- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 12:13

Back to list

honeycomb core steel door

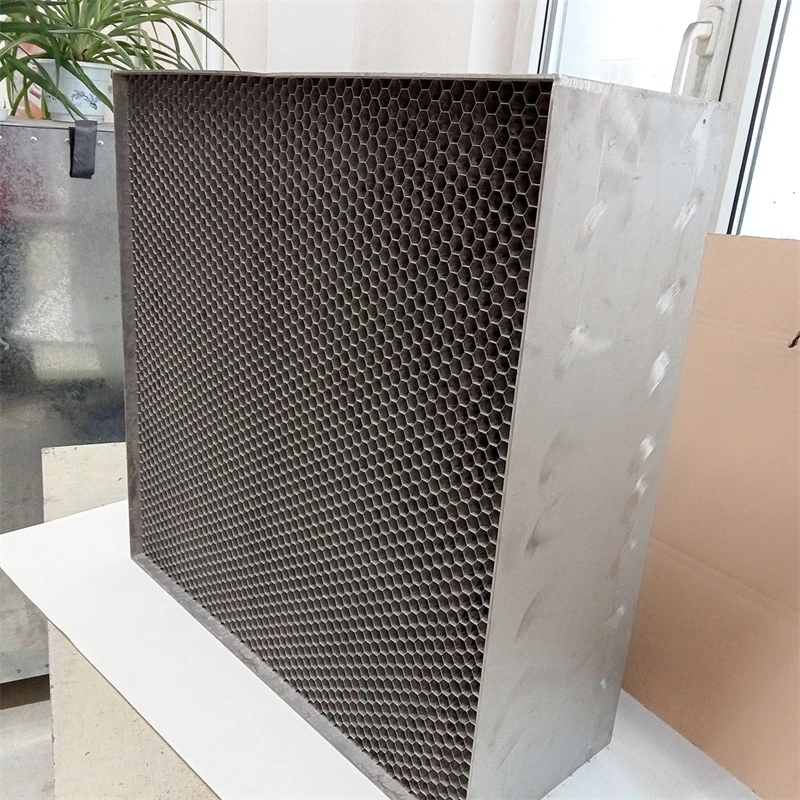

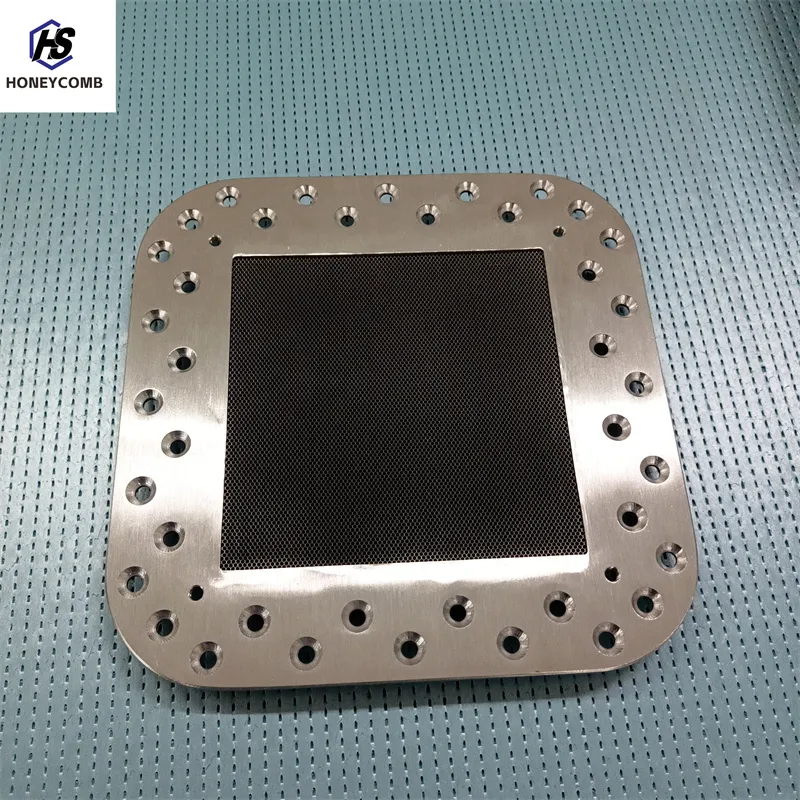

Perforated honeycomb cores are revolutionizing the landscape of lightweight, high-strength material solutions across multiple industries. The increasing demand for materials that offer exceptional weight-to-strength ratios has led to the innovative utilization of these cores in applications ranging from aerospace and automotive to construction and packaging.

The authority in the industry lies in its commitment to rigorous testing and certification of perforated honeycomb cores to meet international safety and quality standards. Manufacturers invest significantly in research and development, ensuring these cores can withstand varied environmental conditions and stress factors. Their compliance with ISO and ASTM standards further solidifies their reliability and applicability across diverse sectors. When considering trustworthiness, the transparency in the sourcing and processing of materials for perforated honeycomb cores plays a vital role. High-quality raw materials and environmentally friendly manufacturing processes are crucial in establishing consumer and industry trust. Leading producers often partner with certification bodies to ensure that their products not only meet regulatory requirements but also exceed customer expectations. Innovation continues to drive the evolution of perforated honeycomb cores, with advances in material science promising even greater improvements in performance and sustainability. The introduction of bio-based composites and smart materials into honeycomb designs is set to address future demands for eco-friendly, high-performance materials. In conclusion, perforated honeycomb cores represent a pinnacle of materials engineering—melding expertise, experience, authority, and trustworthiness into a product that meets the ever-evolving demands of modern industries. As technological advancements persist, so too will the capacities and applications of these dynamic materials, proving indispensable in the quest for efficient, sustainable solutions.

The authority in the industry lies in its commitment to rigorous testing and certification of perforated honeycomb cores to meet international safety and quality standards. Manufacturers invest significantly in research and development, ensuring these cores can withstand varied environmental conditions and stress factors. Their compliance with ISO and ASTM standards further solidifies their reliability and applicability across diverse sectors. When considering trustworthiness, the transparency in the sourcing and processing of materials for perforated honeycomb cores plays a vital role. High-quality raw materials and environmentally friendly manufacturing processes are crucial in establishing consumer and industry trust. Leading producers often partner with certification bodies to ensure that their products not only meet regulatory requirements but also exceed customer expectations. Innovation continues to drive the evolution of perforated honeycomb cores, with advances in material science promising even greater improvements in performance and sustainability. The introduction of bio-based composites and smart materials into honeycomb designs is set to address future demands for eco-friendly, high-performance materials. In conclusion, perforated honeycomb cores represent a pinnacle of materials engineering—melding expertise, experience, authority, and trustworthiness into a product that meets the ever-evolving demands of modern industries. As technological advancements persist, so too will the capacities and applications of these dynamic materials, proving indispensable in the quest for efficient, sustainable solutions.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025