- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 12:38

Back to list

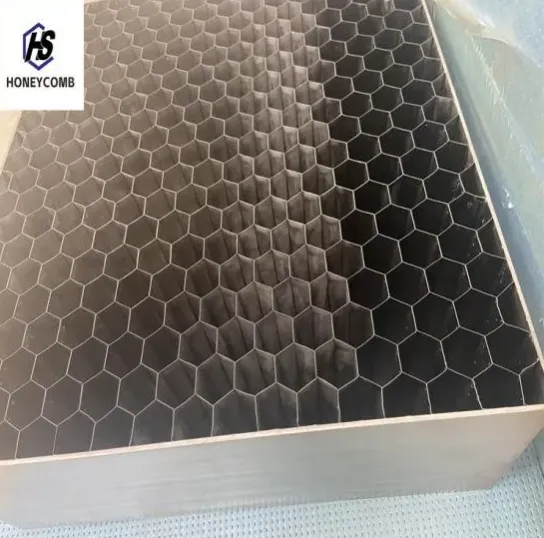

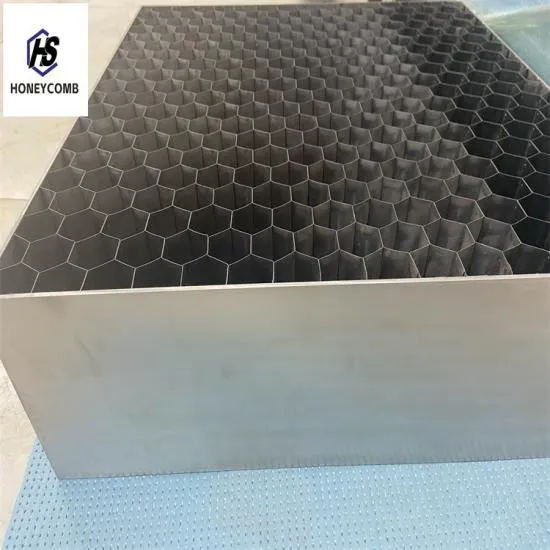

honeycomb core steel door

Perforated honeycomb cores have revolutionized industries ranging from aerospace to architecture with their unique structural benefits. Having been utilized in numerous applications, these cores are not only an embodiment of engineering excellence but also a testament to innovative material science.

In the automotive sector, manufacturers are exploring the use of perforated honeycomb cores to enhance vehicle safety and efficiency simultaneously. These cores serve as integral parts of crash absorption zones, maintaining passenger safety by distributing impact forces. Their lightweight nature contributes to better vehicle handling and reduced emissions, aligning with the industry's shift towards sustainable practices. From an engineering perspective, the production process of perforated honeycomb cores involves meticulous precision. Engineers must account for the material’s cellular structure to maintain uniformity and ensure the perforations do not compromise the core’s integrity. This requires an expert understanding of material properties and advanced fabrication techniques, further testament to the expertise involved in their production. Companies manufacturing these innovative cores are subject to stringent regulatory standards, guaranteeing the highest level of quality and reliability. This assurance positions these products as authoritative choices in their respective industries, underlining their trustworthiness. Continuous research and development efforts ensure that perforated honeycomb cores evolve, meeting future demands of high-performance materials. In summary, perforated honeycomb cores exemplify the marriage of advanced engineering and material science, offering unparalleled benefits across various industries. As the world increasingly prioritizes efficiency and sustainability, these cores stand out as an indispensable component, promising innovation and reliability for the future.

In the automotive sector, manufacturers are exploring the use of perforated honeycomb cores to enhance vehicle safety and efficiency simultaneously. These cores serve as integral parts of crash absorption zones, maintaining passenger safety by distributing impact forces. Their lightweight nature contributes to better vehicle handling and reduced emissions, aligning with the industry's shift towards sustainable practices. From an engineering perspective, the production process of perforated honeycomb cores involves meticulous precision. Engineers must account for the material’s cellular structure to maintain uniformity and ensure the perforations do not compromise the core’s integrity. This requires an expert understanding of material properties and advanced fabrication techniques, further testament to the expertise involved in their production. Companies manufacturing these innovative cores are subject to stringent regulatory standards, guaranteeing the highest level of quality and reliability. This assurance positions these products as authoritative choices in their respective industries, underlining their trustworthiness. Continuous research and development efforts ensure that perforated honeycomb cores evolve, meeting future demands of high-performance materials. In summary, perforated honeycomb cores exemplify the marriage of advanced engineering and material science, offering unparalleled benefits across various industries. As the world increasingly prioritizes efficiency and sustainability, these cores stand out as an indispensable component, promising innovation and reliability for the future.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025