- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:38

Back to list

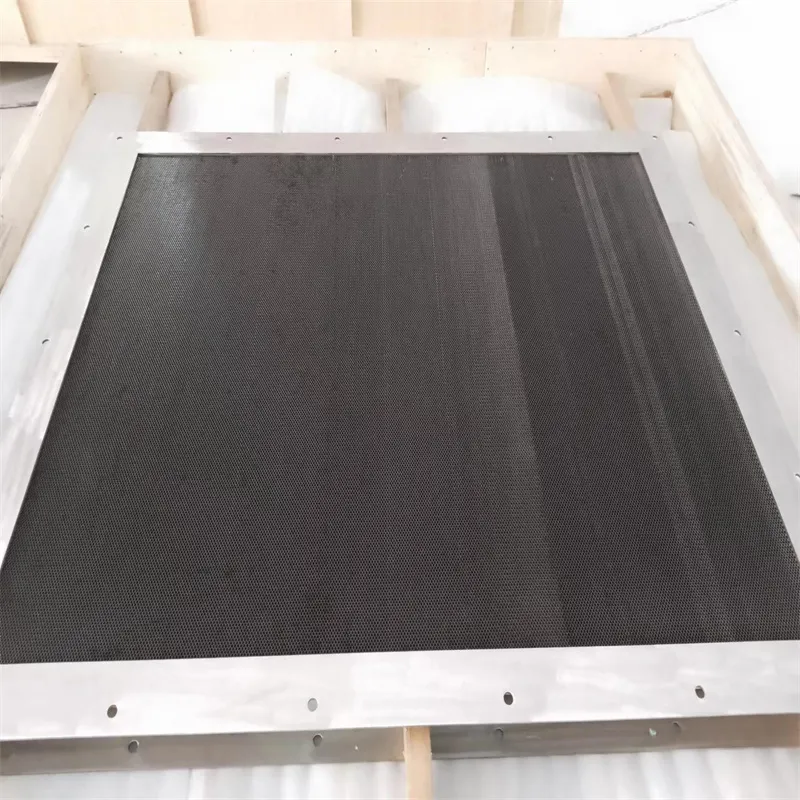

honeycomb core steel door

Perforated honeycomb cores have emerged as a groundbreaking innovation in various industries, offering an optimal blend of strength, light weight, and versatility. These structures are specifically engineered to meet the stringent demands of modern engineering applications, making them indispensable in both aerospace and automotive sectors.

From an expertise standpoint, the development of perforated honeycomb cores requires a thorough understanding of material science, structural engineering, and fabrication techniques. Engineers must accurately calculate the load-bearing capacity and optimize the perforation patterns to achieve desired performance attributes. Advances in computational modeling and simulation have significantly enhanced the design process, enabling customized solutions that cater to specific industry needs. The authority in manufacturing perforated honeycomb cores lies with companies that possess state-of-the-art technology and rigorous quality control protocols. Such manufacturers utilize precision machinery and employ skilled professionals to ensure consistency and reliability in their products. The certification of these cores by industry standards further bolsters their credibility and acceptance across various sectors. Trust in perforated honeycomb cores is built through demonstrable performance and longevity in real-world applications. Case studies often illustrate the life-cycle benefits and cost-effectiveness of these materials, offering compelling evidence to potential adopters. Feedback from end users in aerospace, automotive, and construction industries reinforces the reputation of perforated honeycomb cores as a trustworthy solution for modern engineering challenges. In conclusion, perforated honeycomb cores represent a pivotal advancement in material science, providing essential benefits in terms of strength, weight, and efficiency. Their application across multiple sectors underscores their significance in driving innovation and sustainability in engineering practices. Embracing these materials can lead to transformative benefits, reinforcing the importance of continued research and development in this domain.

From an expertise standpoint, the development of perforated honeycomb cores requires a thorough understanding of material science, structural engineering, and fabrication techniques. Engineers must accurately calculate the load-bearing capacity and optimize the perforation patterns to achieve desired performance attributes. Advances in computational modeling and simulation have significantly enhanced the design process, enabling customized solutions that cater to specific industry needs. The authority in manufacturing perforated honeycomb cores lies with companies that possess state-of-the-art technology and rigorous quality control protocols. Such manufacturers utilize precision machinery and employ skilled professionals to ensure consistency and reliability in their products. The certification of these cores by industry standards further bolsters their credibility and acceptance across various sectors. Trust in perforated honeycomb cores is built through demonstrable performance and longevity in real-world applications. Case studies often illustrate the life-cycle benefits and cost-effectiveness of these materials, offering compelling evidence to potential adopters. Feedback from end users in aerospace, automotive, and construction industries reinforces the reputation of perforated honeycomb cores as a trustworthy solution for modern engineering challenges. In conclusion, perforated honeycomb cores represent a pivotal advancement in material science, providing essential benefits in terms of strength, weight, and efficiency. Their application across multiple sectors underscores their significance in driving innovation and sustainability in engineering practices. Embracing these materials can lead to transformative benefits, reinforcing the importance of continued research and development in this domain.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025