- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 13:25

Back to list

prese d'aria a nido d'ape emi

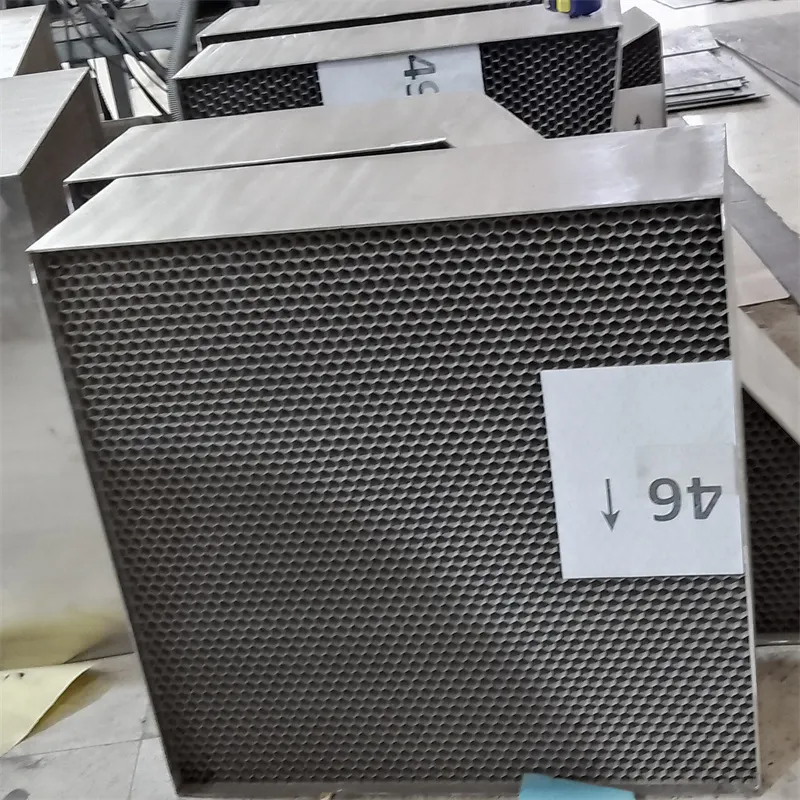

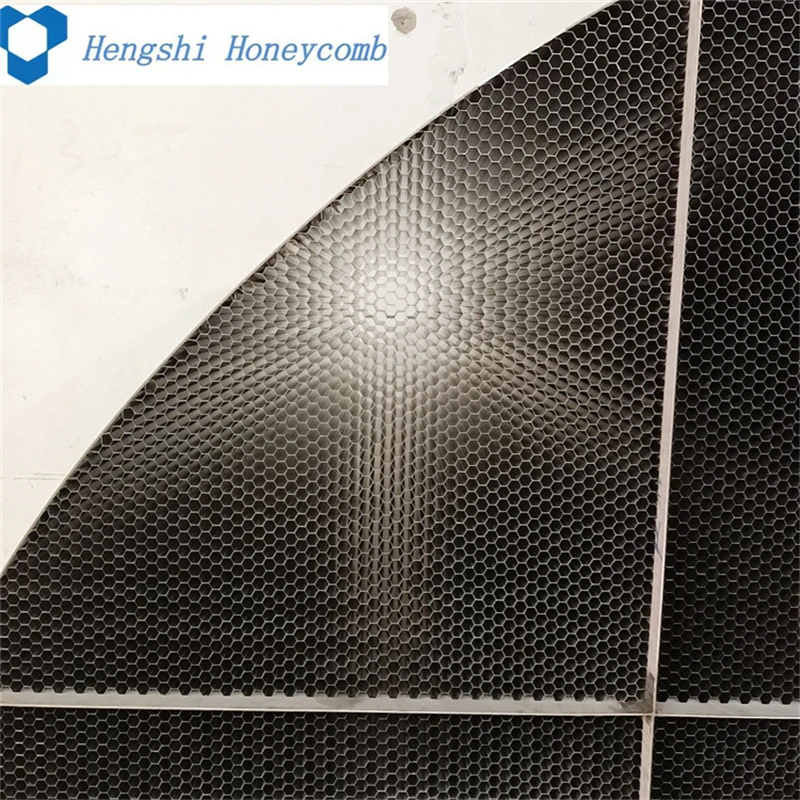

Honeycomb EMI air vents, commonly referred to as Prese d'aria a nido d'ape EMI, are a remarkable innovation in the field of electromagnetic interference protection. These vents are indispensable in various industries, known for their exceptional performance in safeguarding sensitive electronic equipment from electromagnetic disturbances. This article explores the nuances of honeycomb EMI air vents, highlighting their applications, benefits, and key features.

From an engineering perspective, the installation of honeycomb EMI air vents is a straightforward process, typically requiring only standard tools and procedures. Their robustness and durability make them suitable for various environmental conditions, adding to their versatility. Moreover, they come in a variety of materials, including aluminum, brass, and steel, allowing for customization to suit specific application needs. The expertise involved in manufacturing honeycomb EMI air vents cannot be overstated. Each vent is the result of meticulous design and engineering, ensuring that it not only meets but exceeds industry standards. Manufacturers with decades of experience bring a wealth of knowledge and innovation to the table, constantly improving designs to offer enhanced performance and reliability. In terms of maintenance, honeycomb EMI air vents require minimal upkeep. Regular cleaning to remove dust and debris suffices, ensuring that airflow is not obstructed and the shielding effectiveness remains uncompromised. This ease of maintenance further solidifies their position as a cost-effective solution for managing electromagnetic interference. Investing in honeycomb EMI air vents is not just about protection—it is about guaranteeing the integrity and performance of critical electronic systems. While the initial cost may appear high, the long-term benefits, including reduced downtime and extended equipment life, make them a prudent choice for businesses committed to maintaining operational excellence. In conclusion, honeycomb EMI air vents are an essential component in the landscape of modern electronics. Their ability to provide effective electromagnetic shielding while ensuring adequate ventilation makes them a sought-after solution across various industries. As technology continues to advance, the role of honeycomb EMI air vents in safeguarding our electronic infrastructure will undeniably grow, underscoring their importance in achieving both regulatory compliance and operational reliability.

