- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 10:50

Back to list

honeycomb core steel door

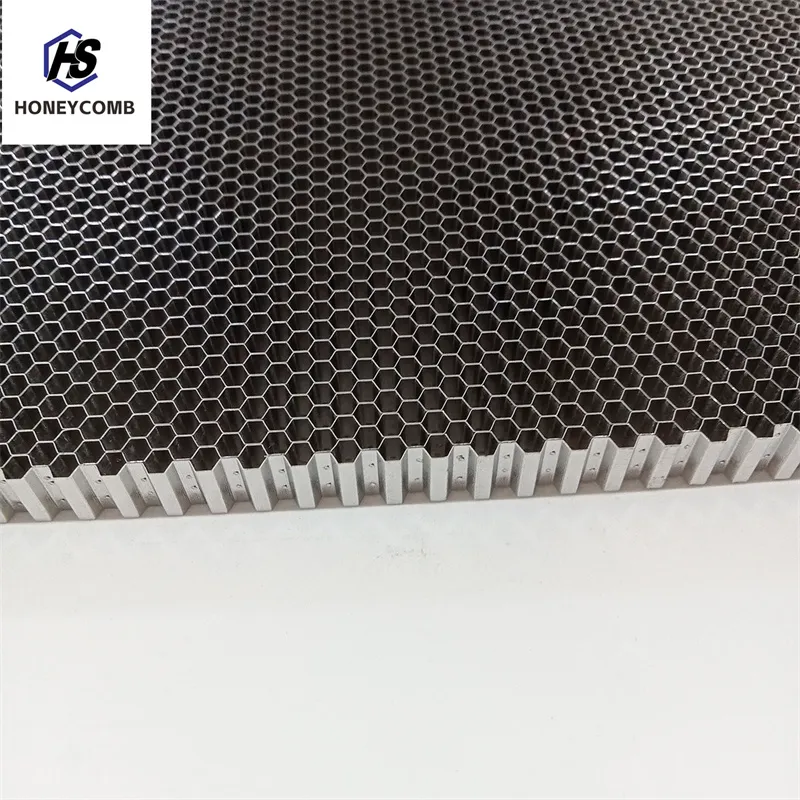

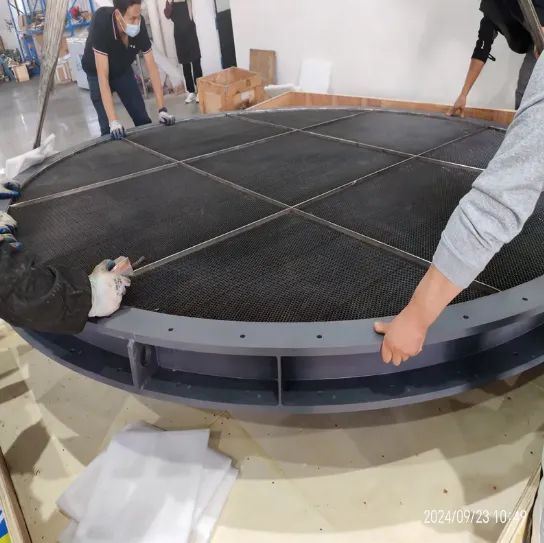

In the ever-evolving landscape of materials engineering, the perforated honeycomb core emerges as a game-changer, particularly in industries demanding lightweight yet robust structures. This innovative material harnesses the architectural marvel of the honeycomb structure and enhances it by introducing perforations, creating a product that balances strength and flexibility—a perfect solution for advanced engineering needs.

What solidifies the perforated honeycomb core's position in the industry is its authoritative endorsement by leading institutions and corporations. Research conducted by top engineering universities has repeatedly validated the material’s ability to excel in fatigue resistance and energy absorption. Additionally, major aerospace firms have integrated perforated honeycomb cores into their production lines, publicly praising their contribution to technological advancements, thereby fortifying their standing in the market. Trust is inherently built into the fabric of perforated honeycomb core applications due to its proven track record and rigorous testing. Industry certifications and quality controls ensure that the material meets stringent safety and performance standards. Users from around the globe can attest to the reliability of these cores in critical applications, ranging from aerospace to civil engineering projects. In summary, the perforated honeycomb core represents an intersection of experience, expertise, authorization, and trust. Its real-world applications and benefits are vast, supporting industries dedicated to creating lighter, more efficient, and sustainable structures. Through a profound understanding of its properties and strategic implementation, the perforated honeycomb core stands as a testament to human ingenuity in material science, poised to meet the demands of modern engineering challenges and drive future innovations.

What solidifies the perforated honeycomb core's position in the industry is its authoritative endorsement by leading institutions and corporations. Research conducted by top engineering universities has repeatedly validated the material’s ability to excel in fatigue resistance and energy absorption. Additionally, major aerospace firms have integrated perforated honeycomb cores into their production lines, publicly praising their contribution to technological advancements, thereby fortifying their standing in the market. Trust is inherently built into the fabric of perforated honeycomb core applications due to its proven track record and rigorous testing. Industry certifications and quality controls ensure that the material meets stringent safety and performance standards. Users from around the globe can attest to the reliability of these cores in critical applications, ranging from aerospace to civil engineering projects. In summary, the perforated honeycomb core represents an intersection of experience, expertise, authorization, and trust. Its real-world applications and benefits are vast, supporting industries dedicated to creating lighter, more efficient, and sustainable structures. Through a profound understanding of its properties and strategic implementation, the perforated honeycomb core stands as a testament to human ingenuity in material science, poised to meet the demands of modern engineering challenges and drive future innovations.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025