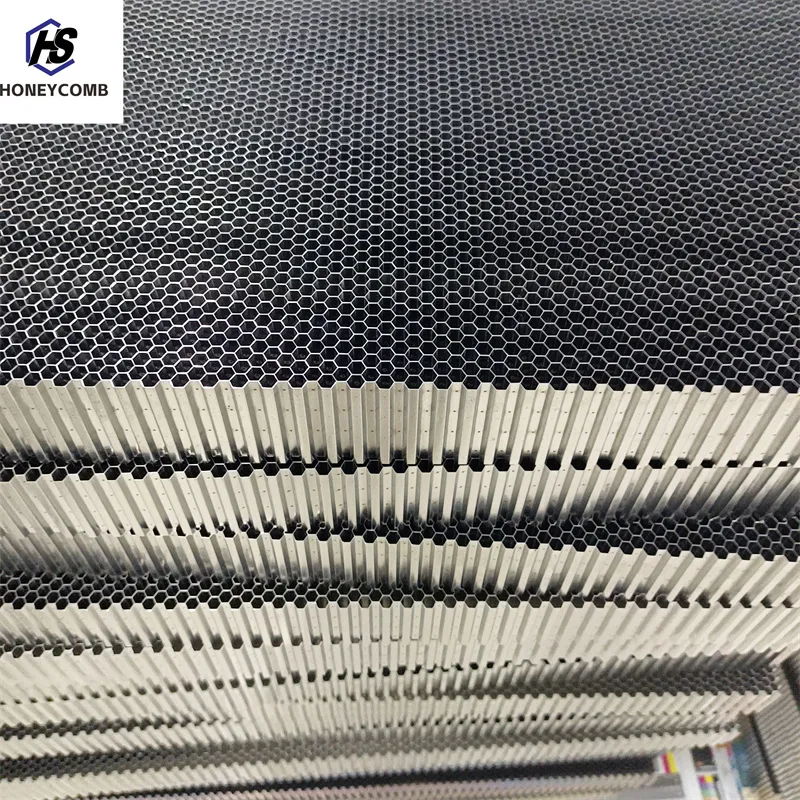

pannello sandwich a nido d'ape

The honeycomb sandwich panel is revolutionizing industries with its exceptional blend of lightweight design and impressive strength. As industries evolve towards more efficient and sustainable solutions, the demand for these innovative panels continues to grow exponentially.

Trustworthiness is paramount, particularly in applications demanding the utmost reliability. Honeycomb sandwich panels hold a solid reputation backed by rigorous testing and certification processes. Standards such as ISO and ASTM provide frameworks to measure performance and ensure compliance with safety regulations, instilling confidence among users. Trusted brands that prioritize quality control from raw material sourcing to final product inspection maintain their esteemed place in the market. These panels are not just about technical specifications; they reflect a strategic approach towards sustainability and efficiency. Their recyclability and environmental impact considerations align with global trends towards green building and manufacturing practices. The adaptability of honeycomb sandwich panels to different contexts, including architectural facades, furniture design, and marine construction, highlights their versatility. Addressing industry-specific challenges often involves combining honeycomb sandwich panels with other advanced technologies for enhanced benefits. Smart building systems, for example, integrate these panels with sensors to monitor structural integrity and energy efficiency, paving the way for smart cities and responsive environments. The interaction between materials and technology fosters innovation-driven growth, positioning honeycomb sandwich panels as a vital component in modern development strategies. Ultimately, the honeycomb sandwich panel exemplifies how simplicity in design can offer complex benefits across industries. Their ability to meet evolving industrial needs with tailored solutions underscores their indispensability. As innovations continue to refine their applications, businesses and industries leveraging these panels are not only investing in state-of-the-art material technology but also in a resilient, sustainable future. In conclusion, the honeycomb sandwich panel serves as an embodiment of engineering excellence, harmonizing lightweight construction with superior strength and efficiency. Its application across diverse sectors, diligent adherence to quality, and unfolding innovations affirm its role as a cornerstone in the quest for technological advancement and environmental stewardship.

Trustworthiness is paramount, particularly in applications demanding the utmost reliability. Honeycomb sandwich panels hold a solid reputation backed by rigorous testing and certification processes. Standards such as ISO and ASTM provide frameworks to measure performance and ensure compliance with safety regulations, instilling confidence among users. Trusted brands that prioritize quality control from raw material sourcing to final product inspection maintain their esteemed place in the market. These panels are not just about technical specifications; they reflect a strategic approach towards sustainability and efficiency. Their recyclability and environmental impact considerations align with global trends towards green building and manufacturing practices. The adaptability of honeycomb sandwich panels to different contexts, including architectural facades, furniture design, and marine construction, highlights their versatility. Addressing industry-specific challenges often involves combining honeycomb sandwich panels with other advanced technologies for enhanced benefits. Smart building systems, for example, integrate these panels with sensors to monitor structural integrity and energy efficiency, paving the way for smart cities and responsive environments. The interaction between materials and technology fosters innovation-driven growth, positioning honeycomb sandwich panels as a vital component in modern development strategies. Ultimately, the honeycomb sandwich panel exemplifies how simplicity in design can offer complex benefits across industries. Their ability to meet evolving industrial needs with tailored solutions underscores their indispensability. As innovations continue to refine their applications, businesses and industries leveraging these panels are not only investing in state-of-the-art material technology but also in a resilient, sustainable future. In conclusion, the honeycomb sandwich panel serves as an embodiment of engineering excellence, harmonizing lightweight construction with superior strength and efficiency. Its application across diverse sectors, diligent adherence to quality, and unfolding innovations affirm its role as a cornerstone in the quest for technological advancement and environmental stewardship.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025