From an engineering perspective, the installation of honeycomb EMI air vents is a straightforward process, typically requiring only standard tools and procedures. Their robustness and durability make them suitable for various environmental conditions, adding to their versatility. Moreover, they come in a variety of materials, including aluminum, brass, and steel, allowing for customization to suit specific application needs. The expertise involved in manufacturing honeycomb EMI air vents cannot be overstated. Each vent is the result of meticulous design and engineering, ensuring that it not only meets but exceeds industry standards. Manufacturers with decades of experience bring a wealth of knowledge and innovation to the table, constantly improving designs to offer enhanced performance and reliability. In terms of maintenance, honeycomb EMI air vents require minimal upkeep. Regular cleaning to remove dust and debris suffices, ensuring that airflow is not obstructed and the shielding effectiveness remains uncompromised. This ease of maintenance further solidifies their position as a cost-effective solution for managing electromagnetic interference. Investing in honeycomb EMI air vents is not just about protection—it is about guaranteeing the integrity and performance of critical electronic systems. While the initial cost may appear high, the long-term benefits, including reduced downtime and extended equipment life, make them a prudent choice for businesses committed to maintaining operational excellence. In conclusion, honeycomb EMI air vents are an essential component in the landscape of modern electronics. Their ability to provide effective electromagnetic shielding while ensuring adequate ventilation makes them a sought-after solution across various industries. As technology continues to advance, the role of honeycomb EMI air vents in safeguarding our electronic infrastructure will undeniably grow, underscoring their importance in achieving both regulatory compliance and operational reliability.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025